Method and device for detecting alkane content in natural gas

A detection method and technology of natural gas, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of complex equipment and instrument requirements, long analysis cycle, etc., and achieve the effect of fast detection speed, high accuracy and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

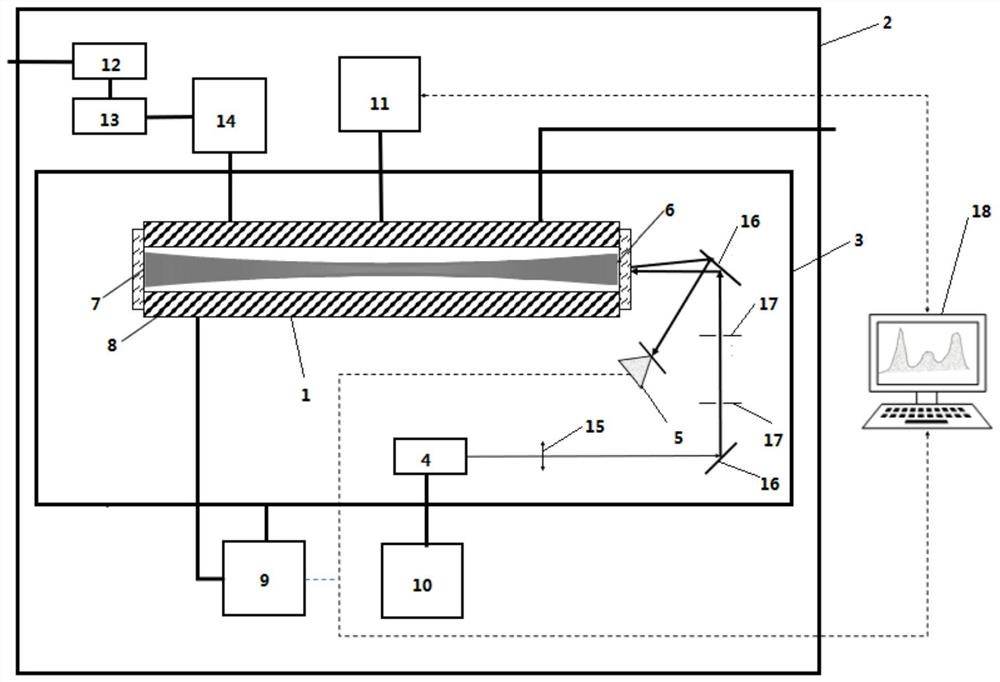

[0054] This embodiment provides a detection device for methane, ethane and propane content in natural gas, the structure is as follows figure 1 As shown, it includes an outer shell 2 and an inner shell 3 , and the inner shell 3 is provided with an optical cavity 1 , a laser 4 and a detector 5 . Both ends of the optical cavity 1 are equipped with a first Heriott reflector 6 and a second Heriott reflector 7, wherein the first Heriott reflector 6 has a central hole, and the laser 4 emits The laser light enters the optical cavity 1 through the central hole of the first Heriott mirror 6 through the lens 15 , two mirrors 16 and two groups of diaphragms 17 , and the outgoing light signal is received by the detector 5 .

[0055] The surface of the optical cavity 1 is covered with a heating insulation layer 8, and the temperature control module 9 arranged in the outer casing 2 heats the heating insulation layer 8 and the inner casing 3, and a laser driver 10 connected to the laser 4 is...

Embodiment 2

[0059] In this embodiment, the detection device in Embodiment 1 is used to detect the content of methane, ethane, propane, butane and pentane in the natural gas to be tested. Specific steps are as follows:

[0060] (1) Turn on the air pump and the heating preprocessor, the temperature control module heats the heating insulation layer of the cavity and the inner shell 19 to 50°C and 30°C respectively, and the laser part modulates the current of the laser through an external function generator, A triangular wave with a scanning frequency of 7Hz is used to modulate the driving current of the laser, so that the frequency of the laser output laser linearly scans CH 4 at the first wavelength v 1 The wavenumber of the laser is 6060.5cm -1 Near the transition line, that is, the wavelength is 1.65 μm;

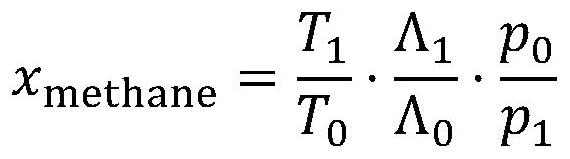

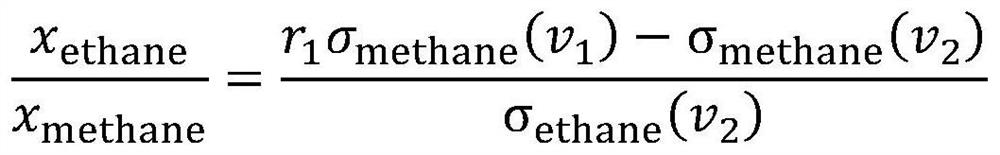

[0061] (2) the pure CH 4 Pass a certain flow into the optical cavity, record the temperature in the experiment as 50°C and the pressure as 50torr, and measure the value of light ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com