Antistatic liquid silicone rubber and preparation method thereof

A liquid silicone rubber and antistatic technology, which is applied in the field of antistatic liquid silicone rubber and its preparation, can solve the problem of failure to achieve comprehensive physical properties such as tensile strength, elongation at break, tear strength, etc., and the inability to balance physical strength and fluidity , unhealthy operators and other issues, to achieve the effect of changing the processing performance, physical machinery and weather resistance, excellent comprehensive physical properties, and reducing the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example is an antistatic liquid silicone rubber and its preparation method. Through the optimization of the formula and the control of the preparation process, an antistatic liquid silicone rubber with both physical strength and fluidity can be obtained, which can not only reduce the frequency of equipment failures, Moreover, its superior weather resistance and fatigue resistance can greatly improve the service life of the equipment.

[0062] The antistatic liquid silicone rubber described in this embodiment includes the following components in parts by weight: 100 parts of vinyl polydimethylsiloxane compound, 22 to 44 parts of modified reinforcing agent, modified conductive material 2-5 parts, platinum catalyst 0.2-0.5 parts, hydrogen-containing crosslinking agent 2-5 parts, polymerization inhibitor 0.02-0.05 parts, purified water 1-2 parts. in:

[0063] In order to meet the physical strength of liquid silicone rubber and take into account certain fluidity requir...

Embodiment 2

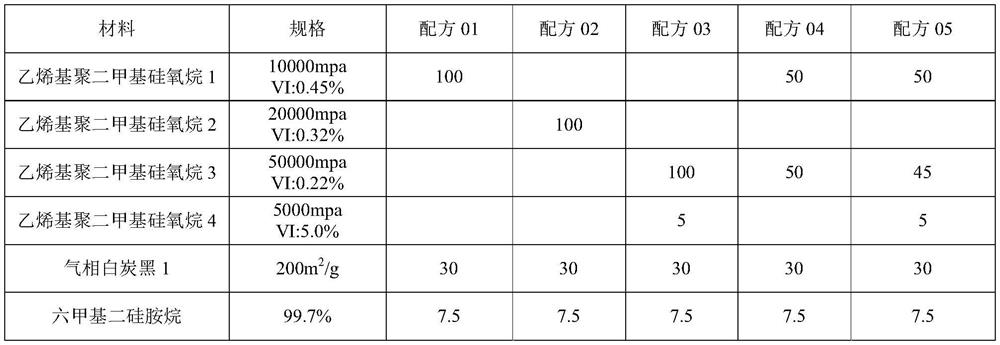

[0077] This example is to verify the necessity of selecting vinyl polydimethylsiloxane compound in order to satisfy the physical strength of liquid silicone rubber and take into account the fluidity of silicone rubber proposed in Implementation 1. In this implementation, the influence of using one kind of vinyl polydimethylsiloxane and a variety of vinyl polydimethylsiloxanes with different viscosities and different vinyl contents on the comprehensive performance of the rubber compound is compared. Concrete formulation is as shown in Table 1:

[0078] Table I:

[0079]

[0080] According to the formula in Table 1, the liquid silicone rubber base rubber was prepared according to the preparation method step S1 in Example 1, and its physical strength and fluidity were tested. The results are shown in Table 2:

[0081] Table II:

[0082] Performance unit Recipe 01 Recipe 02 Recipe 03 Recipe 04 Recipe 05 viscosity mPa 150000 180000 280000 220000...

Embodiment 3

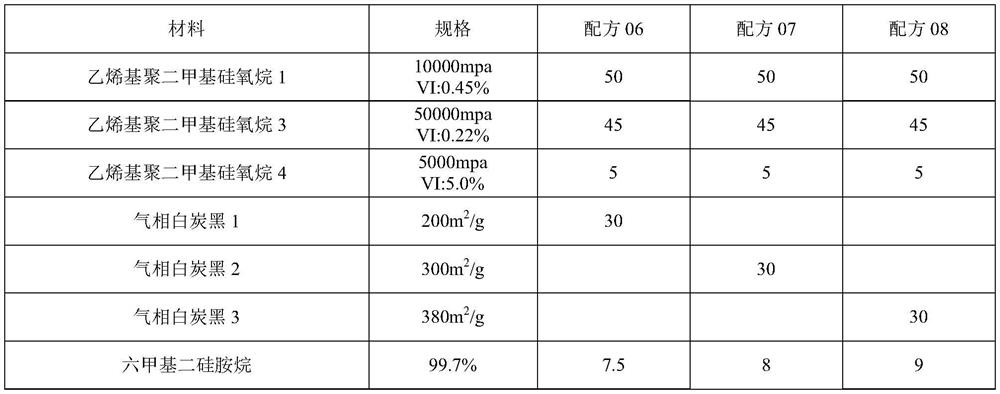

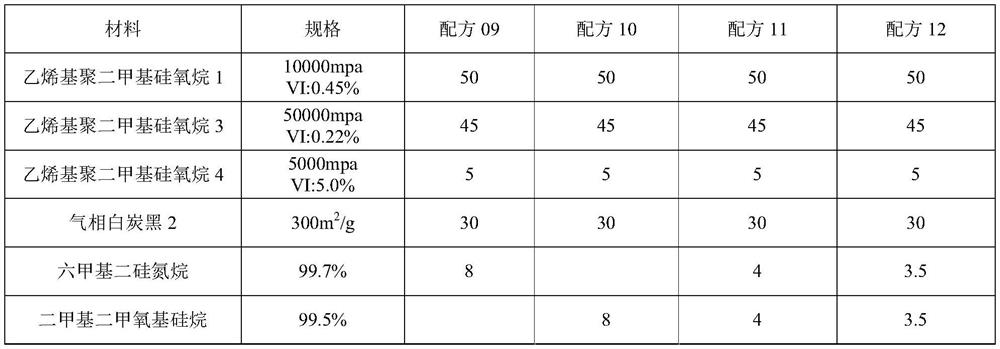

[0085] This embodiment is to verify that the specific surface area of modified fumed silica used in Example 1 improves the physical strength and fluidity of liquid silicone rubber. This embodiment uses fumed silica with different specific surface areas to test different The impact of the specification of fumed silica on the comprehensive performance of liquid silicone rubber, the design formula is shown in Table 3:

[0086] Table three:

[0087]

[0088] According to the formula in Table 3, the liquid silicone rubber base was also prepared according to the preparation method step S1 in Example 1, and its physical strength and fluidity were tested. The results are shown in Table 4:

[0089] Table four:

[0090] Performance unit Recipe 06 Recipe 07 Recipe 08 viscosity mPa 195000 230000 320000 hardness Shaw A 40 40 42 tensile strength MPa / m 2

[0091] It can be seen from the above table that the viscosity and tensile strength of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com