Method for efficiently recovering iron and phosphorus resources in phosphorus-containing steel slag

A phosphorus resource and steel slag technology, applied in the field of metallurgical resource recycling, can solve the problems of low utilization value of phosphorus resources, failure to realize the recovery and efficient utilization of iron and phosphorus in steel slag, and low phosphorus concentration, so as to promote resource utilization and reduce implementation costs. Inexpensive, high recycling accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

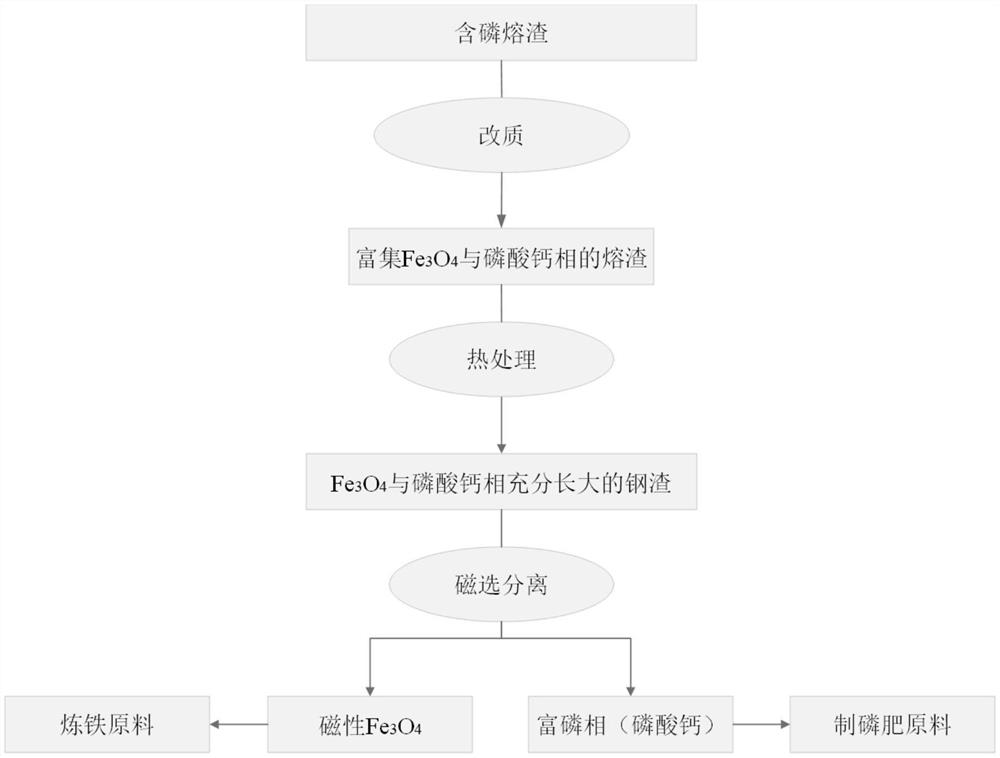

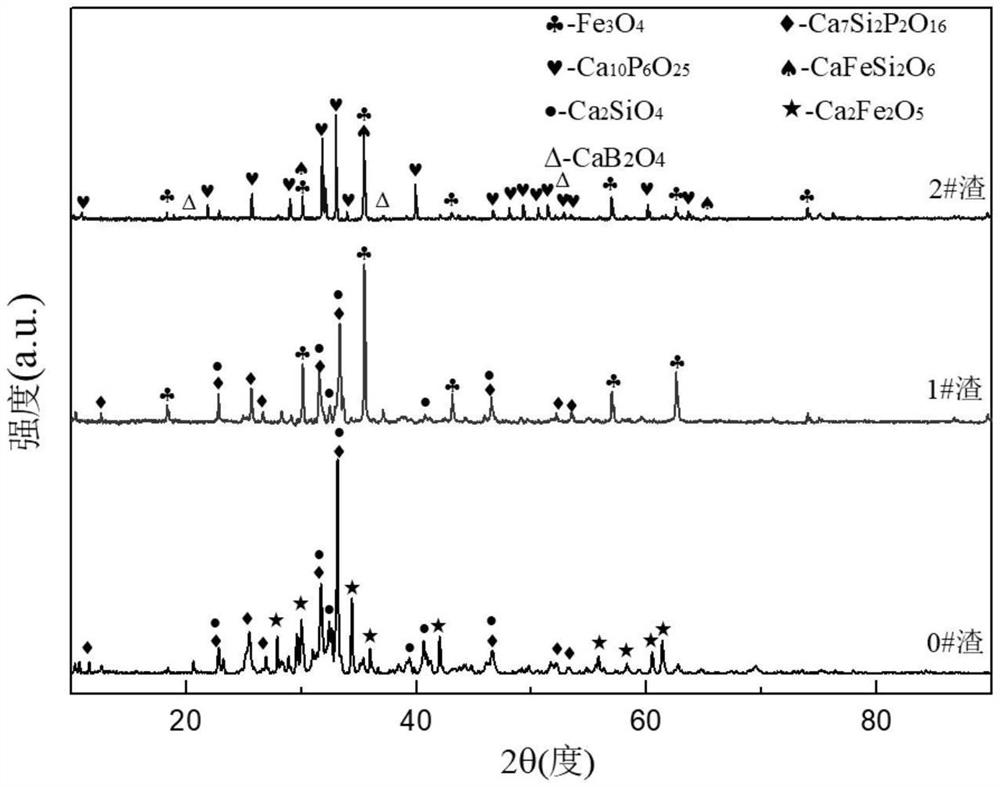

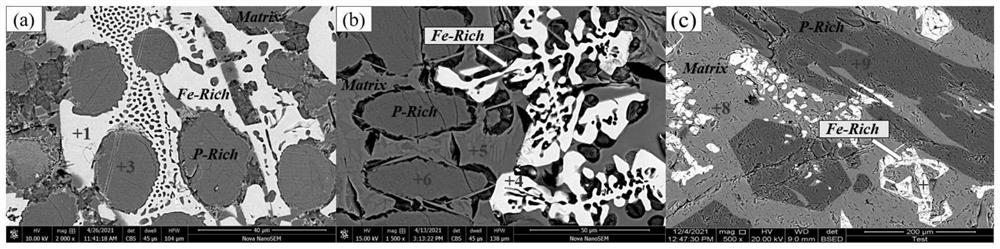

[0036] figure 1 Flow chart of the method for efficiently recovering iron and phosphorus resources in phosphorus-containing steel slag, according to figure 1 The process shown is to separate and recover iron and phosphorus resources from the five-element slag, where the composition of the five-element slag includes CaO, SiO 2 , FeO, P 2 o 5 , B 2 o 3, the sample obtained by sintering the five-element slag sample under air atmosphere is recorded as 0# slag, and the oxygen partial pressure is changed to 10-6 atm to obtain 1# sample, and on this basis, 6% B2O3 is added to the slag to obtain 2 # slag, the specific composition is as shown in Table 1.

[0037] Table 1. Composition of five-element simulated slag (wt.%)

[0038] CaO SiO 2

FeO P 2 o 5

B 2 o 3

1# 38.57 15.43 36 10 0 2# 34.29 13.71 36 10 6

[0039] The specific steps are as follows:

[0040] (1) will B 2 o 3 Mix it with phosphorus-containing simulated sla...

Embodiment 2

[0060] Based on the composition of steel slag in a certain factory, while changing the partial pressure of oxygen, adding SiO to the simulated slag 2 Obtain modified slag 1# (in slag), or add SiO to slag 2 with B 2 o 3 Get 2# slag, continue to add B 2 o 3 Get 3# slag. The composition of the modified slag is shown in Table 4.

[0061] Table 4. Simulated slag composition (wt%)

[0062] CaO SiO 2

FeO P 2 o 5

B 2 o 3

1# 30 24 36 10 0 2# 28.33 22.67 36 10 3 3# 27.22 21.78 36 10 5

[0063] The test steps are as follows:

[0064] (1) will B 2 o 3 Mix it with phosphorus-containing simulated slag, put it into a platinum crucible, and put it into a VTL-1700 tube furnace. The modifier content ranges from 6% to 8%;

[0065] (2) Pour argon into the furnace to control the partial pressure of oxygen to be less than 10 -4 atm. Control the temperature of the tube furnace to 1550°C and hold it for half an hour to ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com