Middle coating for wet-on-wet coating process as well as preparation method and application of middle coating

A coating process, wet-on-wet technology, used in polyurea/polyurethane coatings, coatings, etc., to achieve the best water resistance, low VOC emission value, high leveling, improved adhesion and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

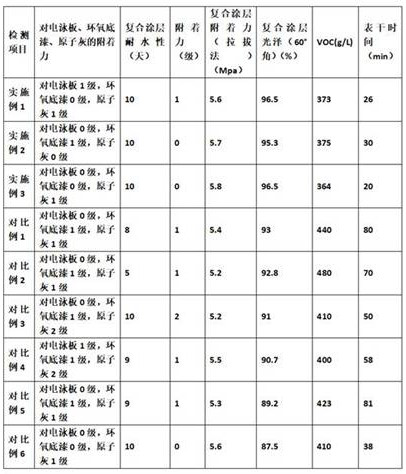

Embodiment 1

[0041] Embodiment 1 A kind of preparation method of intermediate coating coating for described wet-on-wet coating process

[0042] The preparation method of A component comprises the following steps:

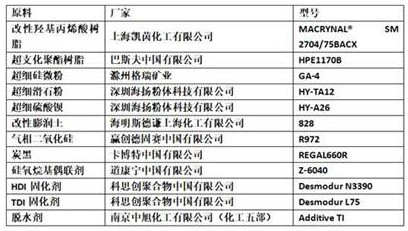

[0043] Step (1): Add 20 parts of modified hydroxyacrylic resin, 5 parts of hyperbranched polyester resin, 2 parts of PMA, 2 parts of BAC, 5 parts of xylene, 0.5 parts of BYK-110, 2 parts of superfine silica powder, 2 parts of talcum powder, 2 parts of superfine barium sulfate, 11 parts of titanium dioxide, 0.5 parts of modified bentonite, 0.3 parts of fumed silica, 0.2 parts of carbon black, pre-dispersed at 900 rpm, using a horizontal sand mill Grind to a fineness of less than 15um, control the powder outflow conditions to a temperature below 50°C, and a flow rate of 10 L / min to obtain a slurry;

[0044] Step (2): Add 0.1 part of BYK-331 to step (1), and stir for 5 minutes at 300 rpm;

[0045] Step (3): Put 0.01 part of drier air chemical T12 into step (1), and stir for 5-10 ...

Embodiment 2

[0049] Embodiment 2 A kind of preparation method of intermediate coating paint for wet-on-wet coating process

[0050] The preparation method of A component comprises the following steps:

[0051] Step (1): Add 30 parts of modified hydroxyacrylic resin, 11 parts of hyperbranched polyester resin, 5 parts of PMA, 4 parts of BAC, 15 parts of xylene, 1 part of BYK-110, 6 parts of superfine silica powder, and superfine talc 12 parts of powder, 12 parts of superfine barium sulfate, 23 parts of titanium dioxide, 0.8 parts of modified bentonite, 0.5 parts of fumed silica, 0.4 parts of carbon black, pre-dispersed at 1200 rpm, and ground with a horizontal sand mill When the fineness is less than 15um, control the outflow condition of the powder to be below 50°C, and the flow rate is 15L / min to obtain the slurry;

[0052] Step (2): Add 0.5 parts of BYK-331 to step (1), stir at 600 rpm for 10 minutes;

[0053] Step (3): Put 0.03 parts of drier air chemistry T12 into step (1), and stir f...

Embodiment 3

[0057] Embodiment 3 A kind of preparation method of intermediate coating paint for wet-on-wet coating process

[0058] The preparation method of A component comprises the following steps:

[0059] Step (1): Add 25 parts of modified hydroxyacrylic resin, 11 parts of hyperbranched polyester resin, 2.5 parts of PMA, 4 parts of BAC, 5 parts of xylene, 1 part of BYK-110, 3 parts of superfine silica powder, 12 parts of superfine talcum powder, 12 parts of superfine barium sulfate, 20 parts of titanium dioxide, 0.5 parts of modified bentonite, 0.3 parts of fumed silica, 0.2 parts of carbon black, pre-dispersed at 1000 rpm, using horizontal sand Grind with a mill until the fineness is below 15um, control the powder outflow conditions to be below 50°C, and flow at 15L / min to obtain a slurry;

[0060] Step (2): Add 0.3 parts of BYK-331 to step (1), stir at 300 rpm for 10 minutes;

[0061] Step (3): Put 0.01 parts of drier air chemistry T12 into step (1), and stir for 5-10 minutes at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com