Saccharomyces cerevisiae for producing Maotai flavor and application thereof

A technology of Saccharomyces cerevisiae and soy sauce, which is applied in the fields of application, fungi, biochemical equipment and methods, etc. It can solve the problems of insufficient strong taste, limited aroma substances, and inability to solve the problem of soy sauce flavor, so as to improve the fresh and sweet taste and Thickness, fast speed, and the effect of improving the lack of sauce flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

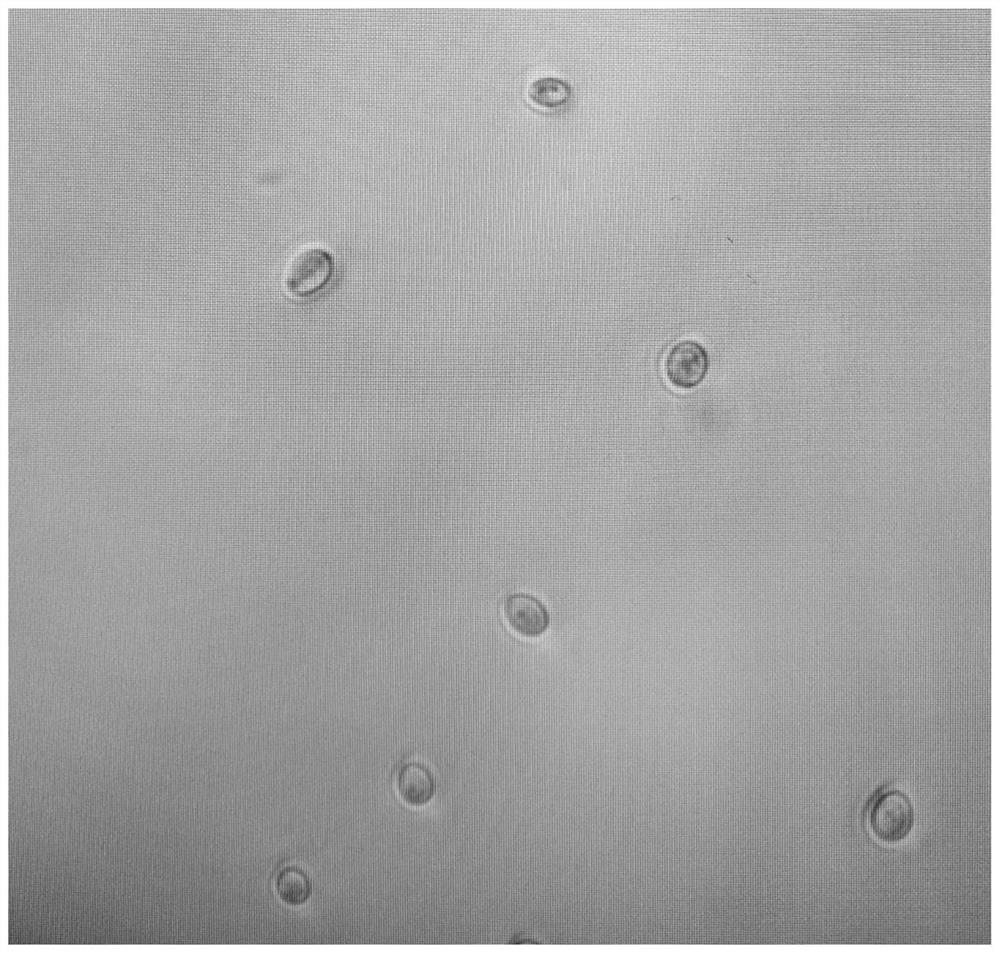

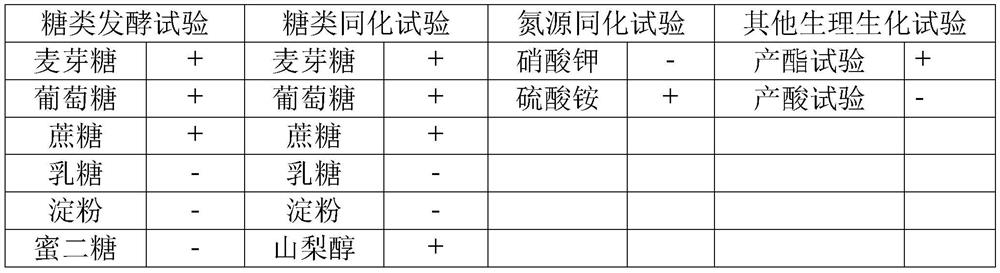

[0069] Embodiment 1, the acquisition of Saccharomyces cerevisiae ZB433 bacterial strain

[0070] Saccharomyces cerevisiae (Saccharomyces cerevisiae) ZB433 screening of the initial strain before mutagenesis, including the following screening process:

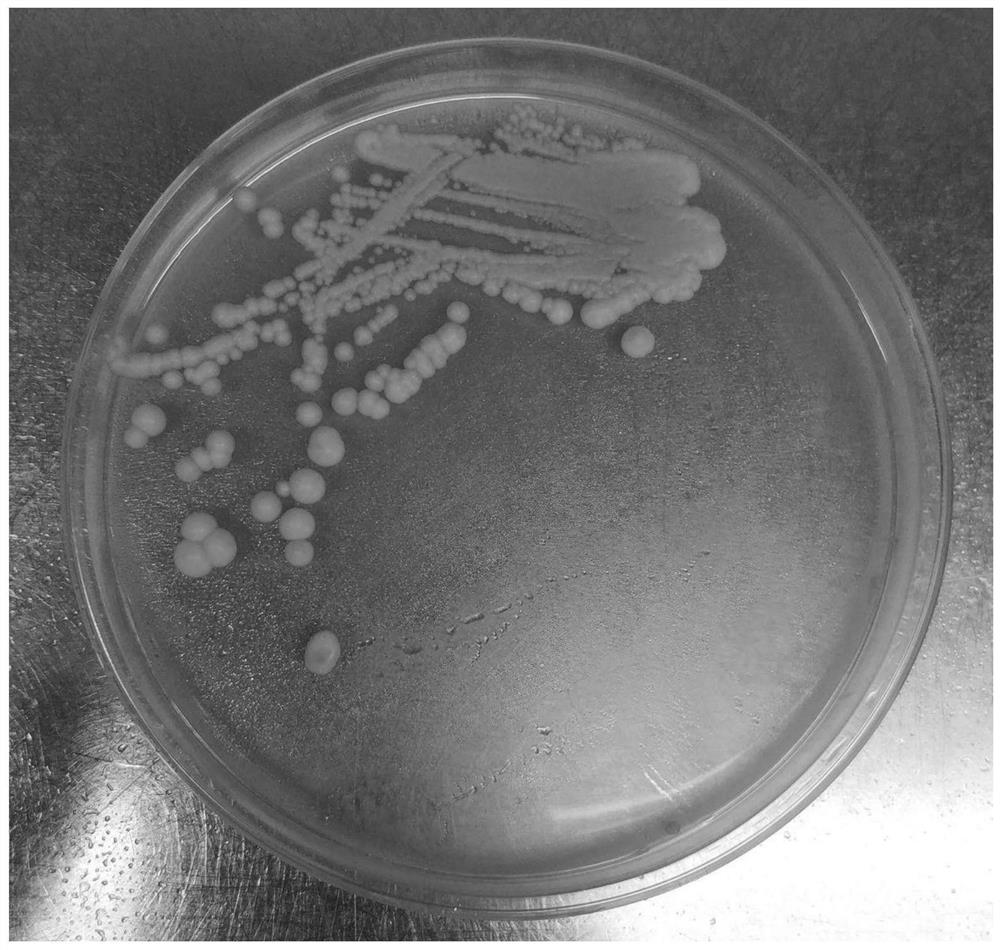

[0071] 1. Strain isolation

[0072] Ferment soy sauce from Foshan Haitian (Gaoming) Seasoning Food Co., Ltd., add sterile water at a mass ratio of 1:9 to make a suspension, and then gradiently dilute to 10% with sterile normal saline. -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 After doubling, take 0.1mL of the diluted solution and spread it on the PDA medium with a salt content of 10wt%, culture it at 30°C for 48 hours, select a single colony for further streak isolation and purification for 3 times, and inoculate the purified strain on the slant PDA medium conservation on.

[0073] YPD liquid medium: 1wt% yeast extract, 2wt% peptone, 2wt% glucose and water.

[0074] An additional 2wt% agar was added to the YPD solid or slan...

Embodiment 2

[0153] Embodiment 2, the application in soy sauce fermentation

[0154] The PD liquid medium containing 18wt% sodium chloride was used to cultivate the Saccharomyces cerevisiae ZB433 described in the embodiment of the present invention, and the mutagenesis starting strain Saccharomyces cerevisiae CX20FJ185, 30°C, 180rpm shaking culture for 48h, to obtain the cell activity High seed culture solution with high bacterial density.

[0155] The raw materials soybean and wheat flour are made into koji by discs, and then the koji is added to salt water for fermentation. When the amino acid nitrogen in the fermentation system is ≥0.8g / 100mL, the seed culture solution is inoculated and fermented for 7d~10d, and the fermentation management is carried out according to the conventional method. .

[0156] After the fermentation is completed, check the routine physical and chemical indicators of soy sauce, use GC-MS to measure guaiacol and 4-ethylguaiacol, use the alloxan method to measu...

Embodiment 3

[0166] Embodiment 3, the application in soybean paste brewing

[0167] Using soybeans and wheat flour as raw materials, carry out soybean paste koji making according to conventional methods, add 1.8 times of salt water with a weight concentration of 18% (m / m) into the koji, and ferment after mixing. When the amino acid nitrogen in the fermentation system is ≥0.8 g / 100mL inoculated seed culture solution was fermented for 7d to 10d, and the fermentation management was carried out according to conventional methods. The seed culture liquids are Saccharomyces cerevisiae ZB433 seed liquid and Saccharomyces cerevisiae CX20FJ185 seed liquid respectively.

[0168] After the fermentation was completed, the routine physical and chemical indicators of soybean paste were detected, guaiacol and 4-ethylguaiacol were determined by GC-MS, the content of glutathione was measured by alloxan method, and the flavor of soybean paste was tested. Evaluation results are shown in the table below.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com