Preparation method of C.I. Pigment red 185

A pigment red and pigment technology, which is applied in the field of preparation of C.I. Pigment Red 185, can solve the problems of increasing the cost of wastewater treatment, and achieve the effects of reducing the treatment cost, making the particles soft and reducing the use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

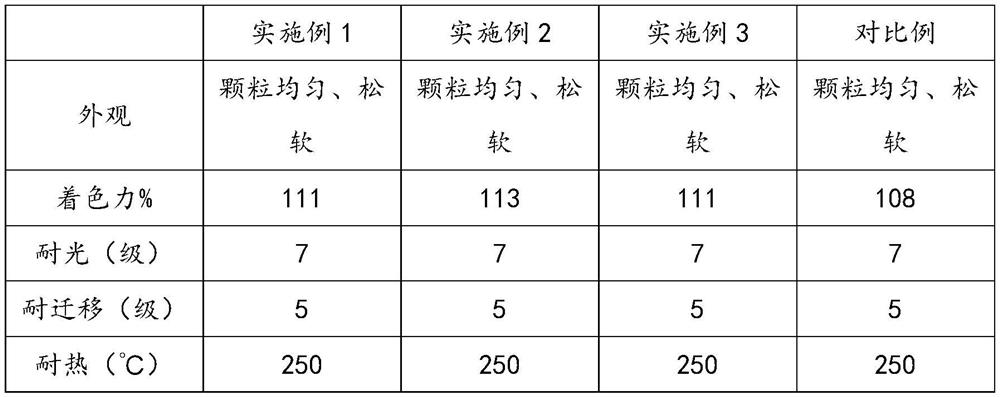

Examples

Embodiment 1

[0020] A preparation method of C.I. Pigment Red 185, comprising the steps of:

[0021] Step 1, add hydrochloric acid to water and stir evenly, then add 2-methoxy-4-methylaminosulfonyl-5-methylaniline and beat for 20 minutes at room temperature to obtain 2-methoxy-4-sulfonic acid-5-methyl Aniline slurry, standby; the hydrochloric acid is 30% hydrochloric acid, the mass ratio of the 2-methoxy-4-sulfonic acid-5-methylaniline is 10%, the 2-methoxy-4 - the pH of the sulfonic acid-5-methylaniline slurry is 6.5;

[0022] Step 2, adding aluminum nitrite to water and stirring evenly to dissolve, and adding hydrochloric acid dropwise to adjust the pH to obtain an aluminum nitrite solution; the mass ratio of the aluminum nitrite to water is 1:1.1, and the hydrochloric acid is 30% hydrochloric acid, and the adjusted pH is 6;

[0023] Step 3, put the 2-methoxy-4-sulfonic acid-5-methylaniline slurry into the ice bath, and slowly add the aluminum nitrite solution dropwise, constant tempera...

Embodiment 2

[0027] A preparation method of C.I. Pigment Red 185, comprising the steps of:

[0028] Step 1, add hydrochloric acid to water and stir evenly, then add 2-methoxy-4-methylaminosulfonyl-5-methylaniline and beat for 40 minutes at room temperature to obtain 2-methoxy-4-sulfonic acid-5-methyl Aniline slurry, for subsequent use; the hydrochloric acid is 30% hydrochloric acid, the mass ratio of the 2-methoxyl-4-sulfonic acid-5-methylaniline is 30%, the 2-methoxyl-4 - the pH of the sulfonic acid-5-methylaniline slurry is 6.8;

[0029] Step 2, adding aluminum nitrite to water and stirring evenly to form a solution, and adding hydrochloric acid dropwise to adjust the pH to obtain an aluminum nitrite solution; the mass ratio of the aluminum nitrite to water is 1:1.2, and the hydrochloric acid is 30% hydrochloric acid, and the adjusted pH is 6.5;

[0030] Step 3, put the 2-methoxy-4-sulfonic acid-5-methylaniline slurry into the ice bath, and slowly add the aluminum nitrite solution drop...

Embodiment 3

[0034] A preparation method of C.I. Pigment Red 185, comprising the steps of:

[0035] Step 1, add hydrochloric acid to water and stir evenly, then add 2-methoxy-4-methylaminosulfonyl-5-methylaniline and beat for 30 minutes at room temperature to obtain 2-methoxy-4-sulfonic acid-5-methyl Aniline slurry, standby; the hydrochloric acid is 30% hydrochloric acid, the mass ratio of the 2-methoxyl-4-sulfonic acid-5-methylaniline is 20%, the 2-methoxyl-4 - The pH of the sulfonic acid-5-methylaniline slurry is 6.7;

[0036] Step 2, adding aluminum nitrite to water and stirring evenly to dissolve, and adding hydrochloric acid dropwise to adjust the pH to obtain an aluminum nitrite solution; the mass ratio of the aluminum nitrite to water is 1:1.1, and the hydrochloric acid is 30% hydrochloric acid, and the adjusted pH is 5.3;

[0037] Step 3, put the 2-methoxy-4-sulfonic acid-5-methylaniline slurry into the ice bath, and slowly add the aluminum nitrite solution dropwise, constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com