Surface treatment method of fiber-based photovoltaic backboard and aging-resistant chemical fiber-based photovoltaic backboard

A photovoltaic backplane and surface treatment technology, which is used in special surfaces, photovoltaic power generation, pretreated surfaces, etc., to achieve the effect of facilitating curing and molding, improving composite functions, and improving adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

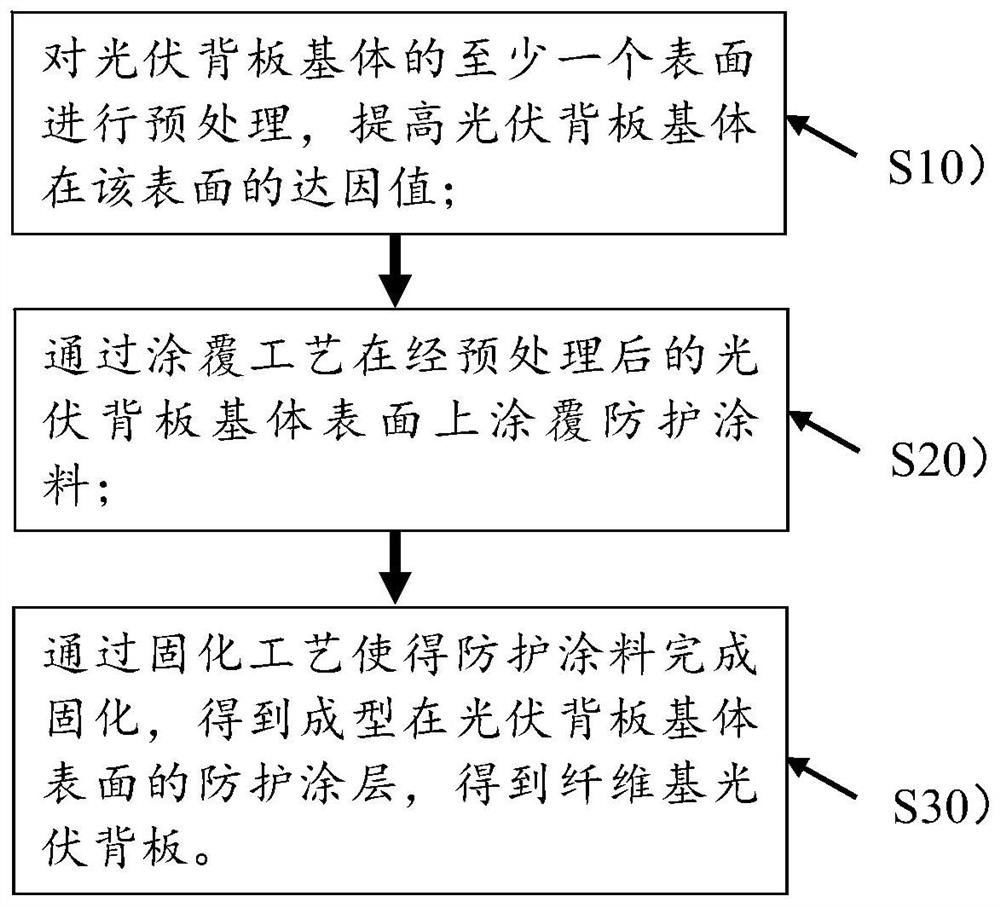

Method used

Image

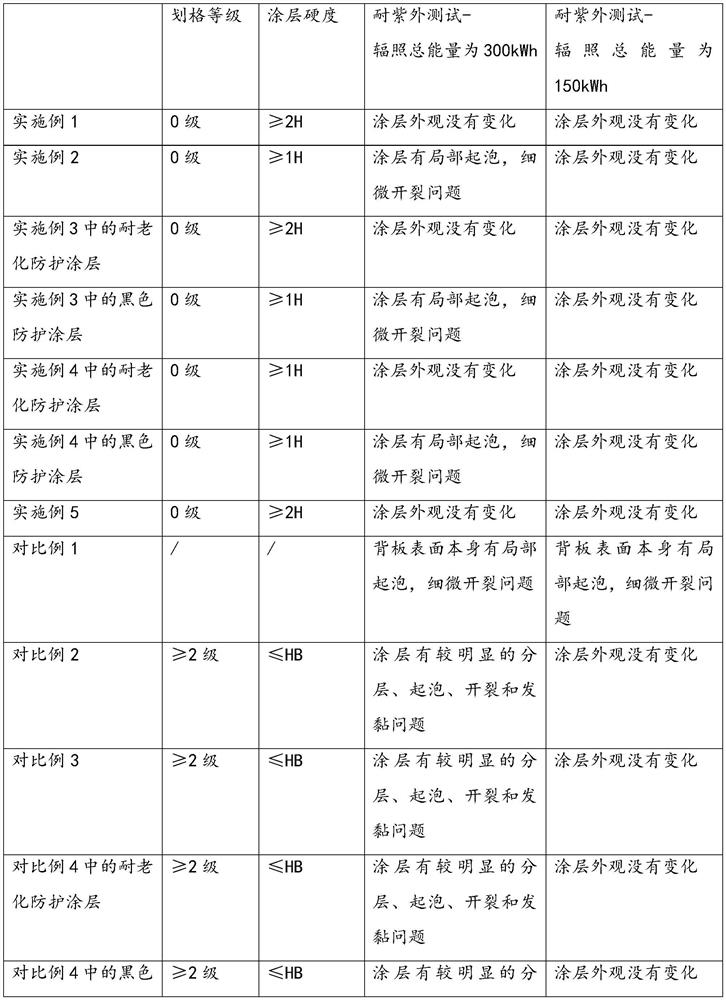

Examples

Embodiment 1

[0038] Example 1: An aging-resistant fiber-based photovoltaic backplane, using the encapsulation material provided by CN201610685240.9 as a photovoltaic backplane matrix based on composite molding of fiber materials, with a thickness of 3mm; through a corona machine (working power set at 6KW) to the photovoltaic Corona treatment is carried out on one surface of the backplane substrate, and the dyne value of the corona-treated photovoltaic backplane substrate on this surface reaches 52 dyn / cm after detection by a dyne pen; Coating liquid fluorine-containing coatings, wherein the weight ratio of fluorocarbon resin, curing agent, and organic solvent in the liquid fluorine-containing coatings is 22:1:8; the coated photovoltaic backplane substrate is coated in a tunnel furnace Implement a pre-curing step (pre-curing temperature is 165°C, pre-curing time is 2.5 minutes), and then transfer to a drying room for a complete curing step (curing temperature is 55°C, curing time is 50 hours...

Embodiment 2

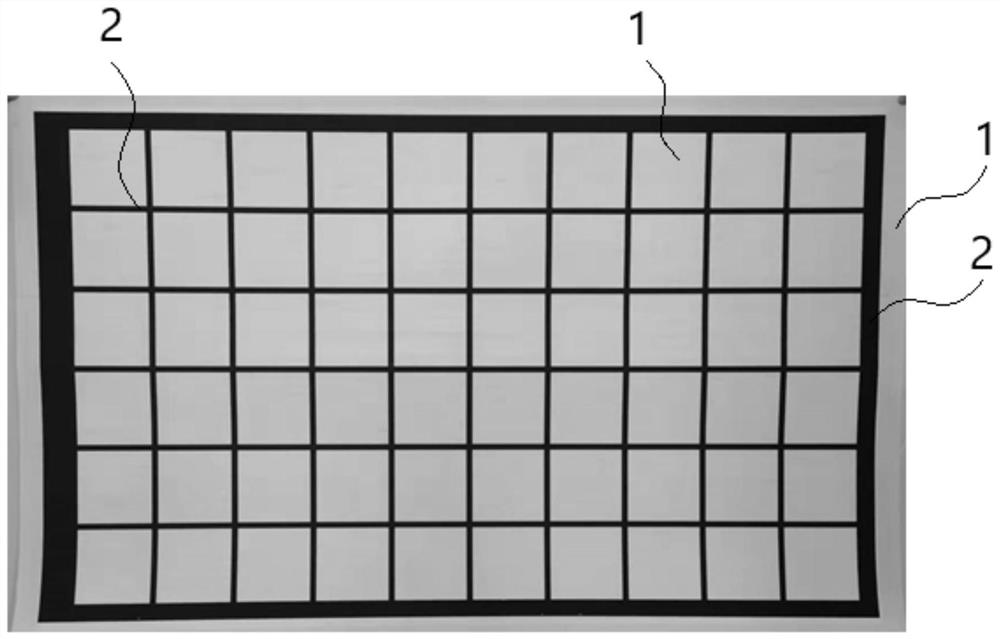

[0039] Embodiment 2: the remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that in this embodiment 2, the liquid fluorine-containing paint in embodiment 1 is replaced by a liquid black paint, wherein the acrylic acid in the liquid black paint The weight ratio between resin, curing agent, carbon black and organic solvent is 22:1:10:6. The black protective coating is grid-like. After testing, the thickness of the black protective coating is 15 microns; of course The thermosetting resin in the liquid black paint can also be fluorocarbon resin or other known thermosetting resins, which are not specifically and uniquely limited in this embodiment.

Embodiment 3

[0040] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the difference is that please refer to figure 2 As shown, on the basis of the aging-resistant fiber-based photovoltaic backsheet obtained in Example 1, corona treatment is carried out on the other side by a corona machine (working power is set at 5KW), and it is detected by a dyne pen to confirm that after corona treatment The dyne value of the photovoltaic backplane substrate on the surface reaches 50dyn / cm; the liquid black paint is coated on the surface by a screen printing machine, wherein the liquid black paint contains acrylic resin, curing agent, black organic dye, organic solvent The proportion by weight between them is 20:1:1:20; in the tunnel furnace, implement the pre-curing step (the pre-curing temperature is 170 ° C, and the pre-curing time is 1.5 minutes) to the photovoltaic backplane substrate that has been coated, and then Transfer to a drying roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com