Collector plate structure of circular lithium ion battery and welding method

A lithium-ion battery, collector plate technology, applied in welding equipment, non-electric welding equipment, laser welding equipment and other directions, can solve the problems of lack of internal self-protection ability of the battery, poor anti-vibration performance, etc., to increase anti-vibration performance, repeat The effect of good performance and simple welding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A structure and a method for cutting tabs of a novel circular lithium-ion battery pole piece, the steps of which are as follows:

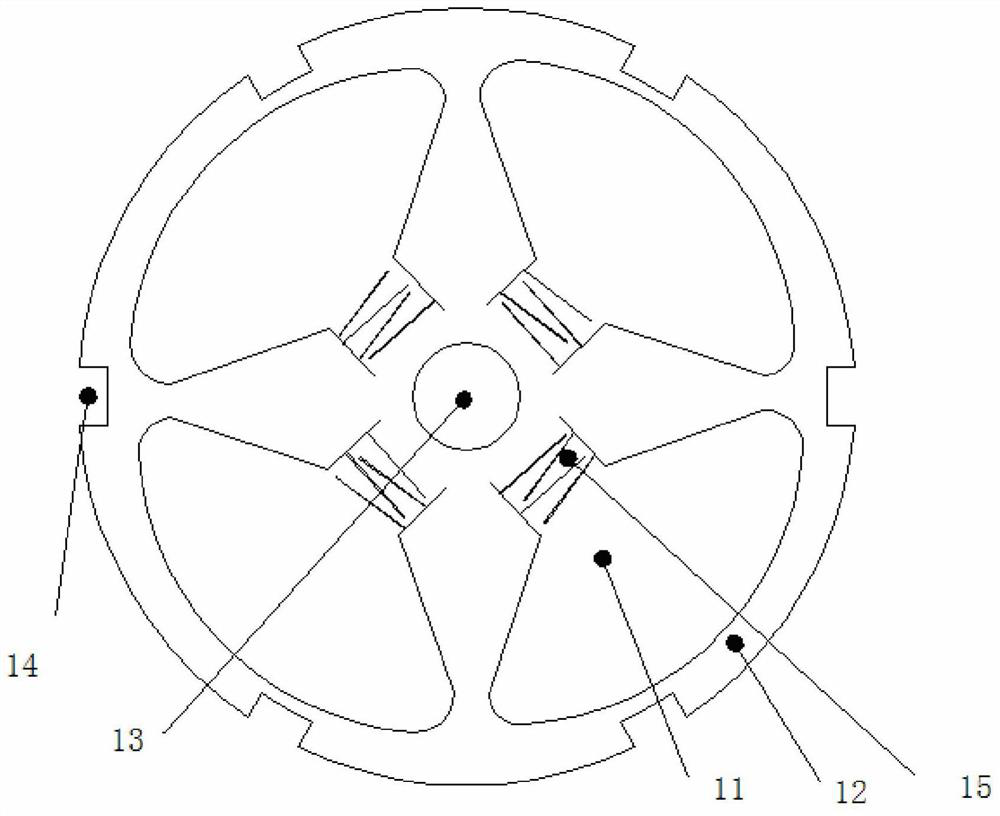

[0032] The circular diameter of the negative current collector plate of the designed circular battery is 37mm, the notch width of the positioning groove of the outer ring is 1.34mm, the height is 2.79mm, the diameter of the central hole is 5.11mm, the radius of the sector area is 13mm, and the angle is 90°. There are four sectors in total. Reserve a certain area at the fan-shaped root to cut two vertical lines, and cut some folded lines with rounded corners inside the vertical lines for force buffering (such as figure 1 The top view of the structure of the negative electrode current collecting plate, in the figure: the welding area 11 between the negative electrode flattening layer and the negative electrode current collecting plate, the welding area 12 between the negative electrode current collecting plate and the shell, the central hole 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com