Memory, refining process full-flow simulation method, device and equipment

A simulation method and technology of the whole process, applied in the field of chemical production, can solve the problems of poor accuracy, error, large error, etc., to avoid errors, improve accuracy, and reduce the link of introducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

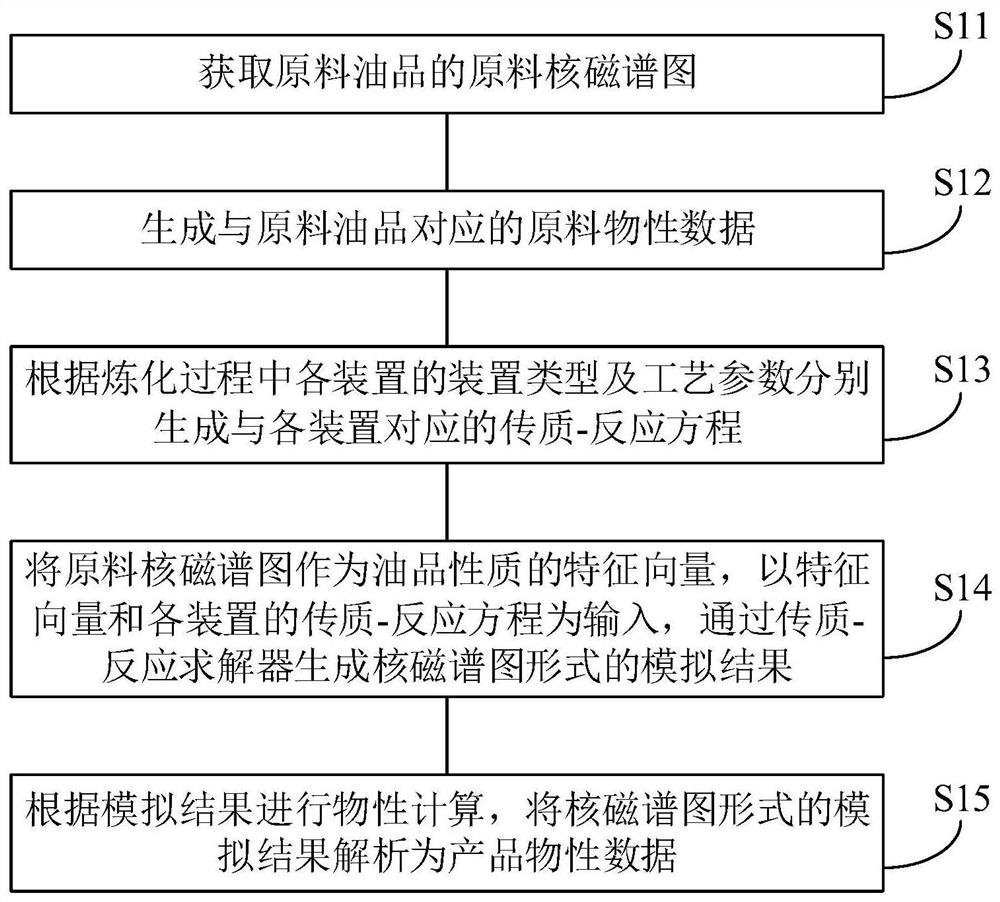

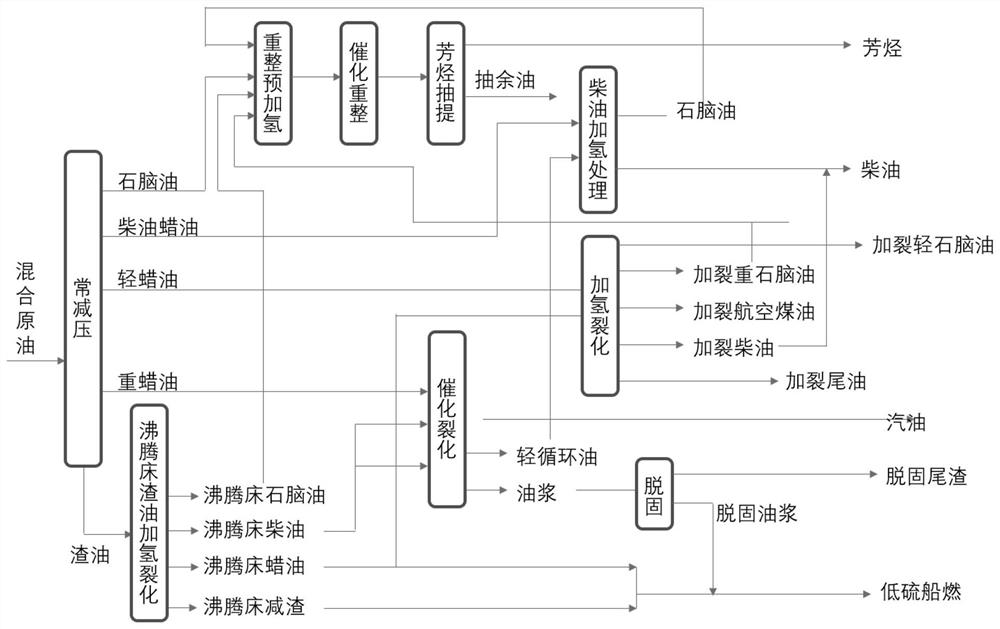

[0069] In order to improve the accuracy of the results when simulating the refining process, such as figure 1 As shown, in the embodiment of the present invention, a method for simulating the whole process of refining and chemical process is provided, including steps:

[0070] S11. Obtain the raw material nuclear magnetic spectrum of the raw oil product;

[0071] In the embodiment of the present invention, nuclear magnetic resonance technology is first used to generate a corresponding nuclear magnetic spectrum according to the mixed crude oil. In the embodiment of the present invention, the nuclear magnetic spectrum generated according to the mixed crude oil may be referred to as a raw material nuclear magnetic spectrum. The raw oil product in the embodiment of the present invention refers to the refining feed, such as mixed crude oil, naphtha or gasoline and diesel oil.

[0072] In practical applications, the data required for the simulation of the whole refining process al...

Embodiment 1

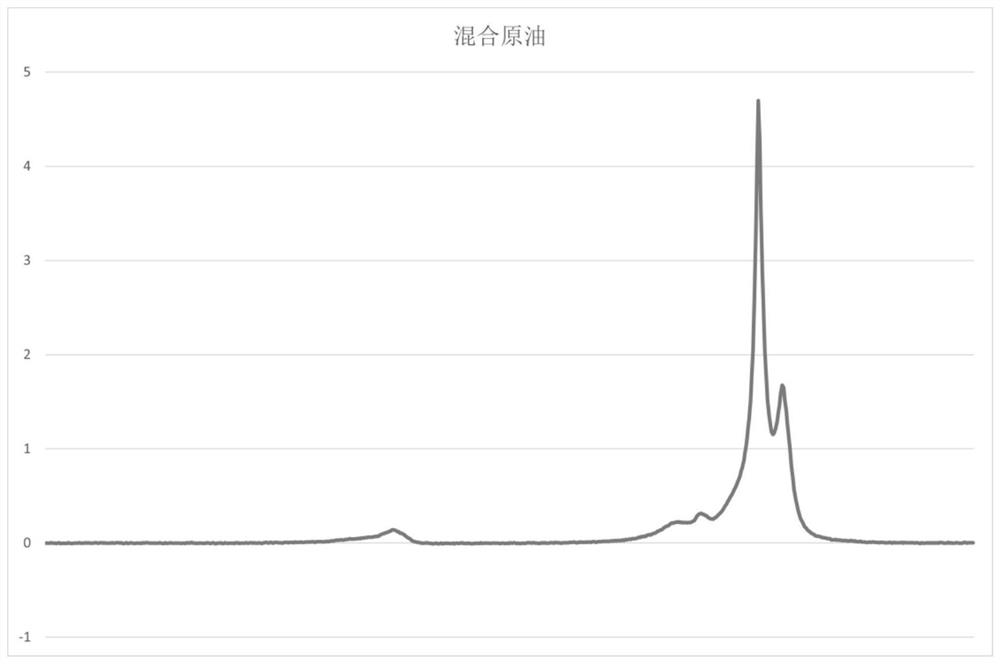

[0100] The raw material NMR spectrum of embodiment 1 is shown in figure 2 ; After the calculation and simulation of the whole process, the NMR spectra of each product are obtained as shown in Figure 4 .

example 1

[0101] The raw material and product properties of example 1 are compared with the properties predicted by simulation calculation in Table 1;

[0102] Table 1

[0103]

[0104]

[0105] Note: The whole fraction data in Table 1 is TBP, and the others are D86 data.

[0106] The above is the specific simulation result obtained in an example (Example 1) and the error value of the simulation result according to the method for simulating the whole refining process in the embodiment of the present invention.

[0107] It can be seen from the above that the calculation accuracy of the method provided by the embodiment of the present invention is relatively high, and the unified spectrogram data system can be used to run through the entire refining process, avoiding the mismatch and conversion of oil product property analysis data formats between different devices caused by the error.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com