Optical fiber raw material composition, optical fiber, and optical fiber product

A raw material composition and optical fiber core technology, which is applied in the direction of cladding optical fiber, lasers, laser components, etc., can solve the problems of unable to cover the working bandwidth, narrow stimulated emission cross-section, poor working stability of the optical fiber, etc., to improve the service life And work stability, strong anti-deliquescence function, low-loss welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] In yet another aspect, the embodiments of the present disclosure also provide a method for preparing an optical fiber. The method for preparing an optical fiber includes: using the above-mentioned optical fiber raw material composition provided by the embodiments of the present disclosure to prepare an optical fiber.

[0090] Exemplarily, the preparation method includes: using an optical fiber raw material composition for optical fiber cladding to prepare an optical fiber cladding prefabricated tube. The optical fiber core prefabricated rod is prepared by using the optical fiber raw material composition for the optical fiber core. The optical fiber is prepared by the tube rod method by using the optical fiber cladding prefabricated tube and the optical fiber core prefabricated rod.

[0091] The following is an exemplary description of the operation process of preparing a single-clad optical fiber by the tube-and-rod method:

[0092] (1) Determine the specific compositi...

Embodiment 1

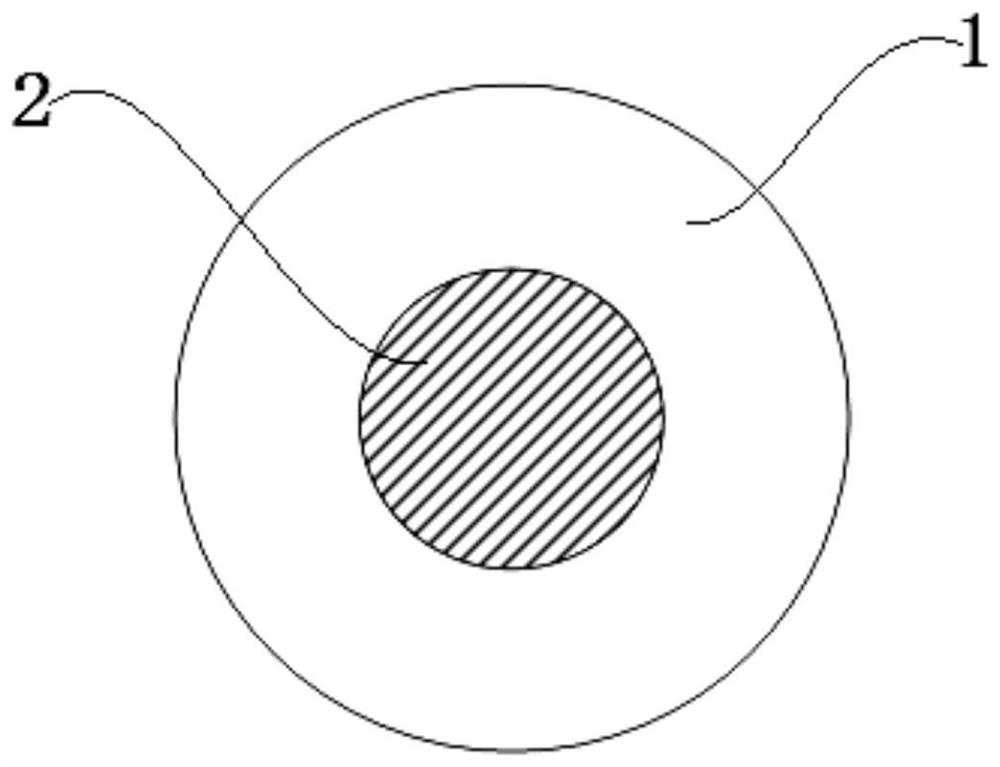

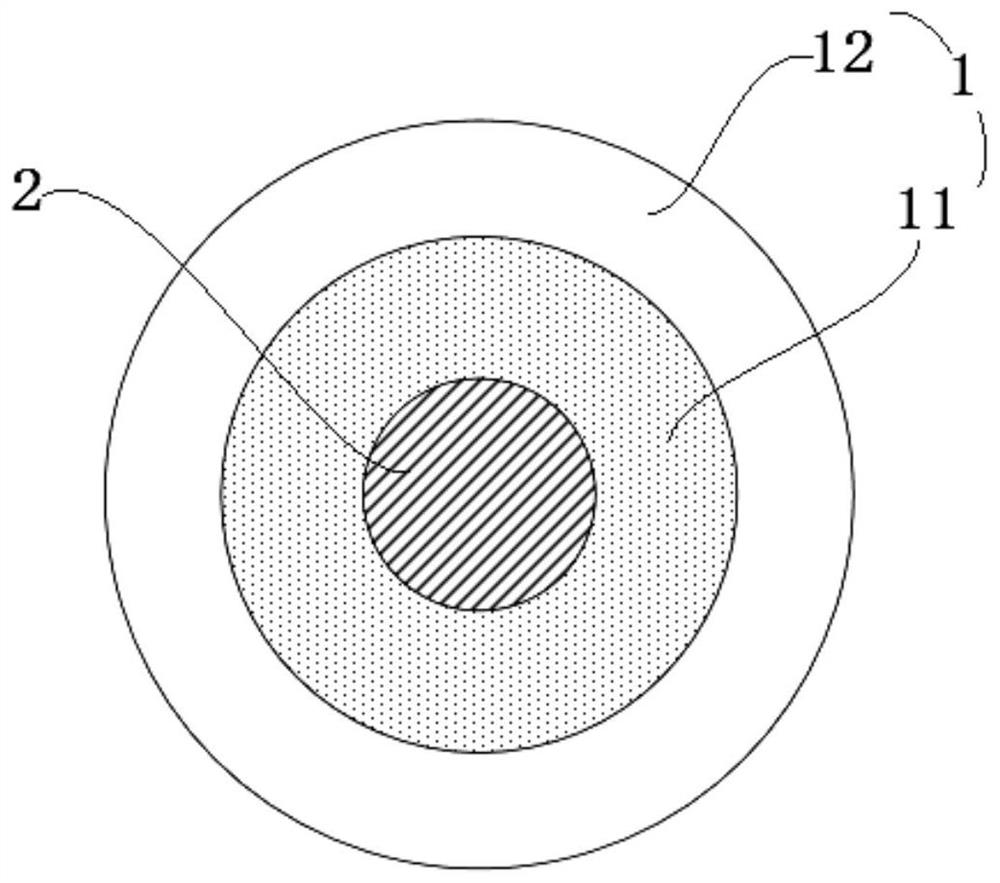

[0099] The present embodiment 1 provides a series of erbium-doped optical fibers, which include an optical fiber core and an optical fiber cladding, wherein the composition of the optical fiber core and the optical fiber cladding is shown in Table 1 and Table 2, and in Table 1 and Table 2 The ratios involved in each component are mole percentages:

[0100] Table 1

[0101]

[0102] Table 2

[0103]

[0104] The preparation steps of the above six kinds of erbium-doped optical fibers involved in embodiment 1 refer to the following description:

[0105] (1) According to the specific composition of the raw material composition for preparing the fiber core and cladding in Table 1, determine the quality of each component wherein, and take each component according to the quality of each component, mix each component, and Grinding in an agate mortar for 30 minutes to make each component grind evenly to obtain a fiber core mixture and a cladding mixture respectively.

[0106] ...

Embodiment 2

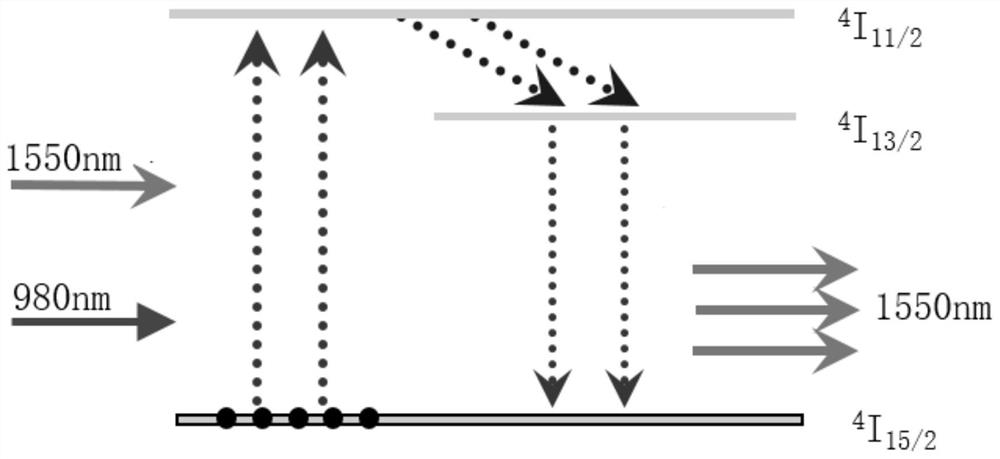

[0112] According to the Judd-Oflet theory, it is determined to obtain the stimulated emission cross section of the erbium-doped fiber involved in serial number 1, as attached Figure 7 As shown, the erbium-doped fiber involved in No. 1 has a larger stimulated emission cross-section, which indicates that the erbium-doped fiber involved in No. 1 can be used as a gain medium material for a broadband optical fiber amplifier. Based on this, the present embodiment 2 uses the 1m long erbium-doped optical fiber involved in the serial number 1 as the attached Figure 5 In the shown fiber amplifier, a 1480nm laser is used as a pumping source. When the pump power is 80mW and the signal light power is 1mW, the measured gain spectrum of the fiber amplifier covers 1545nm-1627nm (see Figure 8 ), which means that the gain spectrum of the fiber amplifier can cover the entire L-band (1565-1625nm) and part of the C-band (1530-1565nm), with a wider gain spectrum.

[0113] Based on the same test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com