Quick-setting high-alkali-activated fly ash cementing material capable of being maintained at normal temperature and preparation method of quick-setting high-alkali-activated fly ash cementing material

A technology for cementitious materials and fly ash, applied in the field of building materials, can solve the problems of low order, no water reducing agent products, and inability to achieve large-scale application in a short period of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

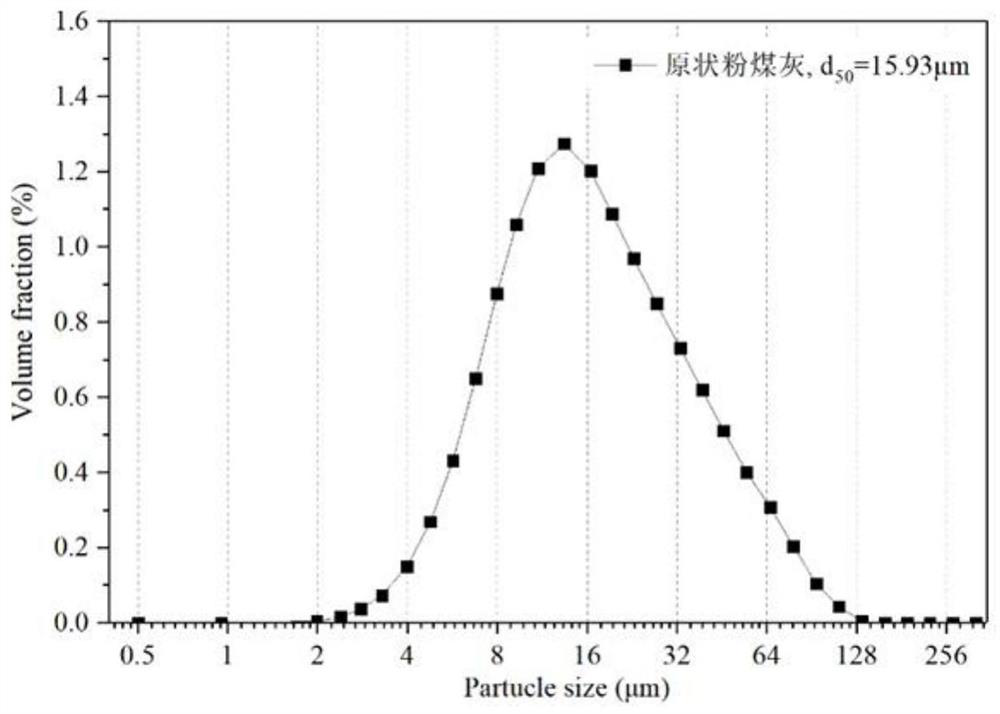

[0034] In Example 1-4, a fast-setting high-strength alkali-activated fly ash cementitious material that can be cured at room temperature and its preparation method, its raw materials include the following components: 30-50 parts of undisturbed fly ash, high-activity super 50-70 parts of fine fly ash, 12-18 parts of sodium hydroxide (see Table 2 for details).

[0035] The specific preparation method is divided into two steps:

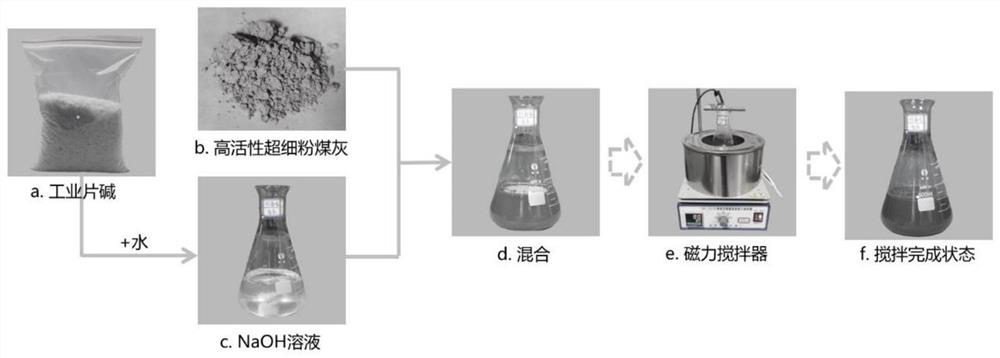

[0036] (1) Preparation of pre-excitation solution: Add 2 to 3 parts of highly active ultrafine fly ash into the prepared sodium hydroxide solution, dissolve and heat for 20 minutes at 80°C and 800r / min with a magnetic stirrer, and wait for After cooling, it becomes the pre-excitation solution. The specific process is as follows: figure 1 shown.

[0037] (2) Preparation and maintenance of alkali-activated fly ash cementitious material: mix the pre-excited solution as an alkali activator with the remaining fly ash raw materials, stir and prepare samples,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial setting time | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com