Preparation method and application of Ru-ZnFexOy heterogeneous nanosheet modified porous carbon material

A porous carbon material, nanosheet technology, applied in the direction of electrolysis components, electrodes, energy input, etc., can solve the problems of low conductivity, negative impact on maintaining the original structure, etc., to make up for high costs, reduce production costs and time, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

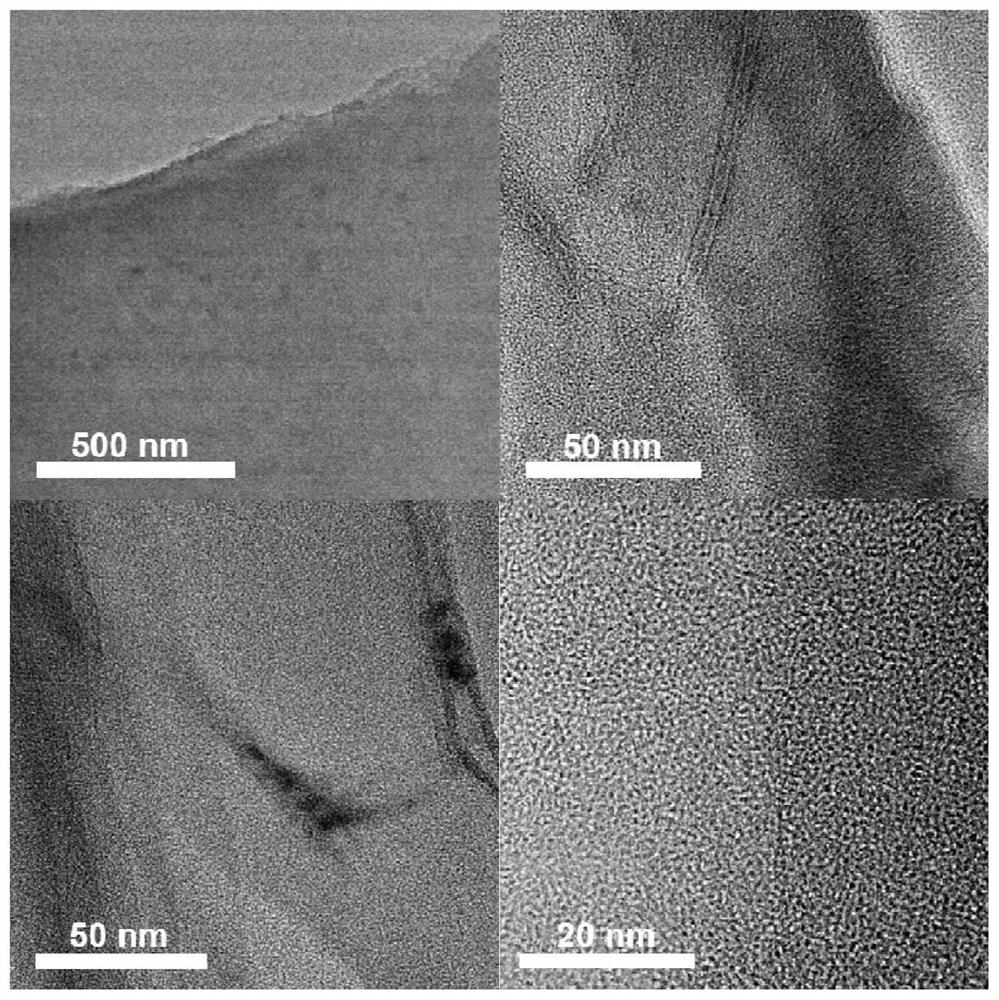

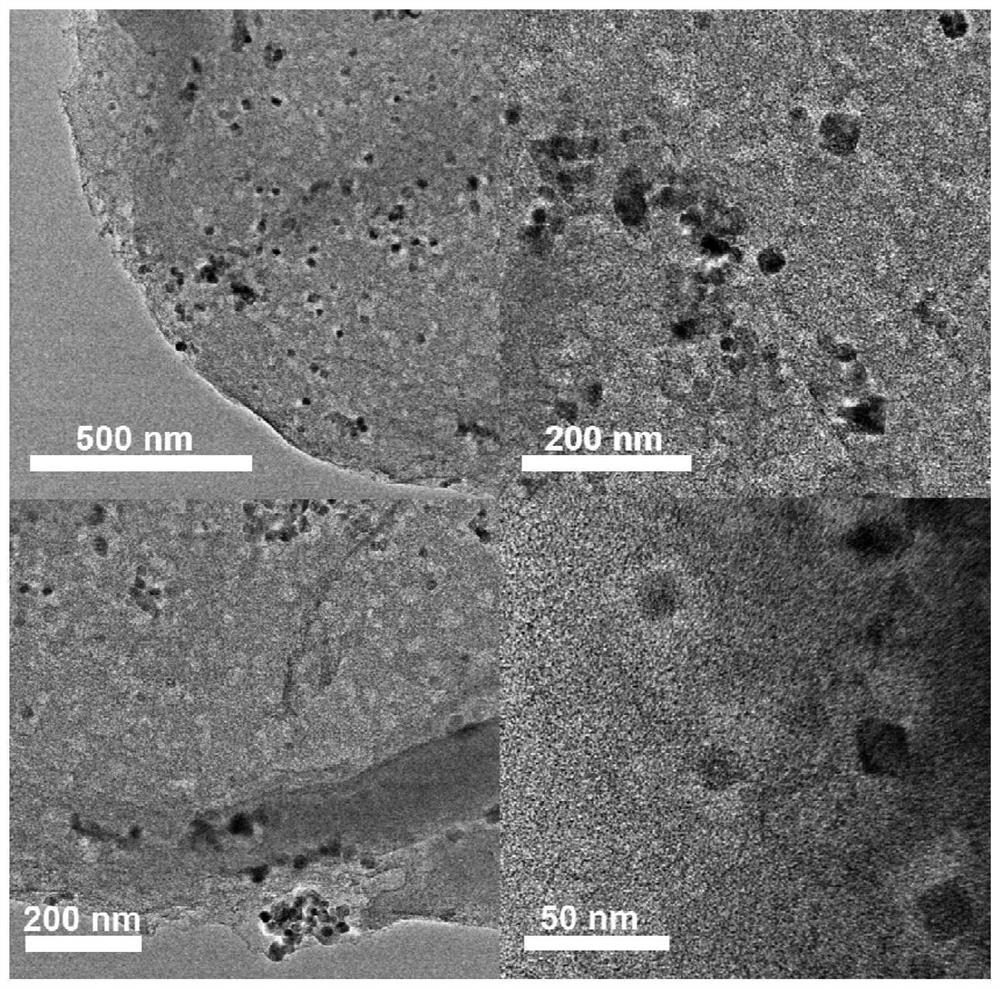

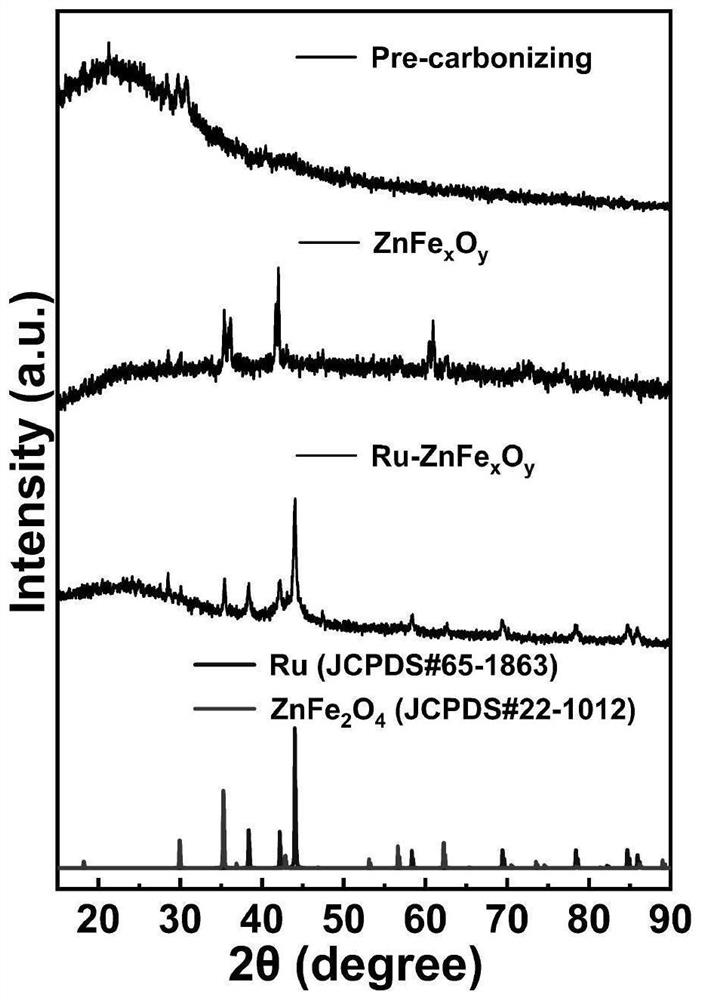

[0034] A Ru-ZnFe x O y The preparation method of the heterogeneous nanosheet modified porous carbon material includes the following steps: washing the mushroom waste residue with distilled water, drying it in a 90°C oven, taking part of the mushroom waste residue and placing it in a clean alumina porcelain boat, and placing it in a tubular In the furnace, in an argon atmosphere, heat up to 350°C at a heating rate of 5°C / min, keep at this temperature for 1 hour, cool down to a certain temperature, take out and grind into powder to obtain a pre-carbonized product. Its shape is from figure 1 The TEM characterization results shown appear to be porous carbon nanosheets. from Figure 4 The XRD characterization results show that an obvious C peak appears when the diffraction angle is 22 degrees, and the surface is mainly composed of carbon elements. from Figure 5 It can be seen from the XPS characterization results that the pre-carbonized product is mainly composed of C and O, ...

Embodiment 2

[0038] A Ru-ZnFe x The preparation method of Oy heterogeneous nanosheet-modified porous carbon material includes the following steps: washing the mushroom waste with distilled water, drying it in a 90°C oven, taking part of the mushroom waste and placing it in a clean alumina porcelain boat, and placing it in a tube In the furnace, in an argon atmosphere, heated to 400°C at a heating rate of 4°C / min, maintained at this temperature for 0.5h, cooled to a certain temperature, taken out and ground into powder to obtain a pre-carbonized product.

[0039] Further, at room temperature, weigh 300mg pre-carbonized product, 200mg ZnCl 2 and 900mg FeCl 3 ·6H 2 O, fully grind and mix, transfer to an alumina ark, place in a tube furnace protected by nitrogen atmosphere, heat to 850°C at a rate of 4°C / min, hold for 1.5h, cool down to a certain temperature and collect the sample, then heat The collected samples were repeatedly washed and vacuum filtered 3 times until the samples were neut...

Embodiment 3

[0042] A Ru-ZnFe x O y The preparation method of the heterogeneous nanosheet modified porous carbon material includes the following steps: washing the mushroom waste residue with distilled water, drying it in a 90°C oven, taking part of the mushroom waste residue and placing it in a clean alumina porcelain boat, and placing it in a tubular In the furnace, in an argon atmosphere, heat up to 300°C at a heating rate of 6°C / min, keep at this temperature for 1.5h, cool down to a certain temperature, take out and grind into powder to obtain a pre-carbonized product.

[0043] Further, at room temperature, weigh 200mg pre-carbonized product, 300mg ZnCl 2 and 800mg FeCl 3 ·6H 2 O, fully grind and mix, transfer to an alumina ark, place in a tube furnace protected by nitrogen atmosphere, heat to 750 ℃ at a rate of 6 ℃ / min, hold for 2.5 h, cool down to a certain temperature and collect the sample, and then heat The collected samples were repeatedly washed and vacuum filtered 3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com