High-speed white spirit full-automatic filling and packaging process

A packaging process, fully automatic technology, applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of large footprint, weak automation configuration, low integration, etc., to facilitate stacking and improve site space The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

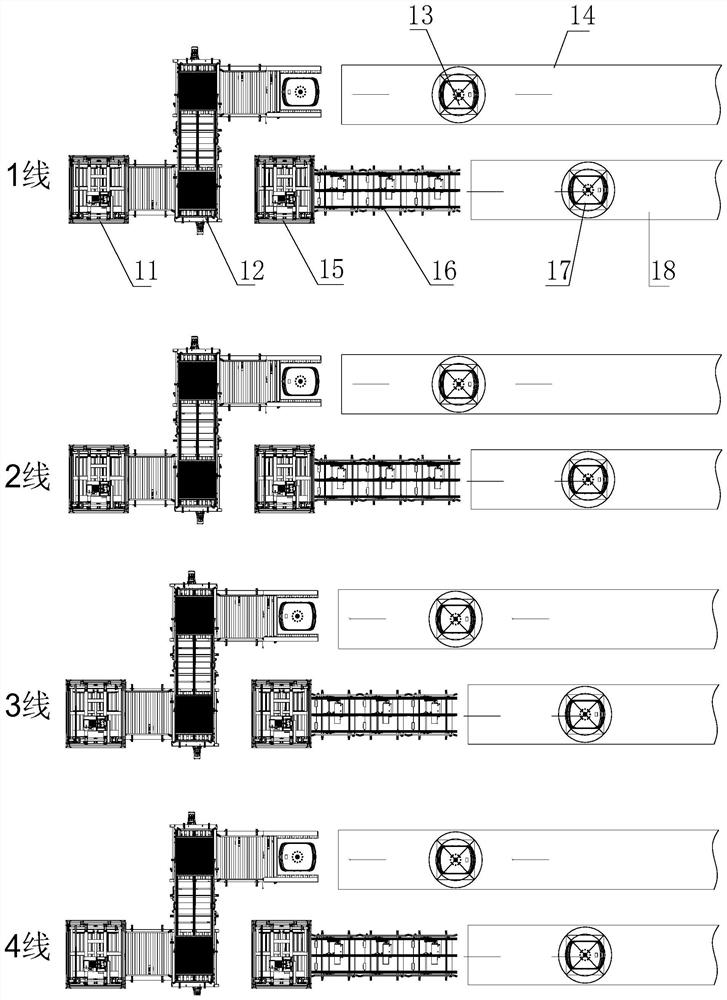

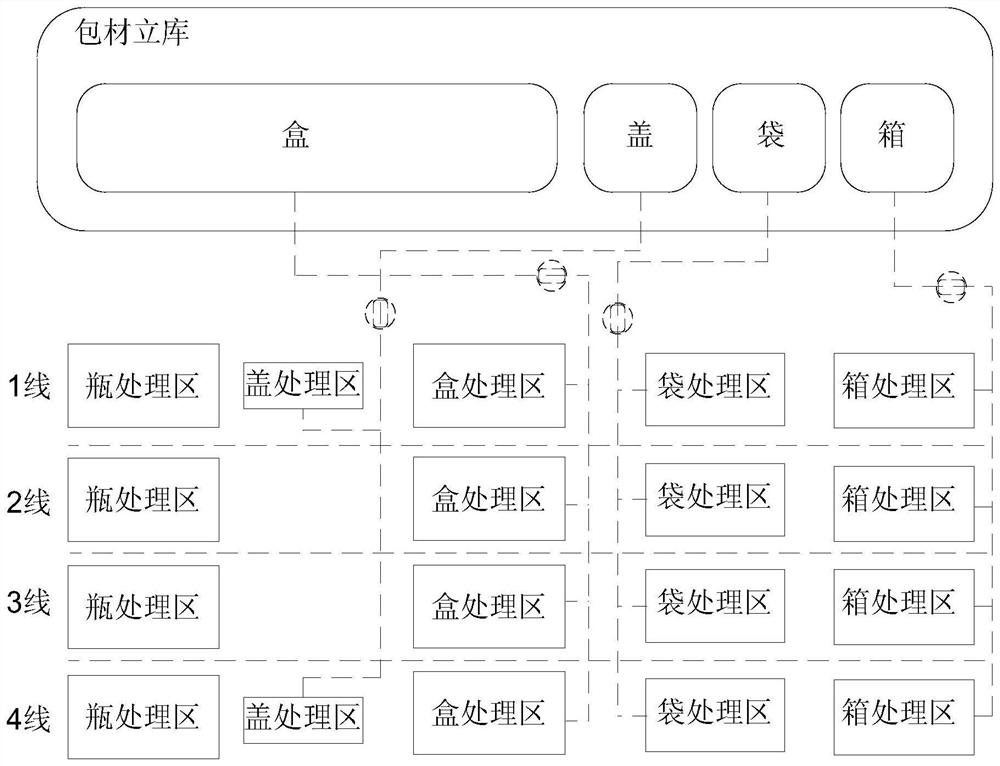

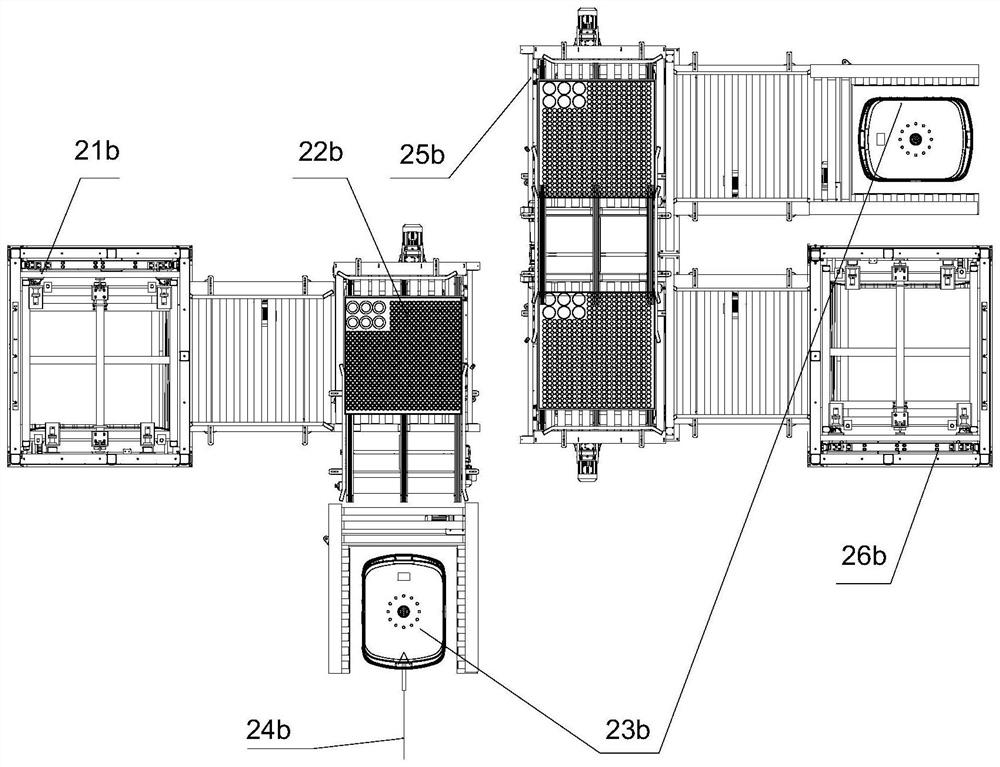

[0079] A high-speed automatic filling and packaging process for liquor proposed by the present invention uses a three-story workshop building as a system carrier to realize the process, and distributes equipment and assembly lines on three floors of the factory building, wherein: the first floor is used as an automatic bottle warehouse , Rely on AGV to transport the bottle stack, and lift the bottle stack to the second floor by the hoist. The second floor is used as a packaging material processing area, and the three-dimensional warehouse for packaging materials is set up on the second floor, where the depalletizing, conveying and lifting of packaging materials including bottles, caps, boxes, boxes and handbags is realized. From the first floor to the second floor, there are 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap