Long nozzle coating temperature adjusting system and method in continuous casting production

A technology of temperature regulation system and long nozzle, which is applied in casting equipment, casting melt container, manufacturing tools, etc., can solve the problems of lack of effective means for the stability of molten steel in tundish and large fluctuation of molten steel temperature in tundish. It is beneficial to the quality of steel smelting and the effect of small fluctuation of molten steel temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

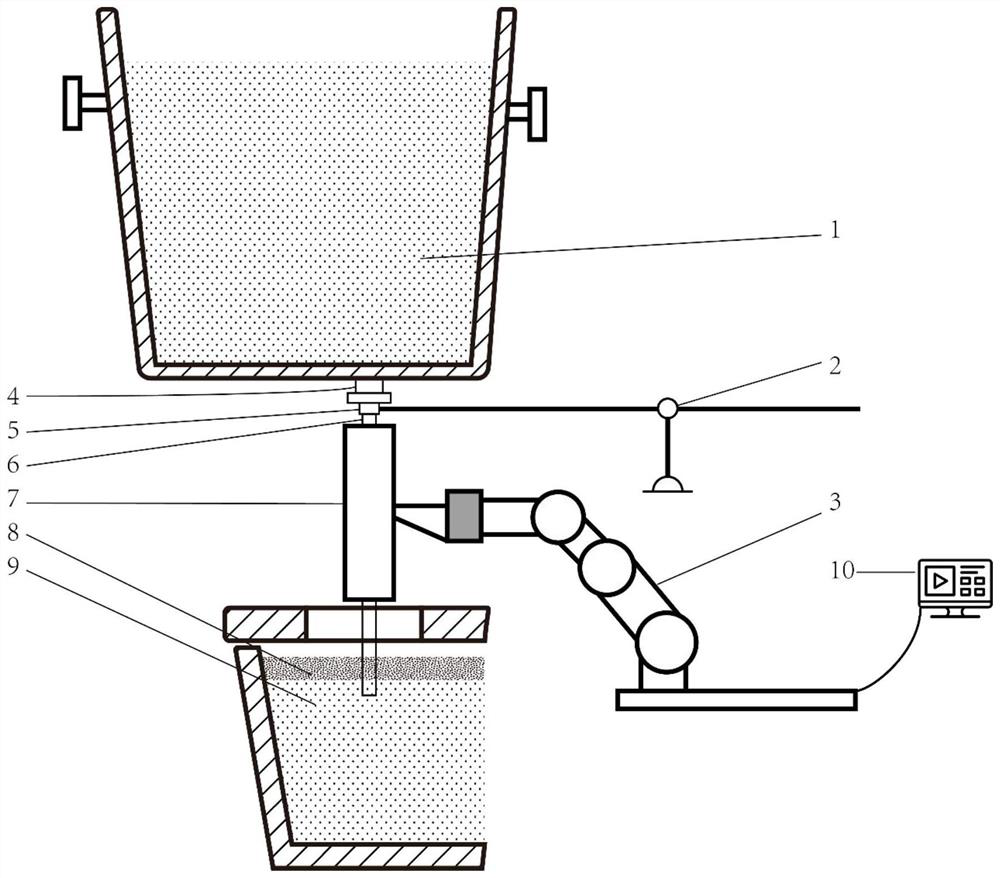

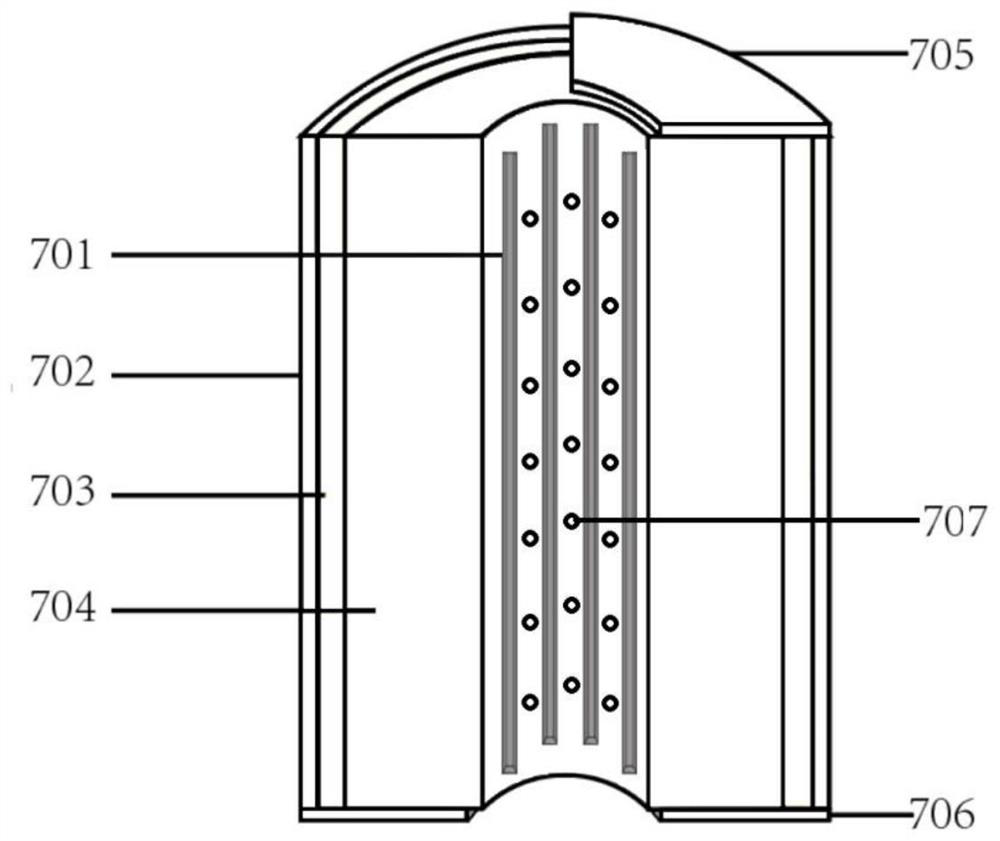

[0045] In a continuous casting factory, the molten steel in ladle 1 is 100 tons, the length of the long nozzle 6 is 1450mm, the length of the upper bowl is 120mm, the outer diameter of the lower part of the bowl is 165mm, and the depth of the lower end of the molten steel during continuous casting is 200mm; The temperature jacket 7 is composed of two semicircular temperature regulating walls, with an inner diameter of 167mm, an outer diameter of 567mm and a length of 1000mm; the outer shell of the temperature regulating jacket and the upper and lower ends are welded by 3mm thick high-temperature stainless steel 310S, and the upper and lower ends of the stainless steel are welded by 310S. The outer diameter of the sheet is 567mm and the inner diameter is 169mm; a layer of refractory cotton 703 is placed close to the inner side of the stainless steel, with a refractoriness of 1200°C and a thickness of 20mm; the innermost layer is a lightweight alumina foam brick 704 with a refract...

Embodiment 2

[0049] In a continuous casting factory, the quality of molten steel in ladle 1 is 80 tons, the length of the long nozzle 6 is 1500 mm, the length of the upper bowl is 140 mm, the outer diameter of the lower part of the bowl is 150 mm, and the depth of the molten steel inserted at the lower end during continuous casting production is 250 mm; The shape thermostat 7 is composed of two semicircular thermostat walls, the inner diameter is 152mm, the outer diameter is 500mm, and the length is 950mm; The outer diameter of the stainless steel shell is 500mm and the inner diameter is 154mm; a layer of refractory cotton 703 is placed close to the inner side of the stainless steel shell, with a refractoriness of 1200°C and a thickness of 20mm; the innermost layer is a lightweight alumina foam brick 704 with a thickness of 151mm , the length is 904mm; the alumina foam brick is close to the side of the long nozzle, inlaid with iron-chromium-aluminum resistance wire, and the heating power is...

example 3

[0053] In a continuous casting factory, the mass of molten steel in ladle 1 is 120 tons, the length of the long nozzle 6 is 1400 mm, the length of the upper bowl is 130 mm, the outer diameter of the lower part of the bowl is 160 mm, and the depth of the lower end of the molten steel inserted during continuous casting production is 230 mm; The shape temperature regulating sleeve 7 is composed of two semicircular temperature regulating walls, the inner diameter is 162mm, the outer diameter is 500mm, and the length is 1000mm; The outer diameter of the stainless steel sheet is 500mm and the inner diameter is 164mm; a layer of refractory cotton 703 is placed close to the inner side of the stainless steel shell, with a refractoriness of 1200°C and a thickness of 20mm; the innermost layer is a lightweight alumina foam brick 704 with a refractoriness of 1650℃, thickness is 147mm, length is 956mm.

[0054] Before the continuous casting production starts, preheat the temperature regulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com