High-strength and high-toughness graphite and preparation method thereof

A high-toughness, high-strength technology, applied in the field of high-strength and high-toughness graphite and its preparation, can solve the problems of low strength, low toughness, high transportation risk, etc., and achieve the effect of increasing density, strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

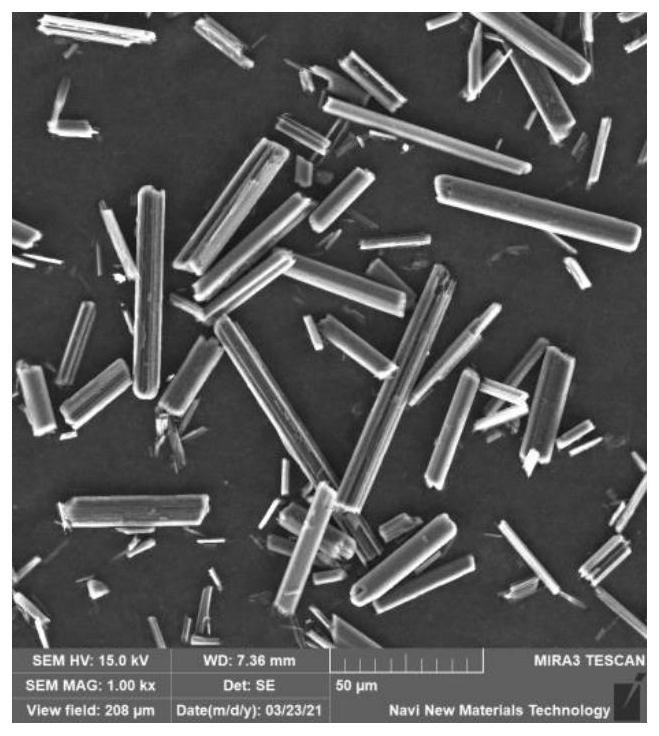

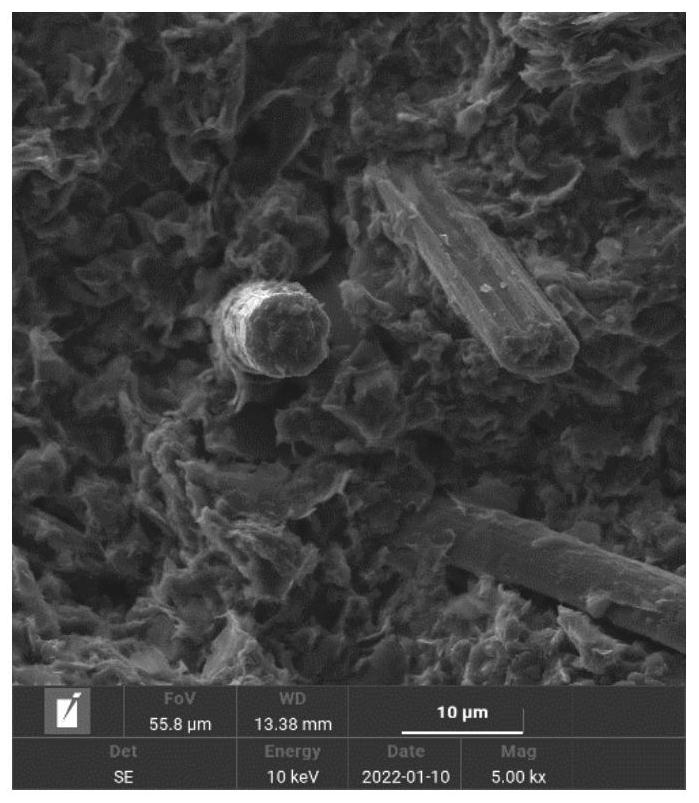

[0091] Prepare pitch coke and carbon chopped fibers in a mass ratio of 92:8, pour them into a conical mixer, and mix them thoroughly for 1 hour, then take them out.

[0092] Pour the uniformly mixed powder raw materials into a double-shaft stirring kneader with a Z-shaped reamer, and heat up while stirring. When the temperature rose to 180°C, the molten coal pitch was added to the kneader. The mass ratio of powder raw material (pitch coke + chopped fiber) to coal pitch was 65:35. After stirring at a constant temperature of 180°C for 2 hours, the heating was stopped, and the mixed paste was taken out.

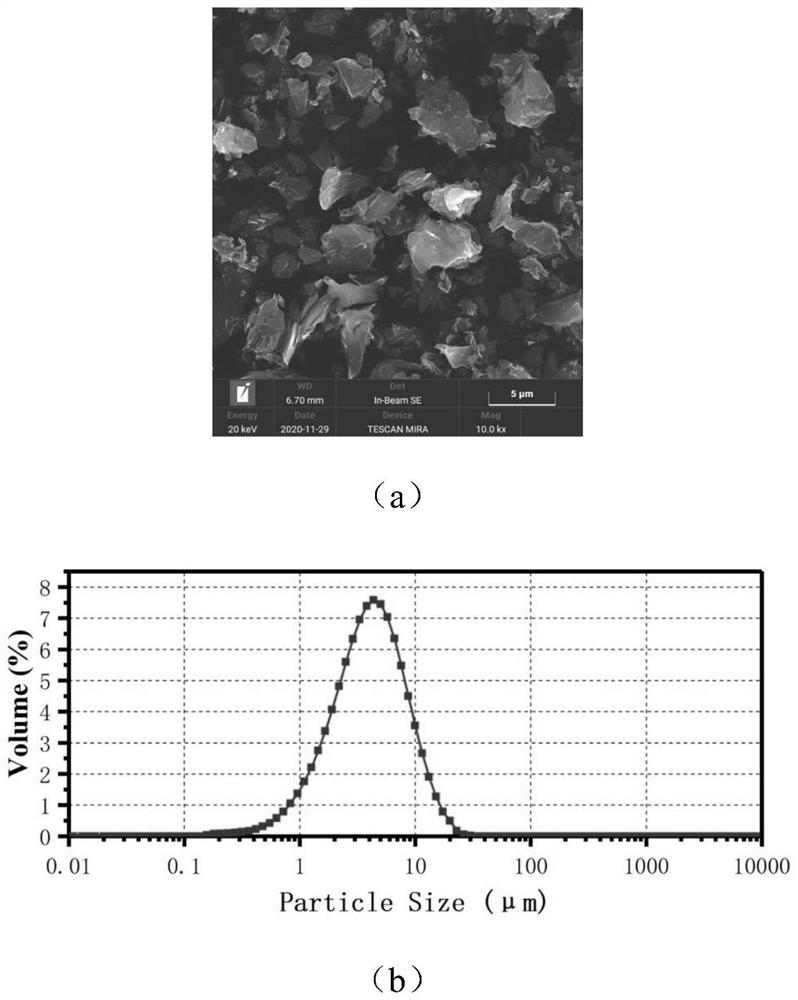

[0093] After the paste is cooled, use a small mechanical pulverizer to pulverize it, and the pulverized powder passes through a 150-mesh sieve. The sieved powder was loaded into a rubber mold with an inner diameter of 28 mm and a height of 300 mm and compacted. The loaded mold is sealed and placed in a cold isostatic press for molding, with a pressurizing pressure of 150 MPa a...

Embodiment 2

[0097] Compared with Example 1, except the carbonization process is different, the rest are the same. Only the carbonization process will be described below, and other steps refer to Example 1.

[0098] One carbonization:

[0099] The formed green body was heated to 1000°C at 20°C / h for a carbonization, and kept for 3h; and a nitrogen atmosphere was introduced throughout the whole process, and the nitrogen flow rate was 100ml / min. After the heat preservation is completed, the heating is stopped, and the carbonization process is completed after the carbonization furnace is naturally cooled to room temperature and the products are taken out.

[0100] One dip:

[0101] The green body after the primary carbonization was placed in an impregnation tank equipped with impregnated coal tar pitch, and the temperature of the impregnation tank was raised to 200° C. while the impregnation tank was evacuated, and the pressure was maintained under the condition of 0.2 atmospheres for 20 mi...

Embodiment 3

[0108] It is the same as Example 2 except that the mass ratio of pitch coke to chopped carbon fiber is 85:15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com