Turbine expansion power generation system based on ORC waste heat recovery and optimization method

A technology of turbo expansion and power generation system, which is applied to engine components, combustion engines, machines/engines, etc. It can solve problems such as small adjustment range, high power density, and increased system power consumption, so as to ensure sealing reliability and high-speed stability Good performance, avoiding the effect of leakage of working fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the invention clearer, the invention will be described in further detail below with reference to the accompanying drawings and citing preferred embodiments. It is to be understood, however, that many of the details set forth in the specification are merely intended to provide the reader with a thorough understanding of one or more aspects of the invention, which may be practiced without these specific details.

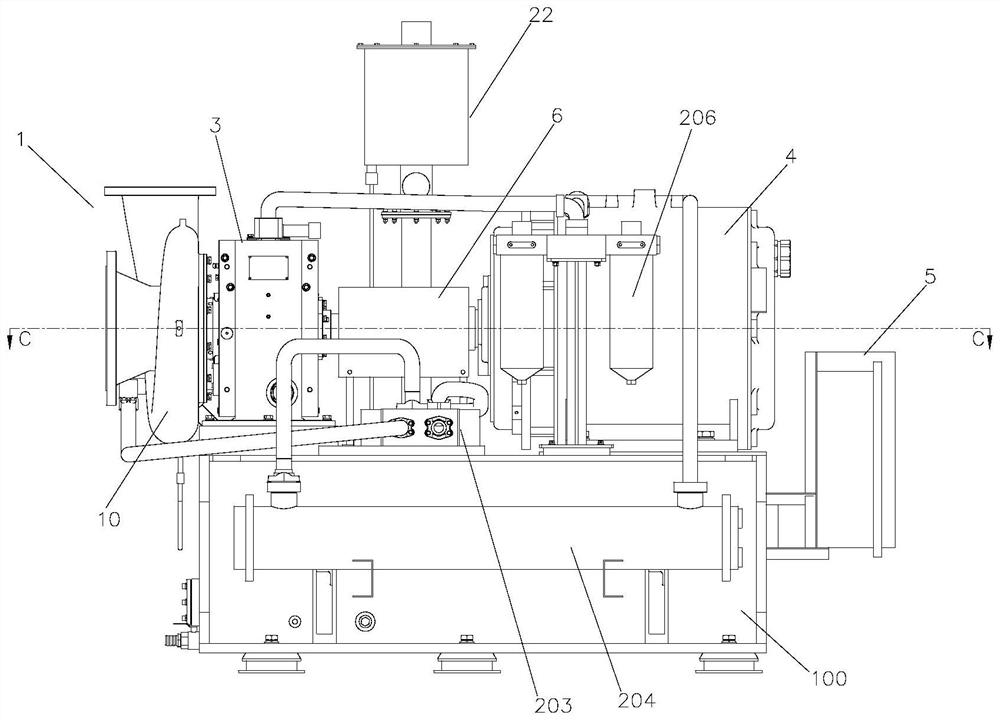

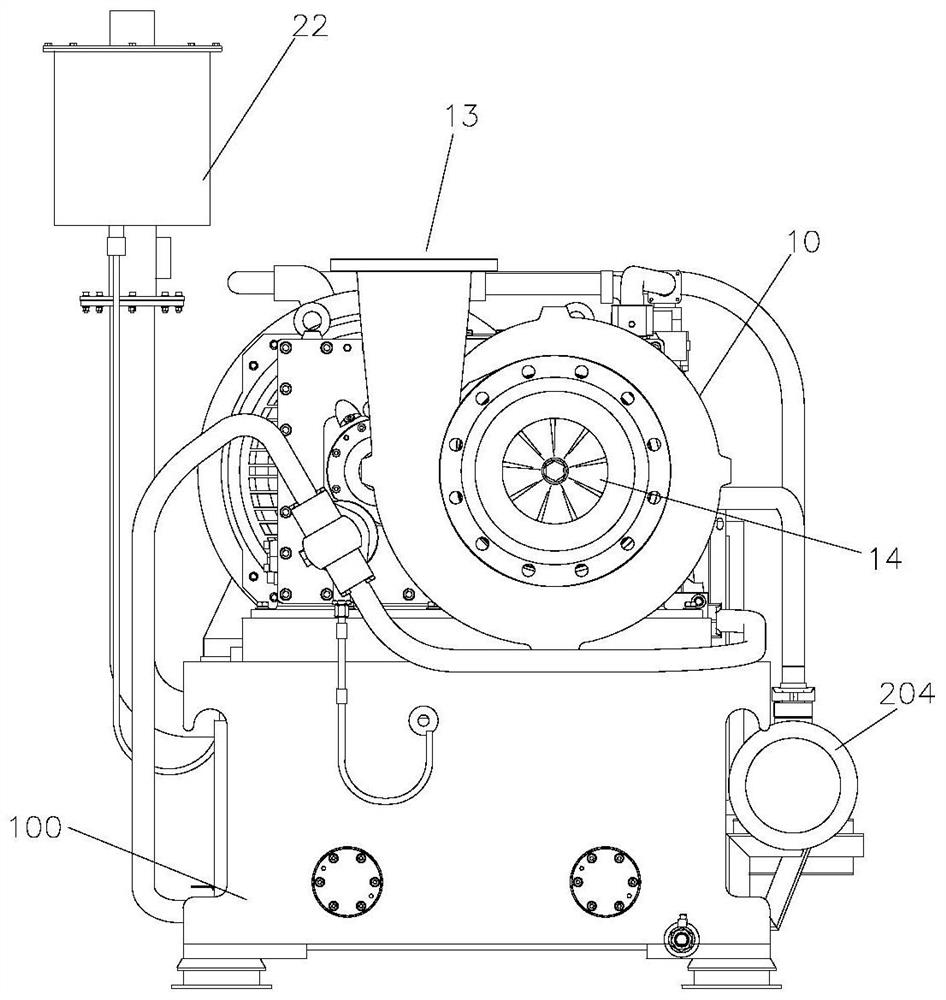

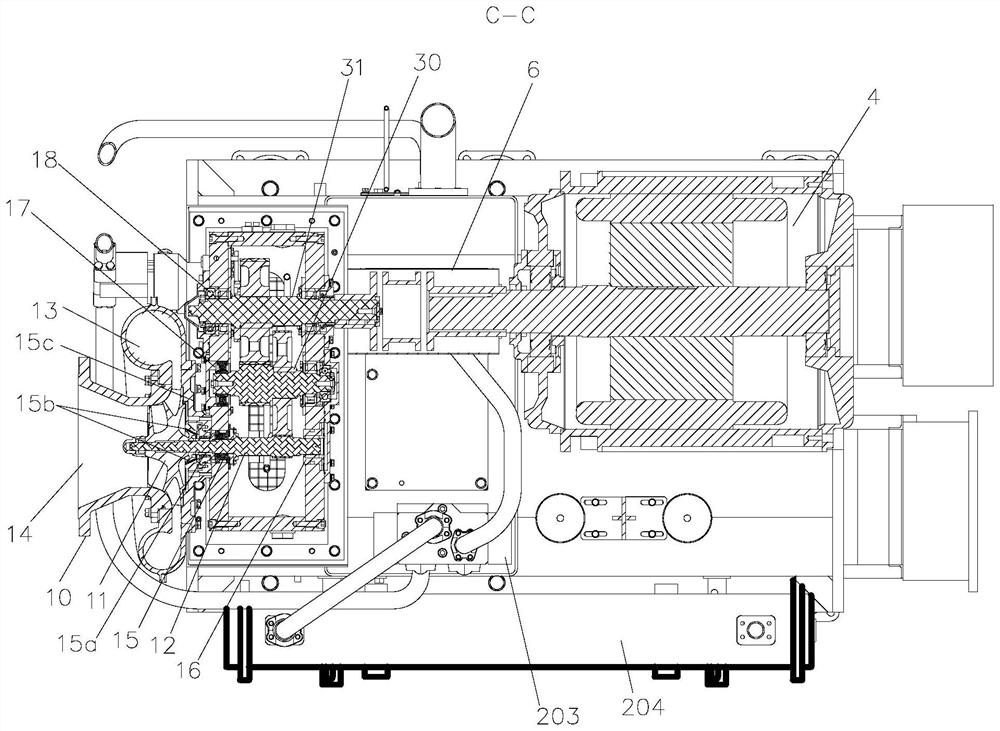

[0032] combine figure 1 and figure 2 As shown, according to a high-efficiency turbo-expansion power generation system for ORC waste heat recovery according to the invention, the turbo-expansion power generation system includes an installation base 100, an oil supply system 2 and a turbine installed on the installation base 100 from left to right A flat expander assembly 1, a gearbox 3 and a high-efficiency permanent magnet synchronous generator 4, the oil supply system 2 is communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com