Continuous treatment method for improving surface performance of carbon fibers

A technology of surface properties and treatment methods, which is applied in fiber treatment, carbon fiber, ultrasonic/sonic fiber treatment, etc., can solve the problems of uneven surface structure performance, increase post-treatment process, and decrease in fiber strength, so as to achieve convenient preparation and improve carbon fiber Mechanical properties, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

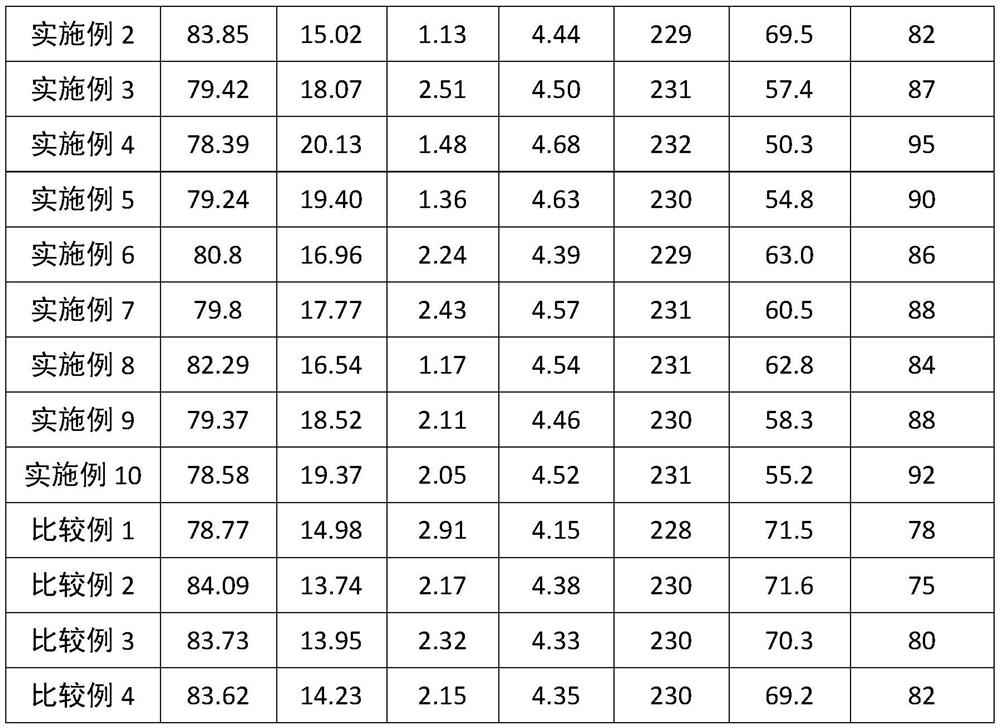

[0032] High-temperature carbonized carbon fiber is used as the raw material for surface treatment. The fiber specification is 12K, the bundle strength is 4.36GPa, and the modulus is 230GPa. Continuous surface treatment: wire speed, grafting liquid type and molar concentration, plasma gas type and flow rate, discharge Power, sizing agent mass concentration, and drying temperature, the process parameters are shown in Table 1; the sizing agent adopts bisphenol A epoxy resin emulsion type sizing agent (Shell EPON-828 and EPON-1001, the mass ratio of the two is 40 / 60) Finally roll up. The fiber properties after continuous surface treatment were tested, and the test results are shown in Table 2.

Embodiment 9

[0034] The carbon fiber after high temperature carbonization is adopted as the surface treatment raw material, the fiber specification is 24K, the bundle strength is 4.32GPa, and the modulus is 230GPa. The continuous surface treatment process parameters are shown in Table 1; EPON-828 and EPON-1001, the mass ratio of the two is 43 / 57), and finally wind up. The fiber properties after continuous surface treatment were tested, and the test results are shown in Table 2.

Embodiment 10

[0036] The carbon fiber after high temperature carbonization is adopted as the surface treatment raw material, the fiber specification is 48K, the bundle strength is 4.33GPa, and the modulus is 230GPa. The continuous surface treatment process parameters are shown in Table 1; EPON-828 and EPON-1001, the mass ratio of the two is 45 / 55), and finally wind up. The fiber properties after continuous surface treatment were tested, and the test results are shown in Table 2.

[0037] The surface treatment process parameter of table 1 embodiment 1-10

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com