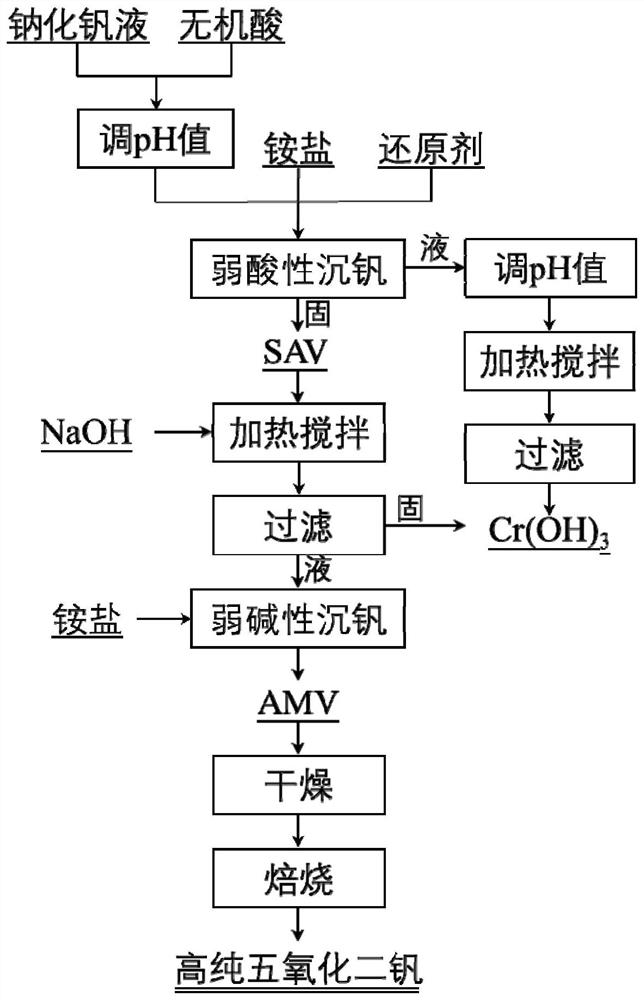

Method for preparing high-purity vanadium pentoxide from sodium vanadium solution through two-step method

A technology of vanadium pentoxide and vanadium liquid, applied in the direction of vanadium oxide, etc., can solve the problems of complex process flow, introduction of impurity ions, and low product purity, and achieve the effects of simple process, high vanadium yield, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is used to illustrate the method that sodium vanadium solution two-step method of the present invention prepares high-purity vanadium pentoxide.

[0047] (1) Measure 500ml of sodium vanadium solution, add sulfuric acid dropwise to adjust the pH to neutral, add 30ml of vanadyl sulfate solution with a concentration of 2.85mol / L, then add sulfuric acid dropwise to control the pH to 4.0, then add 26.23g of sulfuric acid Ammonium, stirred and reacted at 100°C for 0.5h. After the reaction is finished, filter to obtain the vanadium-precipitated product, wash the vanadium-precipitated product twice with deionized water, filter and dry to obtain SAV.

[0048] (2) Dissolve the dried SAV in sodium hydroxide solution, control the end point pH value to 10.5, stir and react at 90°C for 12 hours, filter to obtain dark green filter cake and 515ml colorless vanadium solution, TV is 41.2g / L.

[0049] (3) Add 53.26g ammonium sulfate in described colorless vanadium solutio...

Embodiment 2

[0052] This embodiment is used to illustrate the method that sodium vanadium solution two-step method of the present invention prepares high-purity vanadium pentoxide.

[0053] (1) Measure 500ml of sodium vanadium solution, first drop sulfuric acid to adjust the pH to neutral, add 23g dihydrate oxalic acid, then add dropwise sulfuric acid to control the pH to 5.0, then add 34.93g ammonium bicarbonate (NH 3 content of about 21wt%), stirred and reacted at 50°C for 3h. After the reaction is finished, filter to obtain the vanadium-precipitated product, wash the vanadium-precipitated product twice with deionized water, filter and dry to obtain SAV.

[0054] (2) Dissolve the dried SAV in sodium hydroxide solution, control the end point pH value to 11, stir and react at 95°C for 9h, filter to obtain dark green filter cake and 490ml colorless vanadium solution, TV is 39.4g / L.

[0055] (3) Add 71g ammonium bicarbonate in described colorless vanadium solution, stir reaction 1h, filter ...

Embodiment 3

[0058] This embodiment is used to illustrate the method that sodium vanadium solution two-step method of the present invention prepares high-purity vanadium pentoxide.

[0059] (1) Measure 500ml of sodium vanadium solution, add sulfuric acid dropwise to adjust the pH to neutral, add 10.7g sodium sulfite, then add sulfuric acid dropwise to control the pH to 5.5, then add 25.17g ammonium chloride, and stir the reaction at 85°C 1h. After the reaction is finished, the vanadium precipitation product is obtained by filtration, and the vanadium precipitation product is beaten and washed twice with deionized water, filtered and dried to obtain SAV.

[0060] (2) Dissolve the dried SAV in sodium hydroxide solution, control the end point pH to 11.5, stir and react at 98°C for 3h, filter to obtain dark green filter cake and 490ml colorless vanadium solution, TV is 41.5g / L.

[0061] (3) Add 57.6g ammonium chloride in described colorless vanadium solution, stir reaction 2h, filter after re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com