Lead silicate glass used in double-clad optical fiber, and double-clad optical fiber preparation method

A technology of lead silicate glass and double-clad optical fiber, which is applied in the field of preparation of lead silicate glass for double-clad optical fiber and its double-clad optical fiber, and can solve glass tube polishing, reduce optical fiber pump coupling efficiency, and loss and other problems, to achieve the effect of shortening the preparation cycle, improving coupling efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

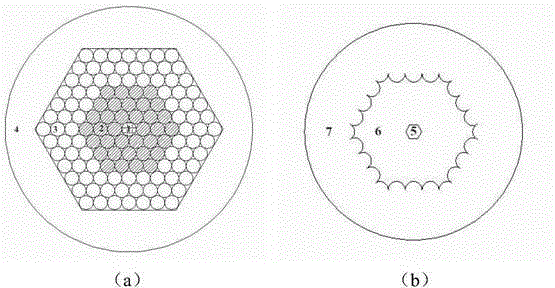

[0034] The preparation process of the lead silicate glass double-clad optical fiber of the present invention is as follows:

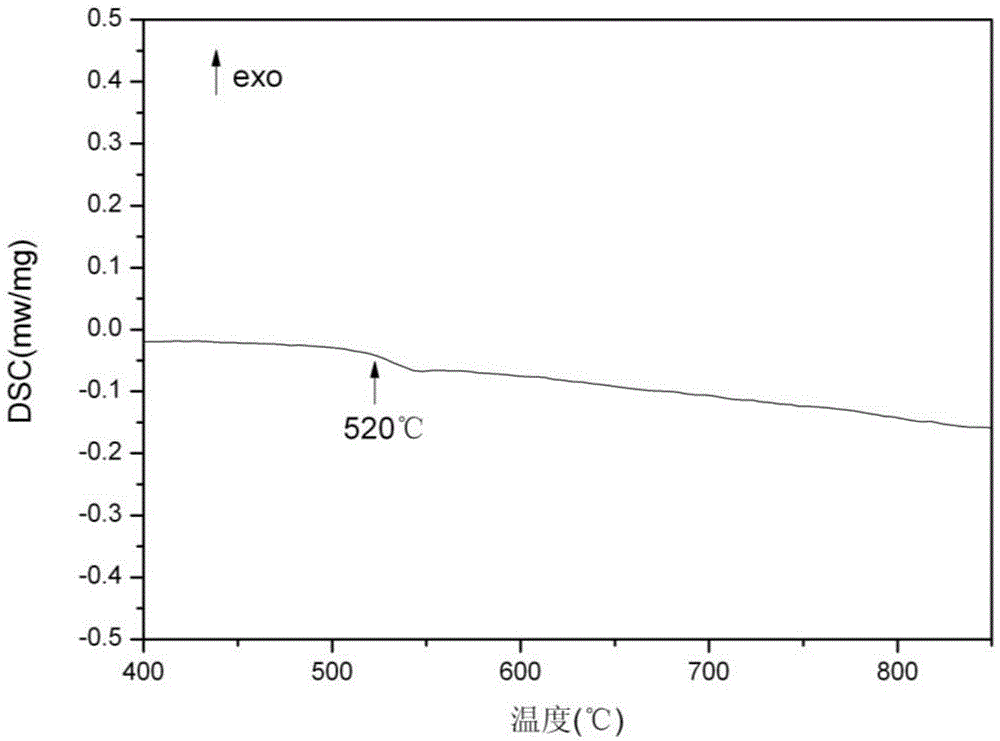

[0035] ① Preparation of core glass: Weigh the raw materials according to the formula of the core layer glass described in the invention, mix the powdery raw materials evenly, put them into a quartz ceramic crucible and melt them at a melting temperature of 1250-1350°C, and pass them into a pure Remove water by bubbling for 99.9% dry oxygen. After bubbling for two hours, clarify at 1450°C. After clarifying for half an hour, fully stir and homogenize. Send it into the annealing furnace, keep it warm for 20 hours within ten degrees above and below the glass transition temperature Tg, and then lower it to 100°C at 1-8°C / hour, then turn off the power of the annealing furnace, and naturally cool to room temperature;

[0036] ②Preparation of inner cladding glass: Except for different components, its preparation process is the same as that of core glass;

[00...

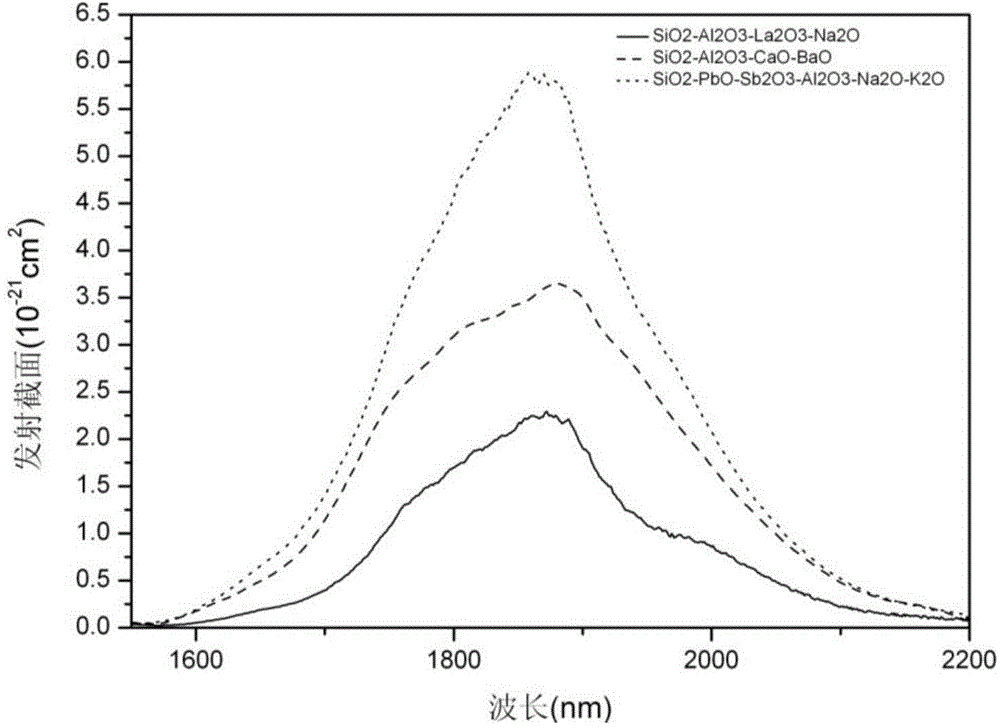

Embodiment 2

[0043] The composition of Example 2# is shown in Table 1, and the components were adjusted accordingly. The melting temperature was 1250°C, and the annealing rate was 1-8°C / hour down to 100°C. Prepare the optical fiber according to the steps ⑤-⑧ mentioned above.

Embodiment 3

[0044] The composition of Example 3# is shown in Table 1, and the components were adjusted accordingly. The melting temperature was 1300°C, and the annealing rate was 1-8°C / hour down to 100°C. Prepare the optical fiber according to the steps ⑤-⑧ mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com