CO2 direct air trapping system and method based on wet regeneration adsorption material

An adsorption material, wet regeneration technology, applied in the field of DAC, can solve the problems of reduced purity, small storage capacity, solid powder pollution gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

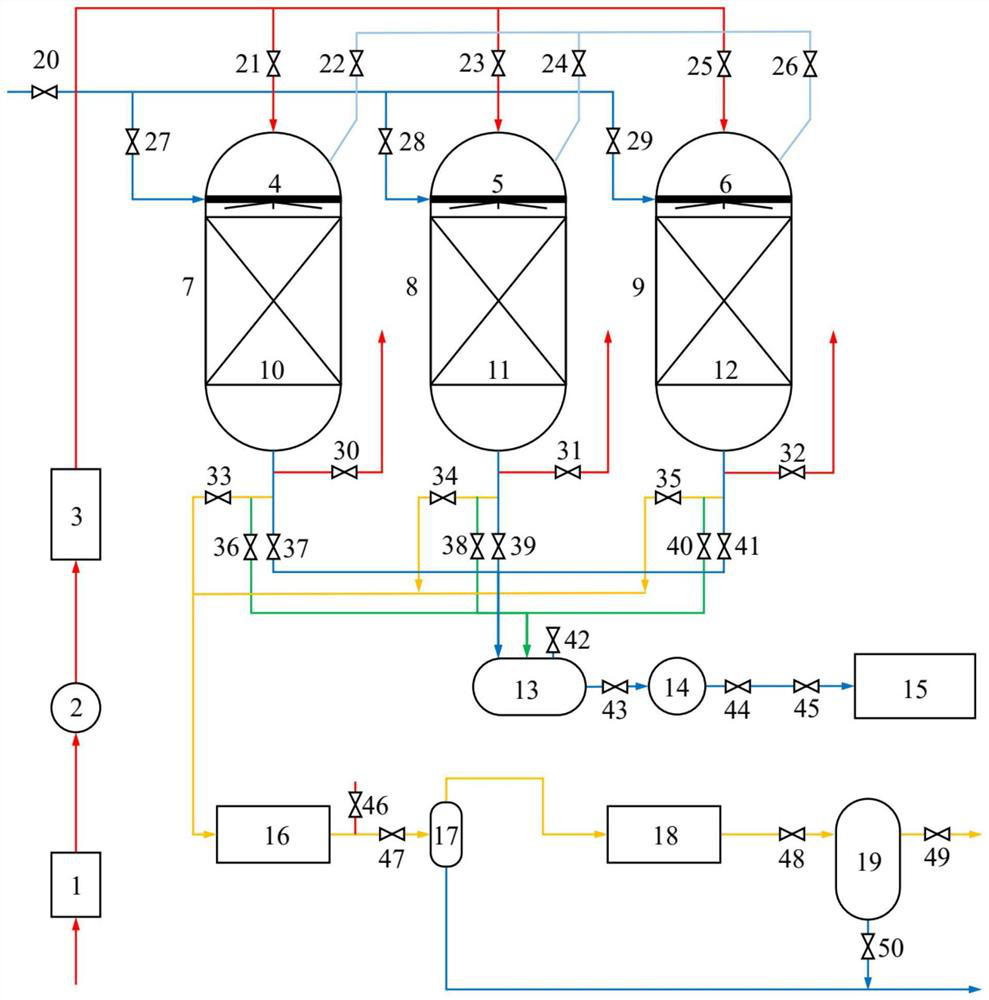

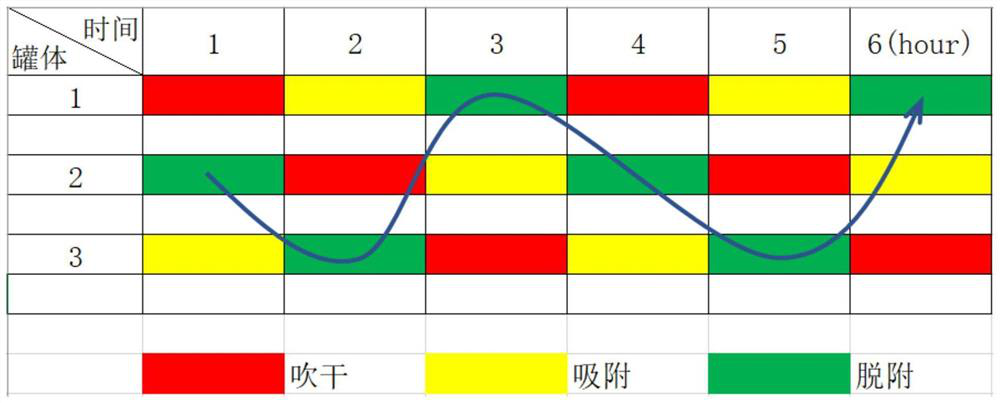

[0081] Using the CO based on the wet regeneration adsorption material described in the above technical scheme 2 Direct air capture system, the specific working process is as follows:

[0082] CO 2 Adsorbent material drying: Taking the first catch tank 7 as an example, the air in the environment (CO 2 Concentration is 0.04%) at 2300m 3 After the flow rate per hour is heated by the heat source 1 (40°C ~ 50°C), it is sent to the dehumidification device 3 by the fan 2, so that the relative humidity of the air is reduced to the range of 20% ~ 30%; the heated and dehumidified air passes through the valve 21 Enter the first catch tank 7, blow through the first group of CO from top to bottom 2 The adsorption material 10 thus plays a drying role, and then is discharged into the atmosphere through the valve 30; the whole drying process lasts for 1 hour.

[0083] CO 2 Adsorption: Group 1 CO 2 After the adsorption material 10 is dried for 1 hour, the heat source 1 can be turned off ...

Embodiment 2

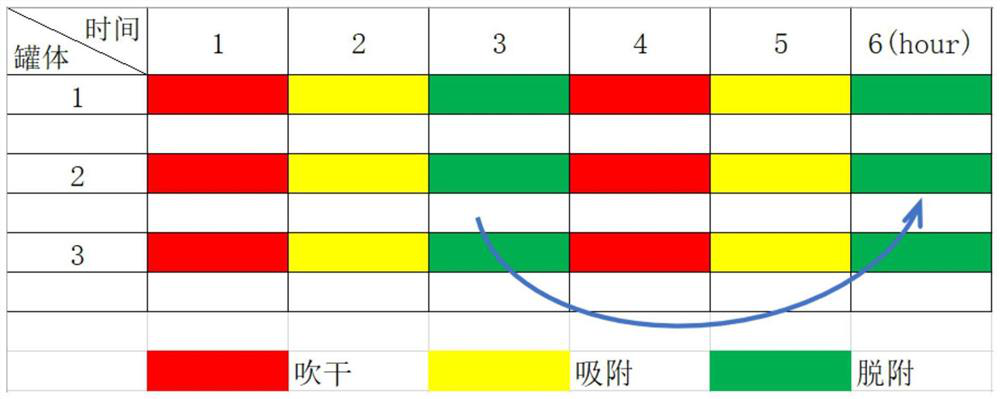

[0094] Using the CO based on the wet regeneration adsorption material described in the above technical scheme 2 Direct air capture system, the specific working process is as follows:

[0095] CO 2 Adsorbent material drying: vacuum drying is adopted, the initial stage is mainly to extract air, and the rest of the stage is to extract water vapor. Taking the first catch tank 7 as an example, the vacuum pump 16 first removes the air in the first catch tank 7 through the valve 33 and discharges it from the valve 46, so that the pressure in the tank drops below 2kPa (it should be noted that after vacuumizing While drying, the CO in the capture tank can be 2 The adsorption material is properly and continuously heated, so that the moisture inside the material diffuses into the low-pressure air on the surface through the pressure difference or concentration difference, and then is sucked away by the vacuum pump to further increase the drying speed); the subsequent process mainly remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com