Enrofloxacin injection and preparation method thereof

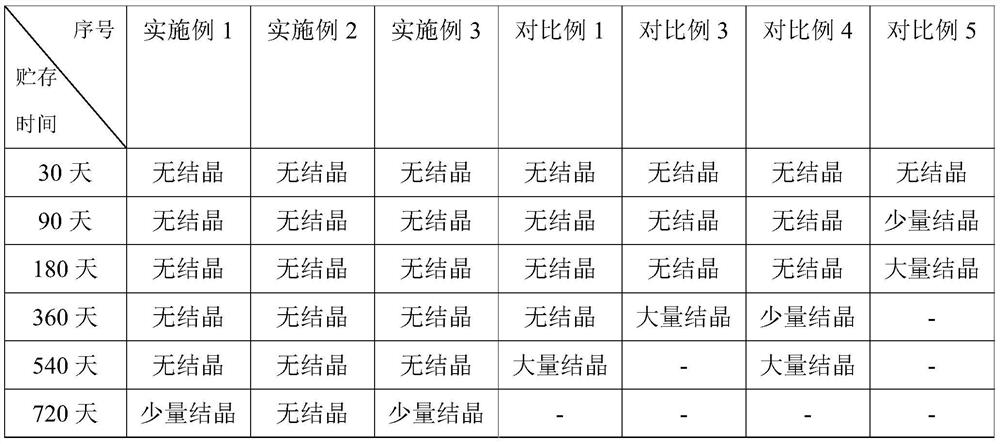

A technology of enrofloxacin and injection, which is applied in the direction of medical formula, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of easy crystallization, etc., and achieve simple operation and good stability , Improve the effect of insoluble problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Weigh 3 kg of enrofloxacin, 3.42 kg of cationized hydroxyethyl cellulose, 19.5 g of sodium alginate, 1.38 kg of nicotinamide, 0.39 kg of disodium edetate, 2.2 liters of propylene glycol, polyethylene glycol 7.8 liters, some water for injection; mix 2.2 liters of propylene glycol, 7.8 liters of polyethylene glycol, and 5 liters of water for injection to obtain a mixed solution.

[0026] 2. Add 3 kg of enrofloxacin, 19.5 g of sodium alginate, 1.38 kg of nicotinamide and 0.855 kg of cationized hydroxyethyl cellulose to the mixture, heat up to 52°C and stir evenly, keep the temperature and let it stand for 0.7 hours to get treatment liquid.

[0027] 3. First add 0.39 kg of disodium ethylenediamine tetraacetate to the treatment solution, raise the temperature to 72°C and stir it magnetically; 0.1MPa, keep magnetic stirring until enrofloxacin is completely dissolved to obtain a reaction solution.

[0028] 4. After cooling the reaction solution to room temperature at a ra...

Embodiment 2

[0030] 1. Weigh 1.8 kg of enrofloxacin, 2.052 kg of cationized hydroxyethyl cellulose, 11.7 g of sodium alginate, 0.828 kg of nicotinamide, 0.234 kg of disodium edetate, 1.8 liters of propylene glycol, polyethylene glycol 6.2 liters, some water for injection; mix 1.8 liters of propylene glycol, 6.2 liters of polyethylene glycol, and 8 liters of water for injection to obtain a mixed solution.

[0031] 2. Add 1.8 kg of enrofloxacin, 11.7 g of sodium alginate, 0.828 kg of nicotinamide and 0.513 kg of cationized hydroxyethyl cellulose to the mixture, raise the temperature to 52°C and stir evenly, and keep it at a constant temperature for 0.6 hours to get treatment liquid.

[0032] 3. First add 0.234 kg of disodium edetate to the treatment liquid, raise the temperature to 72°C and stir it magnetically; 0.1MPa, keep magnetic stirring until enrofloxacin is completely dissolved to obtain a reaction solution.

[0033] 4. After cooling the reaction solution to room temperature at a ra...

Embodiment 3

[0035] 1. Weigh 4 kg of enrofloxacin, 4.56 kg of cationized hydroxyethyl cellulose, 26 g of sodium alginate, 1.84 kg of nicotinamide, 0.52 kg of disodium edetate, 2.5 liters of propylene glycol, polyethylene glycol 8.2 liters, some water for injection; mix 2.5 liters of propylene glycol, 8.2 liters of polyethylene glycol, and 3.2 liters of water for injection to obtain a mixed solution.

[0036] 2. Add 4 kg of enrofloxacin, 26 g of sodium alginate, 1.84 kg of nicotinamide and 1.14 kg of cationized hydroxyethyl cellulose to the mixture, heat up to 52°C and stir evenly, and keep it at a constant temperature for 0.8 hours for processing liquid.

[0037] 3. Add 0.52 kg of disodium ethylenediamine tetraacetate to the treatment liquid, raise the temperature to 72°C and stir it magnetically; 0.1MPa, keep magnetic stirring until enrofloxacin is completely dissolved to obtain a reaction solution.

[0038] 4. After cooling the reaction solution to room temperature at a rate of 20°C / ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com