Preparation method and application of flexible large-area full-inorganic perovskite waterproof luminescent fiber membrane

A light-emitting fiber, inorganic calcium technology, applied in the chemical characteristics of fibers, nanotechnology for materials and surface science, nano-optics, etc. The effect of high stability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

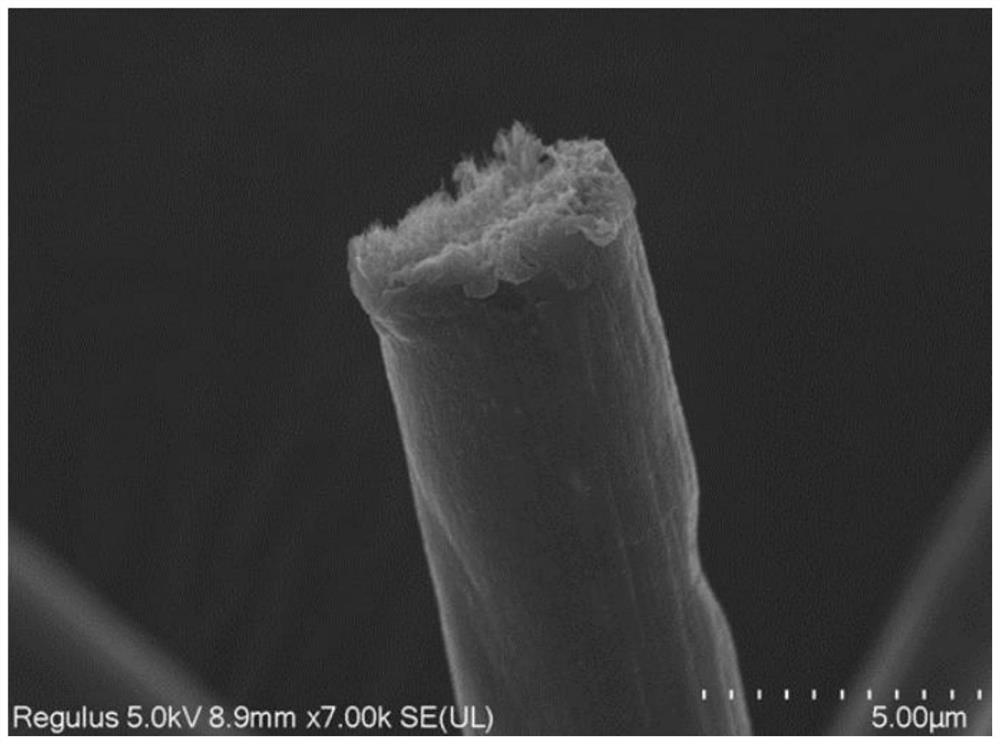

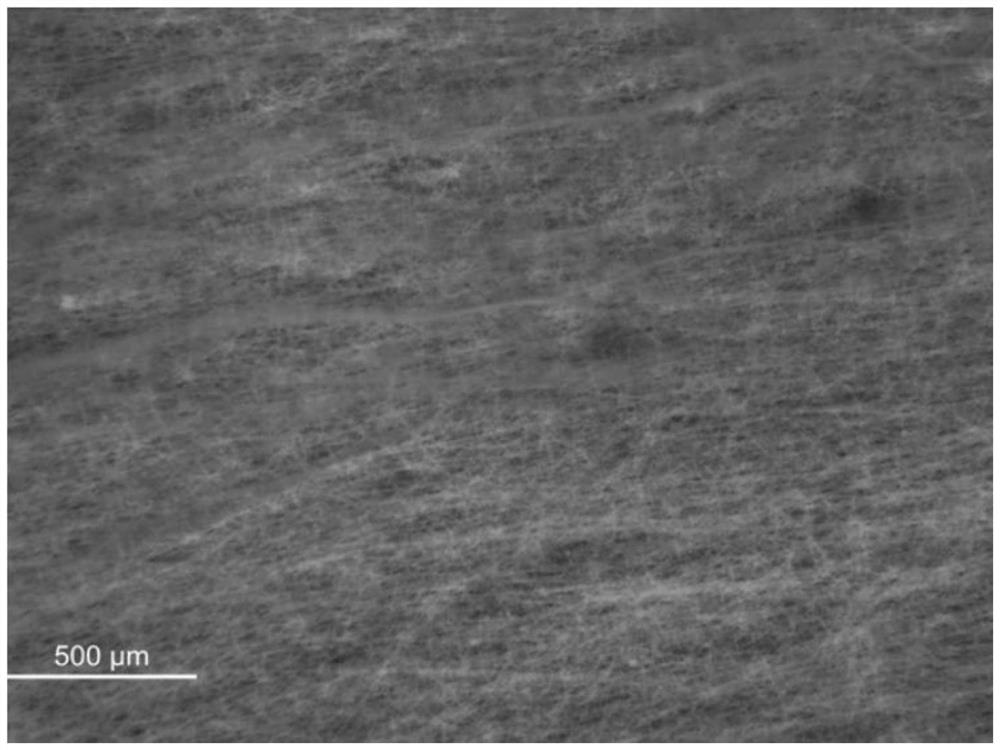

[0047] Embodiment 1 A kind of preparation method of all-inorganic perovskite waterproof light-emitting fiber membrane

[0048] The specific preparation method includes the following steps:

[0049] (1) Weigh 0.1M CsBr and 0.1M PbBr 2 Dissolve in 1 mL of DMF and stir well (4-8 hours) to obtain all-inorganic perovskite ABX 3 precursor solution;

[0050] (2) Prepare a PS (polystyrene) / DMF (N,N-dimethylformamide) resin solution with a mass fraction of 20%, and then add 750uL of the precursor solution to 5mL of the PS resin solution, Preparation of spinning solution 1;

[0051] (3) Add 0.01g β-cyclodextrin (a kind of cyclodextrin) and 150uL triethoxy-tridecafluoro-N-octylsilane (a kind of fluorine-containing silane) to 1mL of spinning solution 1 , the spinning solution 2 was made after stirring for 60 minutes;

[0052] (4) Put the spinning solution 2 into the syringe, then put the syringe into the pushing device, paste a layer of fiber cloth or metal aluminum foil on the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com