Foaming adhesive tape applied to automobile EPDM (Ethylene-Propylene-Diene Monomer) sealing strip and preparation method thereof

A foam and sealing strip technology, applied in the field of foam tape and its preparation, can solve the problems of low surface energy, complex process, cohesive damage and sticking, etc., to achieve improved bonding performance, simple preparation process, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

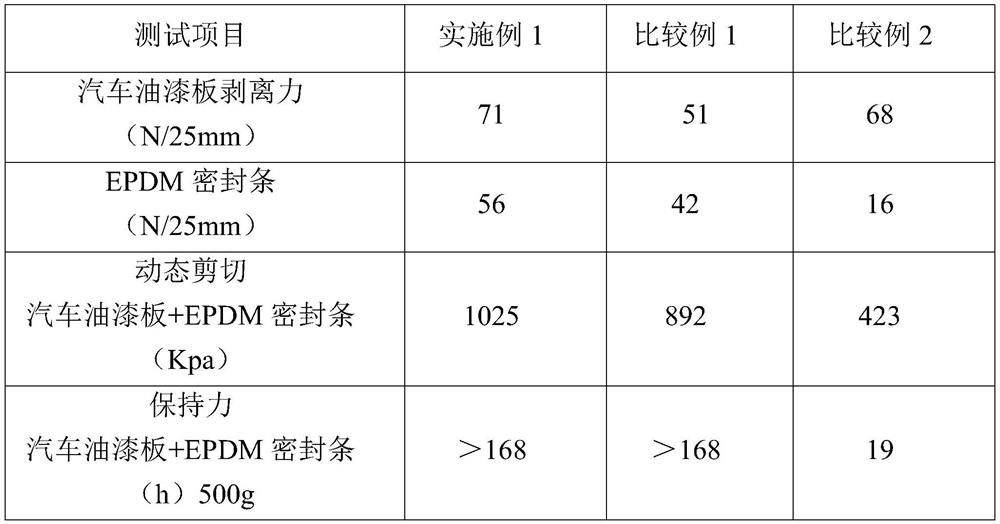

Examples

preparation example Construction

[0032] Preparation method of foaming body tape applied to automotive EPDM sealing strip, comprising the following steps:

[0033] C1, weigh the low molecular weight acrylic acid prepolymer for 40-50 parts, high molecular weight acrylic prepolymer for 10-20 parts, stir for 1h, completely mix evenly, and then add to the first area of the twin screw extruder;

[0034] C2, add 10-20 parts of block copolymer, 10-30 parts of tackifying resin, 0.2-1 part of antioxidant, 0.2-0.5 parts of carbon black to the second region of the twin screw extruder, the temperature is 150 °C;

[0035] C3, and then further add the foaming powder to the third area of the twin screw extruder, the temperature is 160 °C, to obtain the foam glue;

[0036] C4, finally mixed evenly, coated 0.8-1.1mm thick foam gel into the cooling roller, after cooling to transfer to the release film, and then with the EB electron beam curing cross-linked molding, rewind to obtain foam body tape.

Embodiment 1

[0038] C1, weigh the low molecular weight acrylic acid prepolymer for 52 parts, high molecular weight acrylic acid prepolymer for 14.5 parts, stir for 1h, completely mix evenly, and then add to the first area of the twin screw extruder;

[0039] C2, add 20 parts of block copolymer, 11 parts of tackifying resin, 0.2 parts of antioxidant, 0.3 parts of carbon black to the second area of the twin screw extruder, the temperature is 150 °C;

[0040] C3, and then further add the foaming powder to the third zone of the twin screw extruder, the temperature is 160 °C, to obtain the foam glue;

[0041] C4, finally mixed evenly, coated with 1.1mm thick styrofoam into the cooling roller, after cooling transferred to the release film, and then with the EB electron beam for curing cross-linking molding, rewinding to obtain foam body tape.

[0042] Wherein, the block copolymer is a multi-peak asymmetrical star-shaped block copolymer, the block copolymer using Kraton D1124; the tackifying resin us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com