Model predictive current overmodulation control method for two-level brushless direct current motor

A brushed DC motor, model prediction technology, applied in motor generator control, electronic commutation motor control, current controller and other directions, can solve problems such as high processing capacity requirements, large motor current, increased motor heating, etc., to achieve expansion The effect of speed range, improving dynamic and steady state performance, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

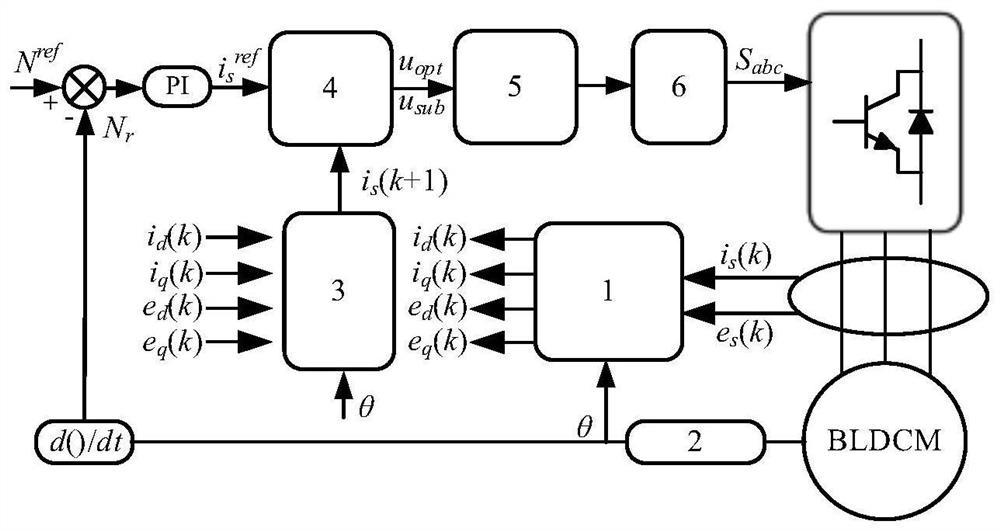

[0054] A method for predicting current overmodulation control with a two-level brushless DC motor model, comprising the steps of:

[0055] Step 1: Obtain the electrical angle θ from the encoder output signal e , and get the electrical angular velocity ω from formula (1) e ; Then divide the 2π electric angle in one operating cycle of the motor into six states (θ e ∈[mπ,(m+(1 / 3))π], where m=(0,1 / 3,2 / 3,1,4 / 3,5 / 3), six states can be obtained by piecewise linear method the e a 、e b and e c , get e from formula (2) a , get e from formula (3) b , get e from formula (4) c ; Then obtain the back electromotive force e of the αβ axis at k time through the Clark transformation of the formula (5) α (k) and e β (k); Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com