Water cooling module for Tokamak device adopting stainless steel-copper alloy composite plate and processing method of water cooling module

A tokamak and stainless steel technology, which is applied in the field of water-cooled modules of tokamak devices, can solve the problems that the heat on the graphite surface cannot be discharged in time, the heat dissipation area of the cylindrical flow channel is small, and cannot meet the application requirements, etc., and achieve excellent heat removal capacity , Mature welding technology and welding processability, the effect of small thermal stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

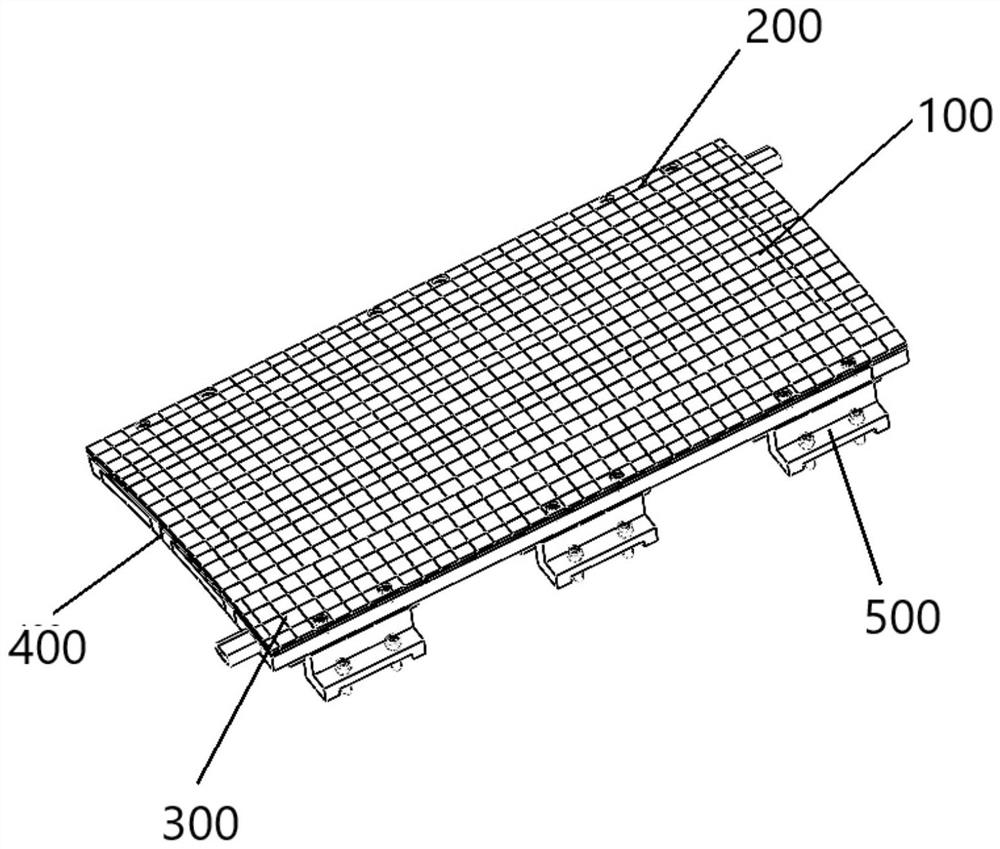

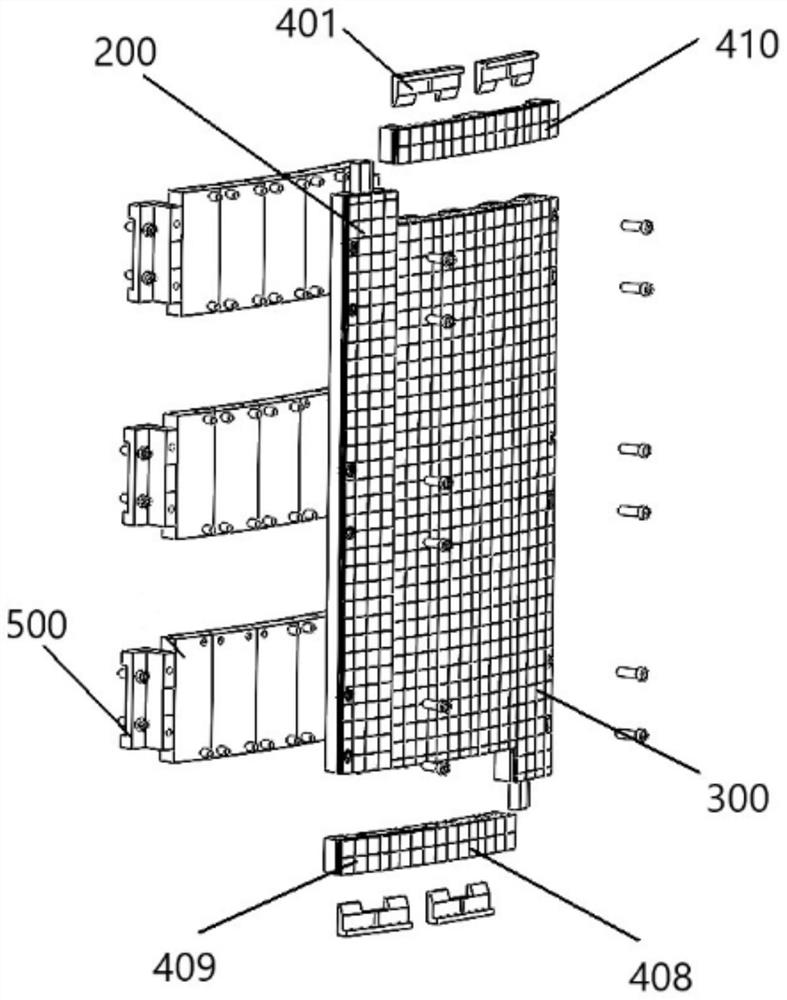

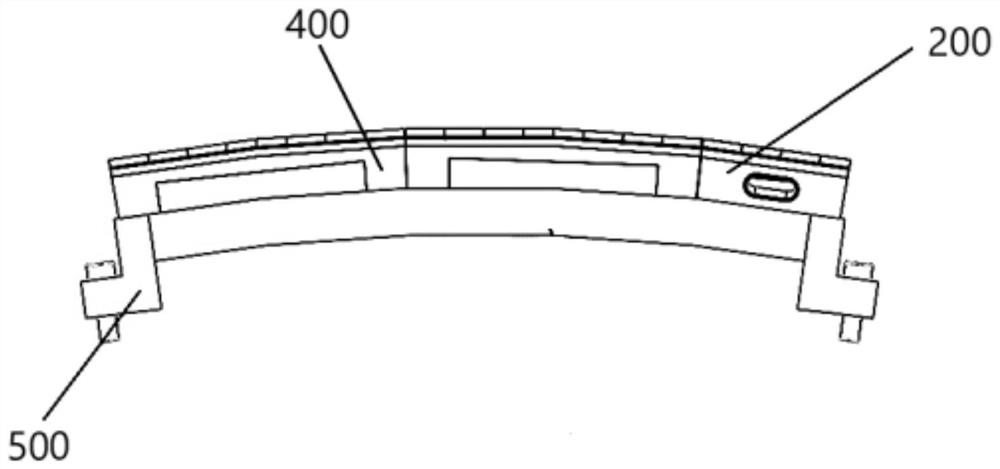

[0059] Such as Figure 1-Figure 3 The shown water cooling module of a tokamak device using stainless steel copper alloy composite plate includes a water cooling unit 100 and a water inlet unit 200 and a water outlet unit 300 respectively arranged on the left and right sides of the water cooling unit 100 . The upper and lower sides of the water cooling unit 100 are respectively provided with coupling units 400 . The water cooling unit 100, the water inlet unit 200, the water outlet unit 300, and the coupling unit 400 are connected to form a rectangular plate-shaped high-field first wall unit, and the shape of the front and back of the high-field first wall unit is consistent with that of the high-field side vacuum wall. The shape fits. Preferably, the wall profile of the high-field first wall unit facing the vacuum chamber is polygonal, which is compatible with the cylindr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap