Composite metal sulfide with broad-spectrum bactericidal performance and preparation thereof

A composite metal and sulfide technology, applied in the direction of bactericide, iron sulfide, biocide, etc., can solve the problems that cannot be applied in anaerobic environment, and achieve the effect of preventing microbial corrosion, low bactericidal concentration, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 10mmol sodium molybdate, 10mmol ferric chloride, 5mmol 4,4-bipyridine and 60mL ultrapure water to the beaker, stir magnetically for 30min, transfer to a 100mL hydrothermal reactor, and crystallize at 120°C for 10h. After the crystallization, cool down to room temperature naturally, take out the precursor, and first wash with ultrapure water for 3 times; the centrifugation condition is 4000 rpm, centrifuge for 10 min, and dry at 60°C after washing to obtain the precursor, which is ready for use.

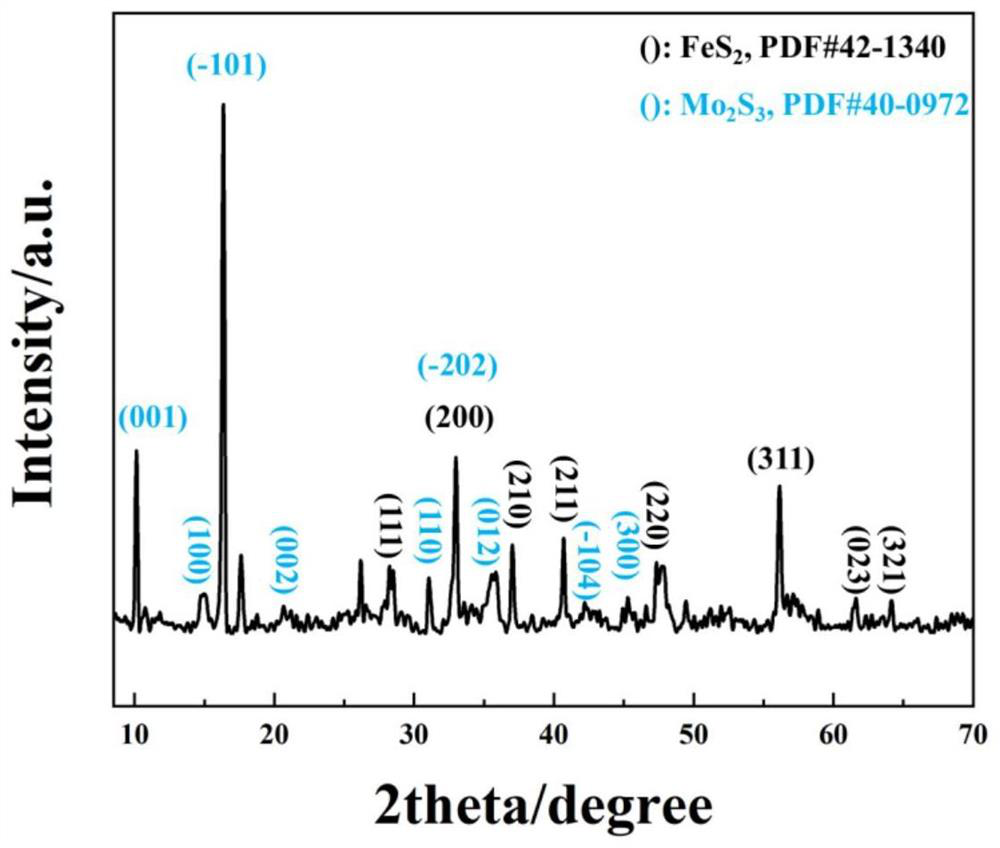

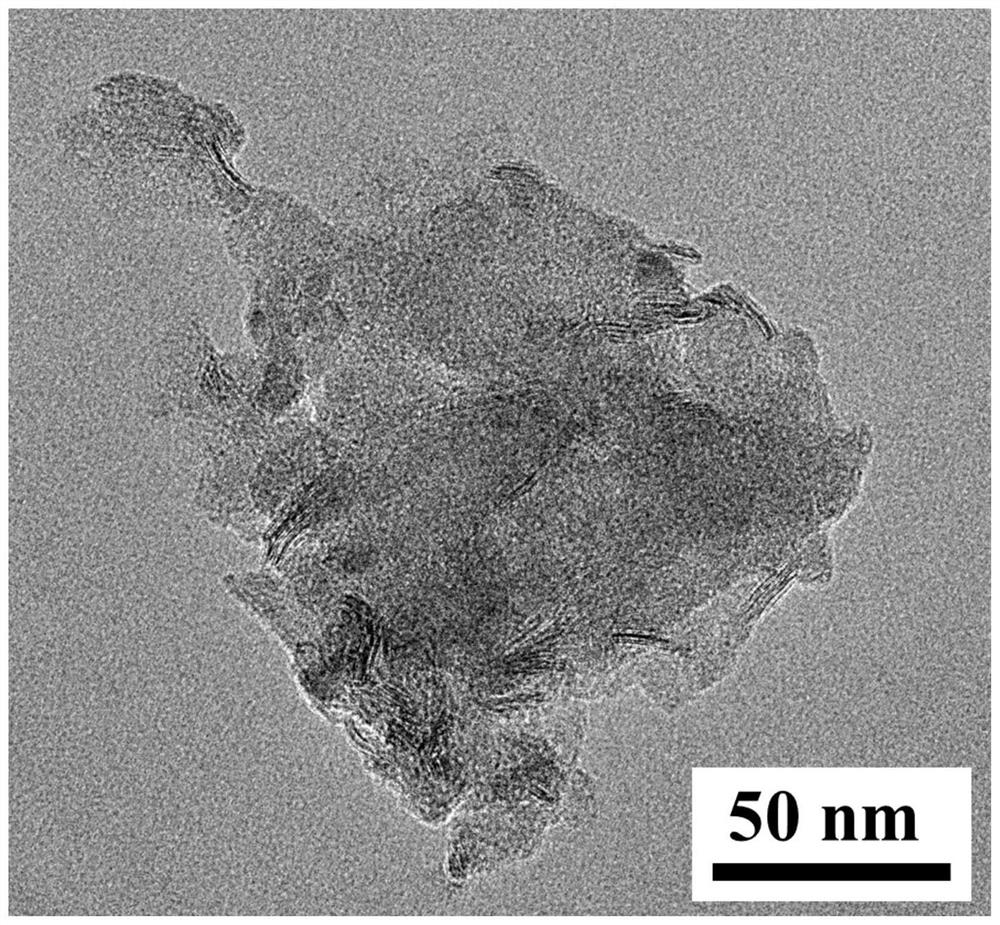

[0028] Add 0.5g precursor, 1.0g thioacetamide, and 60mL ultrapure water to the beaker, stir magnetically for 30min, disperse evenly, transfer to a 100mL hydrothermal reactor, and vulcanize at different temperatures for 14h (see Table 1). After the reaction finished, the reactor was naturally cooled to room temperature, cleaned and dried according to the above-mentioned steps, and obtained composite metal sulfide (see figure 1 ).

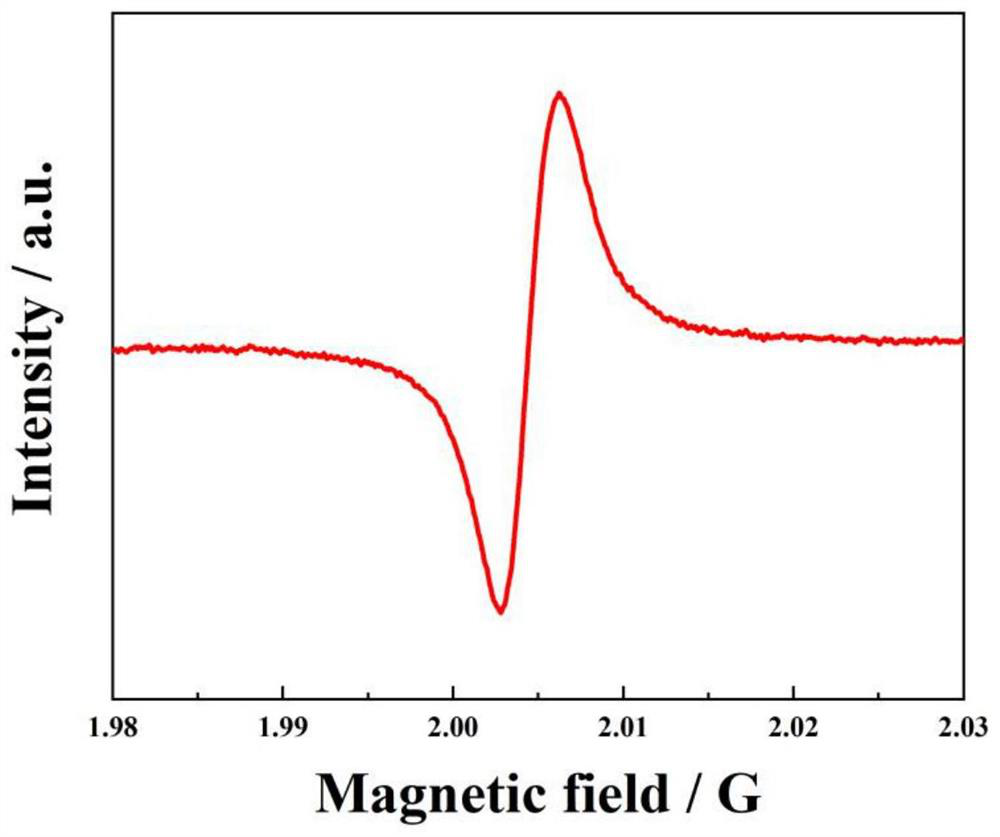

[0029] Depend on figure 1 In order to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com