Preparation method of anisotropic heat-conducting phase-change energy-storage wood

A phase-change energy storage, anisotropic technology, applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of inefficient utilization and qualitative transmission of heat energy, poor high thermal conductivity, etc., to achieve efficient utilization and qualitative The effect of transmission, high thermal conductivity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

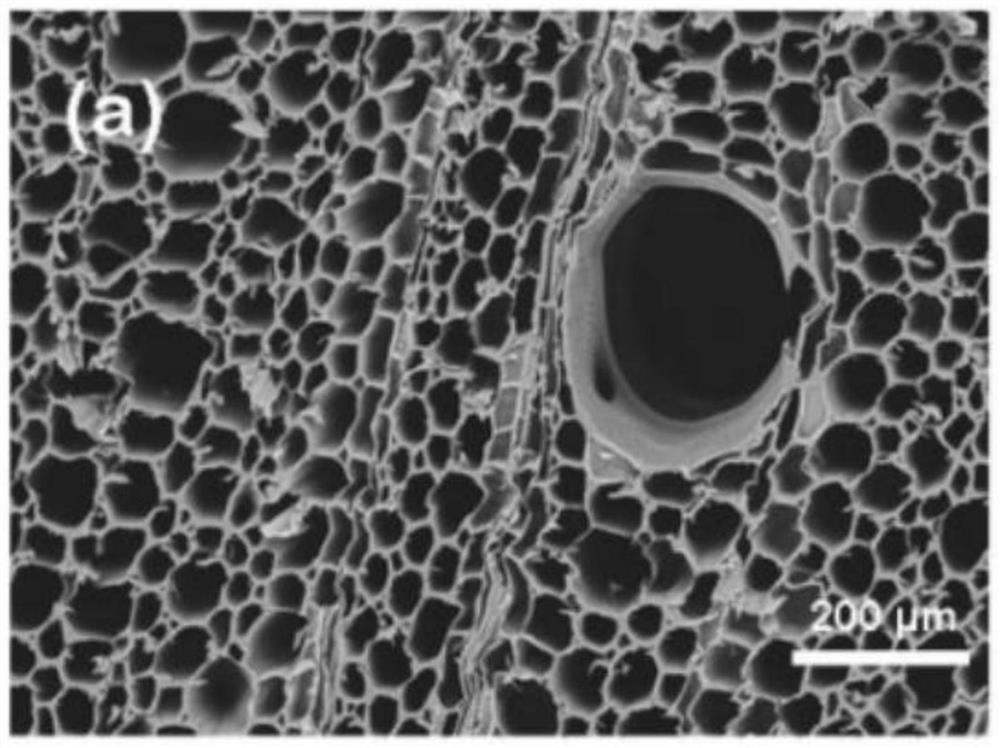

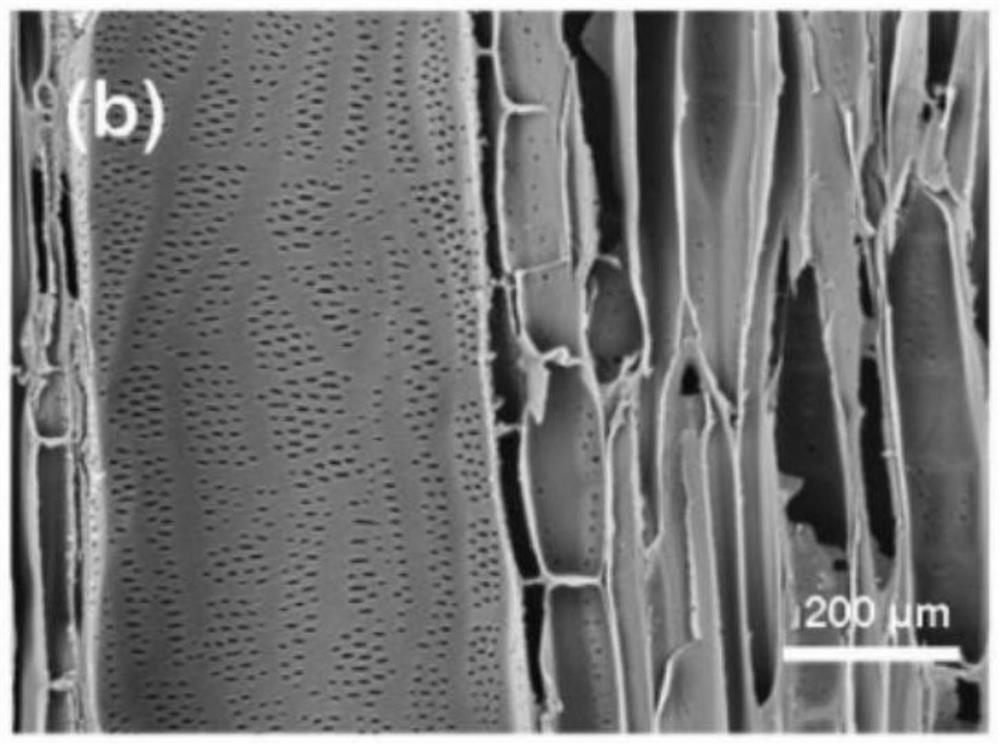

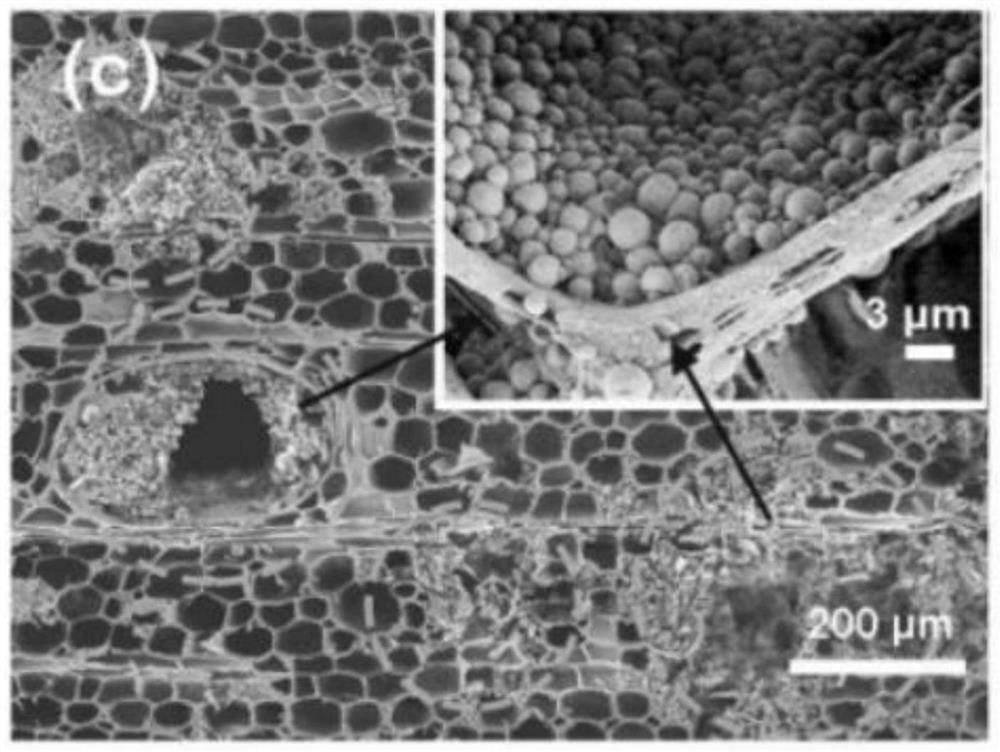

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of preparation method of anisotropic thermal conductivity phase change energy storage wood, carry out according to the following steps:

[0034] Step 1. Mix 7g of melamine, 8g of urea, 28g of formaldehyde and 35ml of deionized water by mass, add triethanolamine to adjust pH to 8.5-9, and then heat at 80°C for 35 minutes to obtain a prepolymer;

[0035] Step 2: Dissolve 8g of styrene-maleic anhydride copolymer (SMA) and 2g of NaOH in 90ml of deionized water by mass, and heat at 80° C. for 70 minutes to obtain a yellow and transparent SMA solution;

[0036] Step 3, adding the SMA solution of 10g and the n-octadecane of 8g to the prepolymer in step 2 by mass, and emulsifying for 35 minutes at 6500 rpm to obtain a phase change emulsion;

[0037] Step 4, heating the phase change emulsion at 55°C for 25 minutes, then heating to 75°C for 3 hours to obtain a phase change microcapsule suspension;

[0038] Step 5. Put the wood whose length×width×height is 20...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of anisotropic thermal conductivity phase change energy storage wood, carry out according to the following steps:

[0042] Step 1. Mix 9g of melamine, 6.5g of urea, 32g of formaldehyde and 28ml of deionized water by mass, add triethanolamine to adjust pH to 8.5-9, then heat at 78 ° C for 35 minutes to obtain a prepolymer ;

[0043] Step 2: Dissolve 12g of styrene-maleic anhydride copolymer (SMA) and 3g of NaOH in 85ml of deionized water by mass, and heat at 82° C. for 65 minutes to obtain a yellow and transparent SMA solution;

[0044] Step 3, adding the SMA solution of 8g and the n-octadecane of 10g to the prepolymer in step 2 by mass, and emulsifying at 5500 rpm for 40 minutes to obtain a phase change emulsion;

[0045] Step 4, heating the phase change emulsion at 50°C for 35 minutes, then heating to 65°C for 2.5 hours to obtain a phase change microcapsule suspension;

[0046] Step 5. Put the wood whose length×width×height ...

Embodiment 3

[0049] Embodiment 3: a kind of preparation method of anisotropic thermal conductivity phase change energy storage wood, carry out according to the following steps:

[0050] Step 1. Mix 7.7g of melamine, 7.4g of urea, 29.9g of formaldehyde and 30ml of deionized water in parts by mass, add triethanolamine to adjust the pH to 8.5-9, and then heat at 80°C for 30 minutes to obtain a aggregate;

[0051] Step 2: Dissolve 10 g of styrene-maleic anhydride copolymer (SMA) and 3 g of NaOH in 87 ml of deionized water by mass, and heat at 80° C. for 60 minutes to obtain a yellow and transparent SMA solution;

[0052] Step 3, add the SMA solution of 9g and the n-octadecane of 8g to the prepolymer in step 2 by mass, and emulsify at 6000 rpm for 30 minutes to obtain a phase change emulsion;

[0053] Step 4, heating the phase change emulsion at 50°C for 30 minutes, then heating to 70°C for 2.5 hours to obtain a phase change microcapsule suspension;

[0054] Step 5. Put the wood whose length×wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com