Method and device for separating, refining and purifying intermediate m-xylylene dicarbamate solution and application of intermediate m-xylylene dicarbamate solution

A technology of ethyl isoxylylene dicarbamate and solution, which is applied in the field of separation, purification and purification of ethyl isoxylylene dicarbamate solution of an intermediate, and can solve the problems of unmentioned methods of separation and purification, Influence and other problems, to achieve the effect of efficient recycling and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

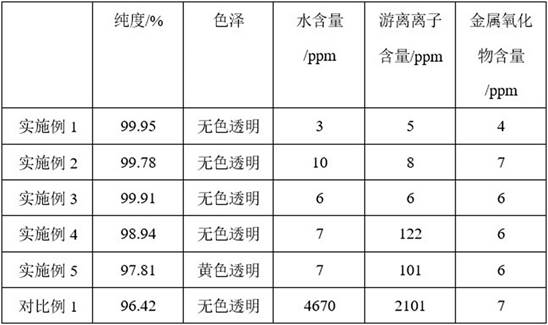

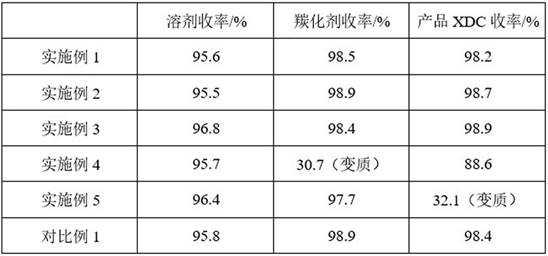

Embodiment 1

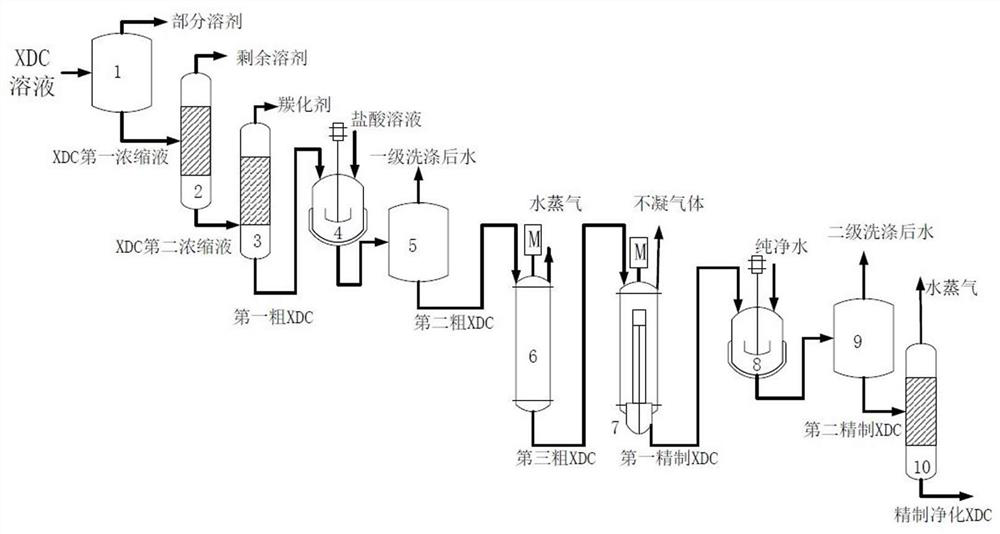

[0055] This embodiment provides a method for the separation, purification and purification of the intermediate m-xylylenedicarbamate solution, and the schematic flow chart of the method is as follows figure 1 As shown, the method includes the following steps:

[0056] Provide XDC solution synthesized under high temperature and high pressure (3.2MPa, 200°C), the main components in the XDC solution include intermediate m-xylylene dicarbamate, solvent ethanol, carbonylating agent ethyl carbamate And trace impurities and by-products.

[0057] (1) Send the XDC solution to the flash tank 1 for flash evaporation at 0.2 MPa, separate part of the solvent ethanol at the top, and obtain the first concentrated solution of XDC whose temperature drops to 110°C at the bottom;

[0058] (2) Transfer the first concentrate of XDC obtained in step (1) to the solvent separation tower 2 for the first rectification (the pressure is 30kPa, the temperature of the tower is 120°C), the remaining solven...

Embodiment 2

[0068] This embodiment provides a method for the separation, purification and purification of the intermediate m-xylylenedicarbamate solution, the method comprising the following steps:

[0069] Provide XDC solution synthesized under high temperature and high pressure (3.6MPa, 210°C), the main components in the XDC solution include intermediate m-xylylene dicarbamate, solvent ethanol, carbonylating agent ethyl carbamate And trace impurities and by-products.

[0070] (1) Send the XDC solution to the flash tank 1 for flash evaporation at 0.1 MPa, separate part of the solvent ethanol at the top, and obtain the first concentrated solution of XDC whose temperature drops to 85°C at the bottom;

[0071] (2) Transfer the first concentrate of XDC obtained in step (1) to the solvent separation tower 2 for the first rectification (the pressure is 50kPa, the temperature of the tower bottom is 130°C), the remaining solvent ethanol is separated at the top of the tower, and XDC is obtained a...

Embodiment 3

[0081] This embodiment provides a method for the separation, purification and purification of the intermediate m-xylylenedicarbamate solution, the method comprising the following steps:

[0082] Provide XDC solution synthesized under high temperature and high pressure (1.7MPa, 180°C), the main components in the XDC solution include intermediate m-xylylene dicarbamate, diethyl carbonate, ethanol and trace impurities and by-product.

[0083] (1) Send the XDC solution to the flash tank 1 for flash evaporation at 0.15 MPa, separate part of the solvent ethanol at the top, and obtain the first concentrated XDC solution whose temperature drops to 110°C at the bottom;

[0084] (2) Transfer the first concentrate of XDC obtained in step (1) to the solvent separation tower 2 for the first rectification (the pressure is 80kPa, the temperature of the tower bottom is 90°C), the remaining solvent ethanol is separated at the top of the tower, and XDC is obtained at the bottom of the tower se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com