MOF composite material adsorbent for removing benzene and preparation method thereof

A composite material and adsorbent technology, which is applied in the field of MOF composite adsorbent and its preparation, can solve the problems of poor adsorption effect, and achieve the effect of efficient adsorption effect, stable pore structure, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

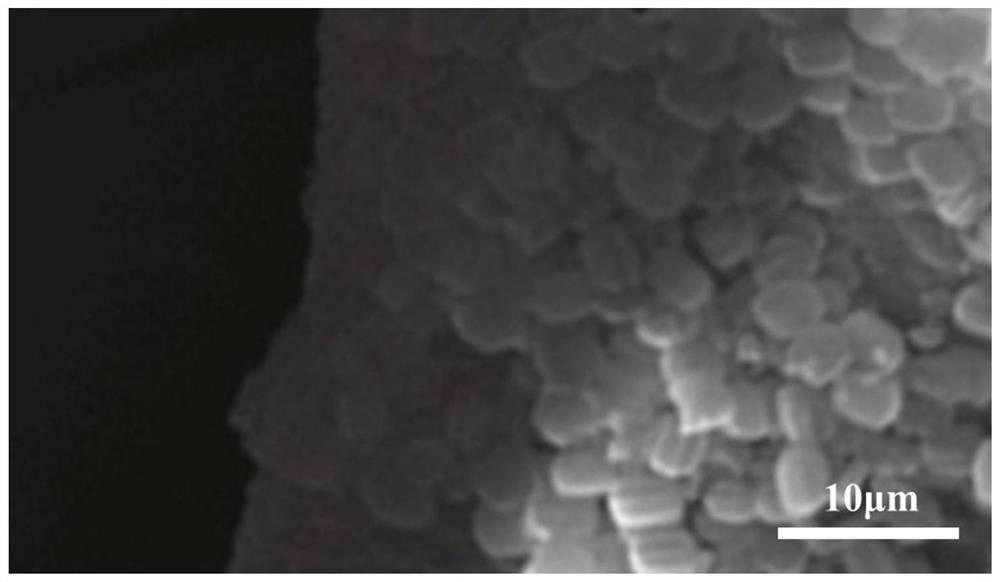

Image

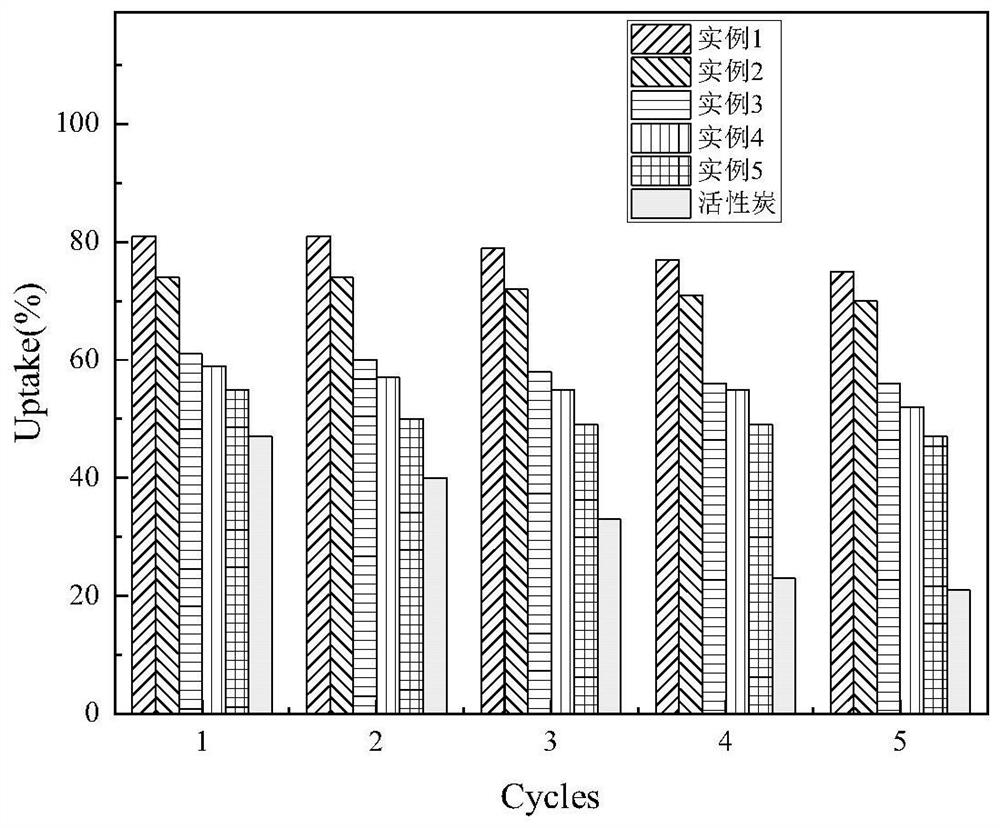

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of MOF composite material, comprises the following steps:

[0032] 1.1 Preparation method of MOF-199

[0033] a) 31.8g of Cu(NO 3 ) 2 ·3H 2 O and 13.8 g of trimesic acid (benzene 1,3,5 tricarboxylic acid) were dissolved in 200 mL of ethanol and placed in a 500 mL Erlenmeyer flask.

[0034] b) The solution was then heated to reflux, continuously stirred for 20 h, and then filtered to separate the blue precipitate, which was washed three times with ethanol.

[0035] c) drying under vacuum conditions at 120°C for 24 hours to obtain MOF-199.

[0036] 1.2 Preparation method of zeolite foam

[0037] a) Add 10 mL of 1.0 mol / L tetrapropylammonium hydroxide solution and 17 g of tetraethyl orthosilicate to 50 mL of deionized water.

[0038] b) Then, 3.2 mL of 1.0 mol / L sodium aluminate was added dropwise to the above solution, and stirred at room temperature for 2 h. The resulting translucent gel was transferred ...

example 2

[0046] The present embodiment provides a kind of preparation method of MOF composite material, comprises the following steps:

[0047] 1.1 Preparation method of MOF-199

[0048] a) 31.8g of Cu(NO 3 ) 2 ·3H 2 O and 13.8 g of trimesic acid (benzene 1,3,5 tricarboxylic acid) were dissolved in 200 mL of ethanol and placed in a 500 mL Erlenmeyer flask.

[0049] b) The solution was then heated to reflux, continuously stirred for 20 h, and then filtered to separate the blue precipitate, which was washed three times with ethanol.

[0050] c) drying under vacuum conditions at 120°C for 24 hours to obtain MOF-199.

[0051] 1.2 Preparation method of zeolite foam

[0052] a) Add 10 mL of 1.0 mol / L tetrapropylammonium hydroxide solution and 17 g of tetraethyl orthosilicate to 50 mL of deionized water.

[0053] b) Then, 3.2 mL of 1.0 mol / L sodium aluminate was added dropwise to the above solution, and stirred at room temperature for 2 h. The resulting translucent gel was transferred ...

example 3

[0061] The present embodiment provides a kind of preparation method of MOF composite material, comprises the following steps:

[0062] 1.1 Preparation method of MOF-199

[0063] a) 31.8g of Cu(NO 3 ) 2 ·3H 2 O and 13.8 g of trimesic acid (benzene 1,3,5 tricarboxylic acid) were dissolved in 200 mL of ethanol and placed in a 500 mL Erlenmeyer flask.

[0064] b) The solution was then heated to reflux, continuously stirred for 20 h, and then filtered to separate the blue precipitate, which was washed three times with ethanol.

[0065] c) drying under vacuum conditions at 120°C for 24 hours to obtain MOF-199.

[0066] 1.2 Preparation method of zeolite foam

[0067] a) Add 10 mL of 1.0 mol / L tetrapropylammonium hydroxide solution and 17 g of tetraethyl orthosilicate to 50 mL of deionized water.

[0068] b) Then, 3.2 mL of 1.0 mol / L sodium aluminate was added dropwise to the above solution, and stirred at room temperature for 2 h. The resulting translucent gel was transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com