Adhesive with double functions of electromagnetic shielding and heat conduction for electronic packaging and preparation method of adhesive

A technology of electromagnetic shielding and electronic packaging, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high cost, complex preparation method, restricted development, etc., and achieve high peel strength and high thermal conductivity. , the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

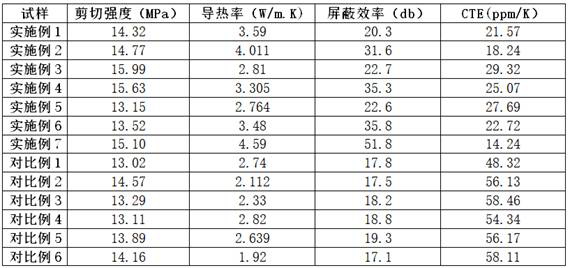

Examples

Embodiment 1

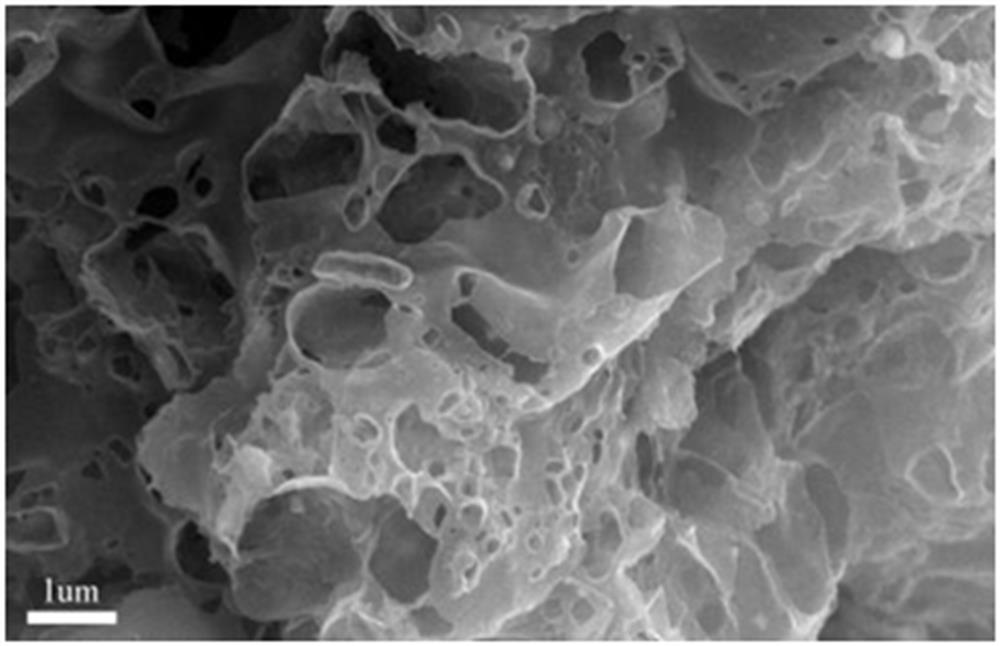

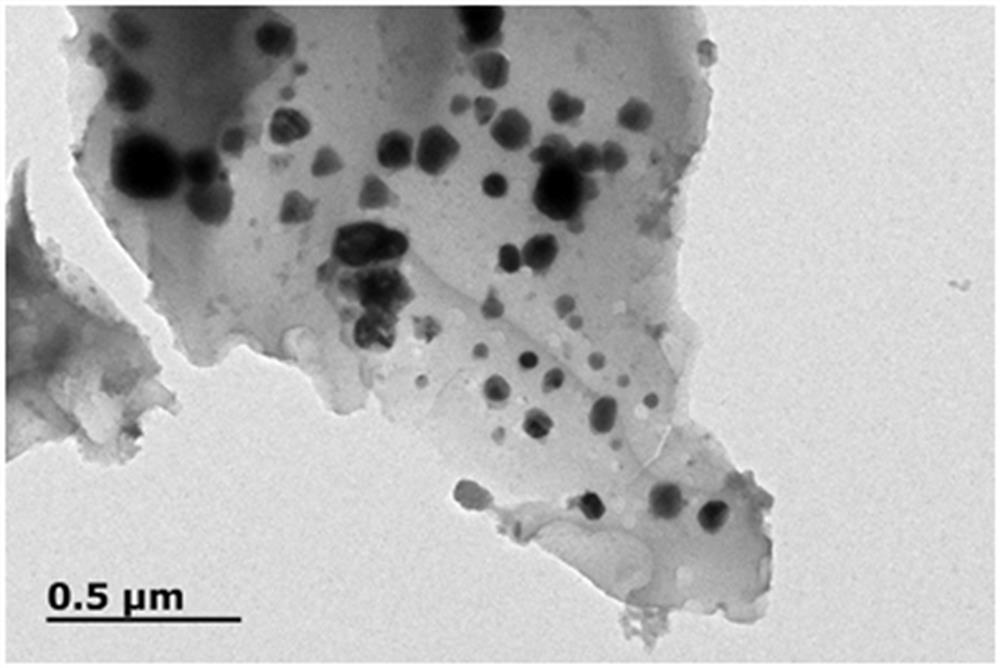

[0042] Add 5 parts of silicone-modified epoxy resin, 30 parts of bisphenol A epoxy resin, 5 parts of polypropylene glycol diglycidyl ether and 5 parts of additives into the double planetary dynamic mixing kettle in sequence, turn on revolution stirring and high-speed dispersion, Stir for 1 hour at a temperature of 25°C, add 10 parts of Ni nanoparticle / C composite material and 37 parts of spherical alumina, stir for 0.5 hours, add 7 parts of dicyandiamide and 0.5 parts of organic urea, stir for 1 hour, and finally add gas phase 0.5 parts of silicon dioxide, stirred, and after the infiltration of gas phase silicon dioxide, the vacuum pump was turned on for vacuum degassing, the vacuum pressure was 0.09MPa, and after keeping for 0.5h, an electromagnetic shielding and heat conduction dual-function adhesive for electronic packaging was obtained. The stirring speed is 50r / min, and the high-speed dispersion speed is 800r / min.

[0043] The Ni nanoparticle / C composite material is carri...

Embodiment 2

[0049] Referring to the preparation method of Example 1, the mass ratio of Ni nanoparticles / C composite material to spherical alumina was changed to 20:27.

Embodiment 3

[0051]Add 8 parts of polyurethane modified epoxy resin, 30 parts of bisphenol A epoxy resin, 8 parts of o-cresyl glycidyl ether and 5 parts of additives into the double planetary dynamic mixing kettle in sequence, turn on revolution stirring and high-speed dispersion, and Stir for 1 hour at a temperature of 25°C, add 10 parts of Fe nanoparticle / C composite material and 27.8 parts of spherical alumina, stir for 0.5 hours, add 10 parts of dicyandiamide and 0.7 parts of organic urea, stir for 1 hour, and finally add gas phase two 0.5 parts of silicon oxide, stirred, and after the fumed silica was infiltrated, the vacuum pump was turned on for vacuum degassing, the vacuum pressure was 0.09MPa, and after keeping for 0.5h, an electromagnetic shielding and thermally conductive dual-functional adhesive for electronic packaging was obtained. The rotating speed is 50r / min, and the high-speed dispersion rotating speed is 800r / min.

[0052] The Fe nanoparticles / C composite material is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com