Preparation and application of an inverse emulsion heavy metal ion imprinting material

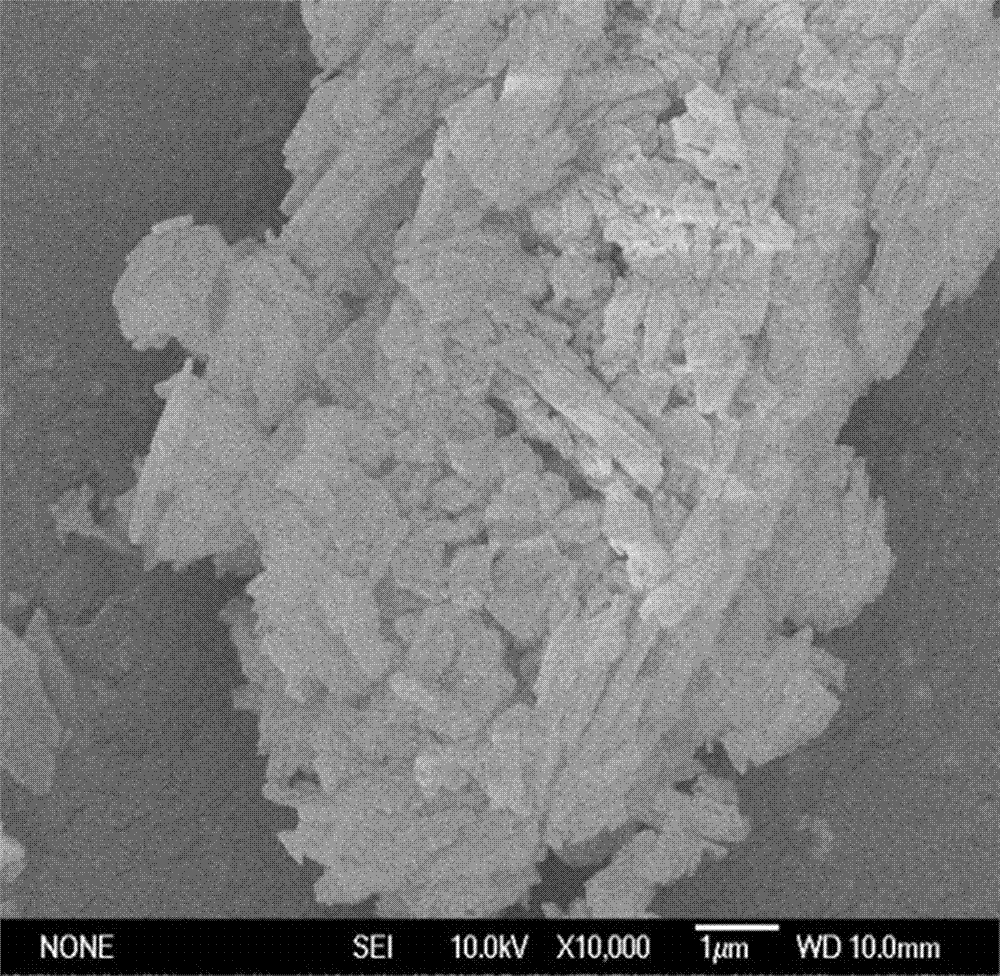

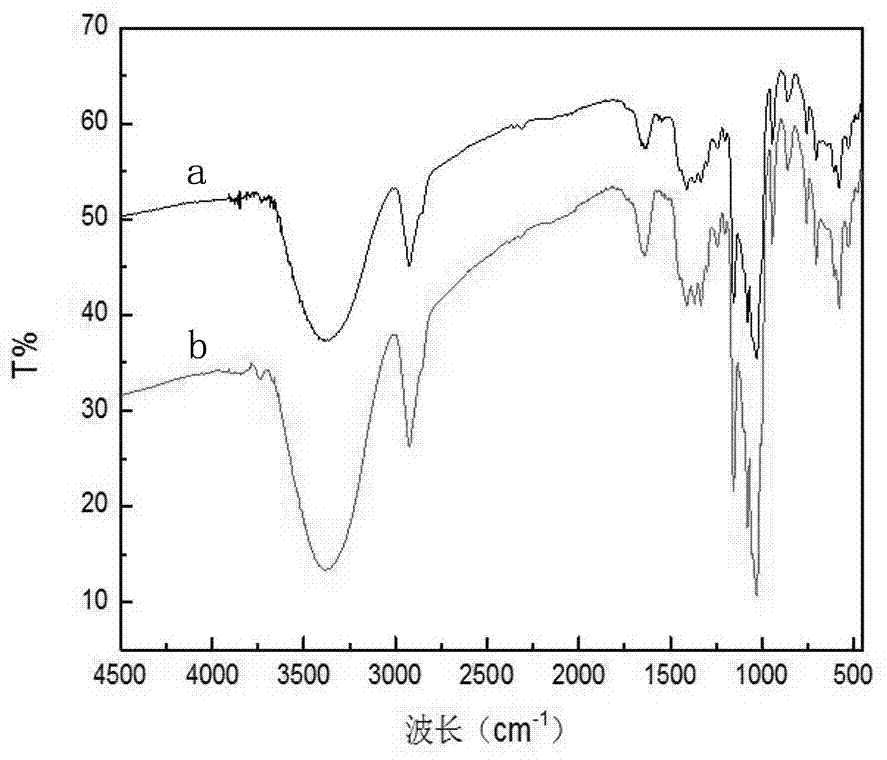

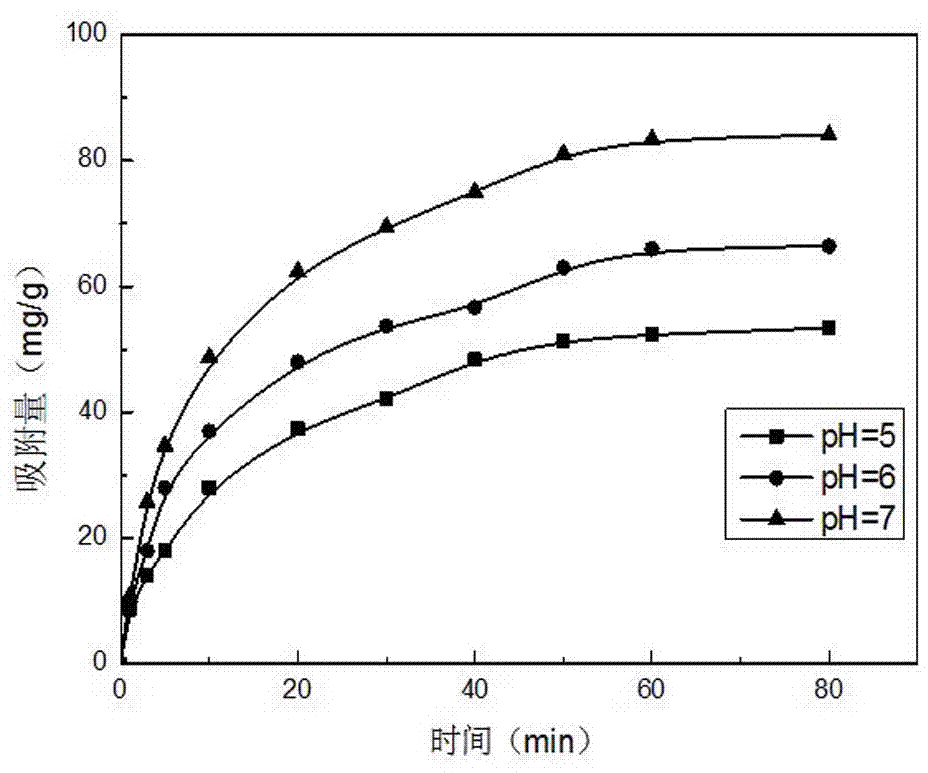

A technology of heavy metal ions and imprinted materials, applied in other chemical processes, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of less ion imprinted materials, easy layering, and difficult stability of inverse emulsions, etc., to achieve Strong specific adsorption capacity, small particle size, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 2mmol hydroxypropyl-β-cyclodextrin in double distilled water, add 20mmol N,N-dimethylacrylamide and 2mmol cadmium chloride aqueous solution, stir in water bath at 10°C for 60min;

[0028] Add 8g of Span20 and 1g of Tween20, then add 39g of gasoline, stir rapidly for 50min to form a water-in-oil inverse pre-emulsion;

[0029] Add 9 wt% of divinylbenzene in the total mass of the oil phase and the water phase and 0.5 wt% of ammonium persulfate in the total mass of the oil phase and the water phase, and react for 3 hours.

[0030] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0031] Add a mixed solution of methanol: acetic acid (9:1), shake at 40°C for 6 hours, and vacuum filter to obtain the precipitate;

[0032] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 6;

[0033] The washed polymer was placed in a vacuum drying oven, and dried at 70° C. for 8 hours to ob...

Embodiment 2

[0035] Dissolve 3mmol β-cyclodextrin in double distilled water, add 6mmol cadmium nitrate aqueous solution, add 40mmol methacrylamide aqueous solution, stir in water bath at 30°C for 40min;

[0036] Add 4.8g of Span60 and 1.2g of Tween20, then add 33.5g of kerosene, stir rapidly for 30min to form a water-in-oil inverse pre-emulsion;

[0037] Add ethylene glycol dimethacrylic acid of 5 wt% of the total mass of the oil phase and the water phase and azobisisobutyronitrile of 0.1 wt% of the total mass of the oil phase and the water phase, and react for 4 hours;

[0038] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0039] Add a mixed solution of methanol: acetic acid (9:1), shake at 30°C for 7 hours, and vacuum filter to obtain the precipitate;

[0040] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 7;

[0041] The washed polymer was placed in a vacuum drying oven, and dried at ...

Embodiment 3

[0043] Dissolve 4mmol γ-cyclodextrin in double distilled water, then add 30mmol N,N-dipropyl-2-methacrylamide and 10mmol cadmium sulfate aqueous solution, and stir at 60°C for 20min;

[0044]Add 5g of Span40 and 1g of Tween40, then add 36.4g of white oil, stir rapidly for 40min to form a water-in-oil inverse pre-emulsion;

[0045] Add 7wt% N,N-methylenebisacrylamide of the total mass of the oil phase and the water phase and 0.3wt% dimethyl azobisisobutyrate of the total mass of the oil phase and the water phase, and react for 5 hours;

[0046] The obtained emulsion is demulsified with ethanol and acetone to obtain polymer microspheres;

[0047] Add a mixed solution of methanol: acetic acid (9:1), shake at 50°C for 5 hours, and vacuum filter to obtain the precipitate;

[0048] The precipitate was repeatedly washed with double distilled water until the pH of the filtrate was 6;

[0049] The washed polymer was placed in a vacuum drying oven, and dried at 50° C. for 24 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com