Epoxy resin copper-clad plate and preparation method thereof

A technology of epoxy resin and epoxy resin solution, used in epoxy resin glue, chemical instruments and methods, other household appliances, etc., can solve the problems of affecting the performance and quality of copper clad laminates, poor effect, lack of flame retardant performance, etc. , to achieve good flame retardancy, improve flame retardancy, heat resistance and working temperature promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Please refer to figure 1 As shown, an epoxy resin copper clad laminate includes a prepreg 10, both sides of the prepreg 10 are laminated with copper foil 20, and the prepreg 10 is made by intruding glass fiber cloth into modified epoxy resin glue and pretreatment in an oven.

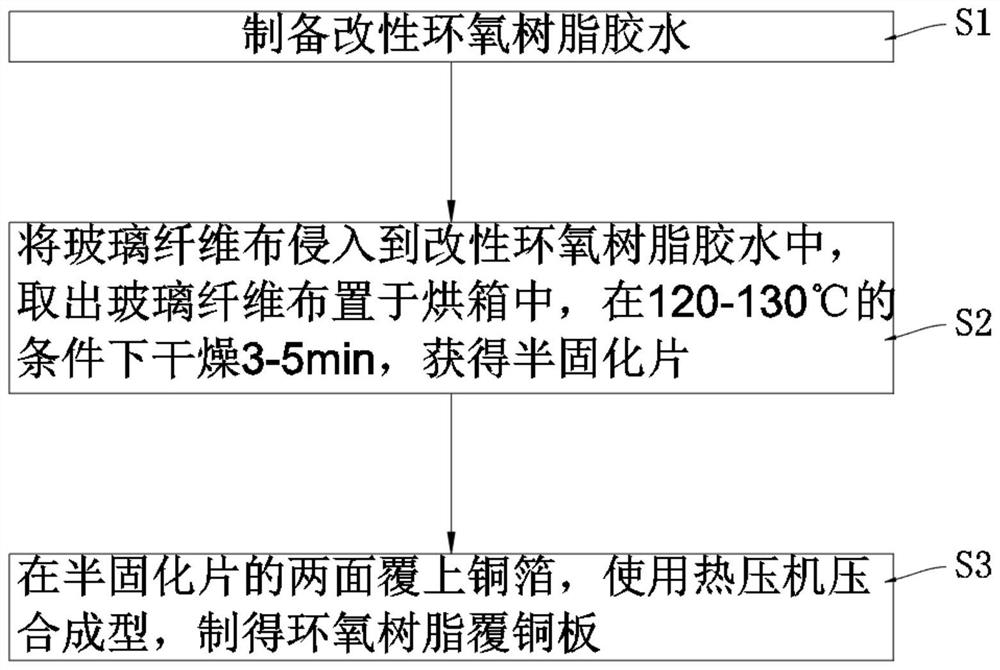

[0043] Please refer to figure 2 Shown, the present invention also provides a kind of preparation method of epoxy resin copper clad laminate, comprises the following steps:

[0044] Step 1, prepare modified epoxy resin glue.

[0045] Prepare modified epoxy resin glue, comprise the following steps:

[0046] 101), adding the epoxy resin solution into the mixer, and adding thermally conductive fillers into the mixer, and stirring for 25 minutes under the condition that the rotation speed is 1100r / min.

[0047]102), add flame retardant, diaminodiphenyl sulfone and boron trifluoride triethylphosphine to the mixer in step 101), and stir for 20min under the condition of 1500r / min at a rotating speed, ...

Embodiment 2

[0059] An epoxy resin copper-clad laminate provided in this embodiment and its preparation method are roughly the same as in Embodiment 1, the main difference being:

[0060] In step 101), stirring for 27min under the condition that the rotating speed is 1150r / min;

[0061] In step 102), under the condition that the rotating speed is 1700r / min, stir for 25min to prepare modified epoxy resin glue;

[0062] In the preparation method of the epoxy resin solution: under the condition that the rotating speed is 900r / min, stir for 11min;

[0063] In the method of preparing the flame retardant: Stir at 85°C for 20 minutes to obtain a mixed solution, adjust the pH of the mixed solution to 5; polymerize at 77°C for 5 hours to obtain a polymer, mix the polymer with water and ethanol Washed 6 times, and then vacuum dried for 48 hours to obtain a flame retardant.

[0064] The emulsifier is fatty acid soap;

Embodiment 3

[0066] An epoxy resin copper-clad laminate provided in this embodiment and its preparation method are roughly the same as in Embodiment 1, the main difference being:

[0067] In step 101), stirring for 30min under the condition that the rotation speed is 1200r / min;

[0068] In step 102), under the condition that the rotating speed is 2000r / min, stir for 30min to prepare modified epoxy resin glue;

[0069] In the preparation method of the epoxy resin solution: under the condition that the rotating speed is 1000r / min, stir for 12min;

[0070] In the method of preparing the flame retardant: stir at 90°C for 20 minutes to obtain a mixed solution, adjust the pH value of the mixed solution to 5; polymerize at 80°C for 5 hours to obtain a polymer, mix the polymer with water and ethanol Washed 8 times, and then vacuum dried for 48 hours to obtain a flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com