Ink direct-writing 3D printing conductive polymer-based miniature supercapacitor and preparation method thereof

A technology of supercapacitors and conductive polymers, applied in the field of electrochemical energy storage, to achieve high electrochemical performance, high load capacity, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment includes the following steps:

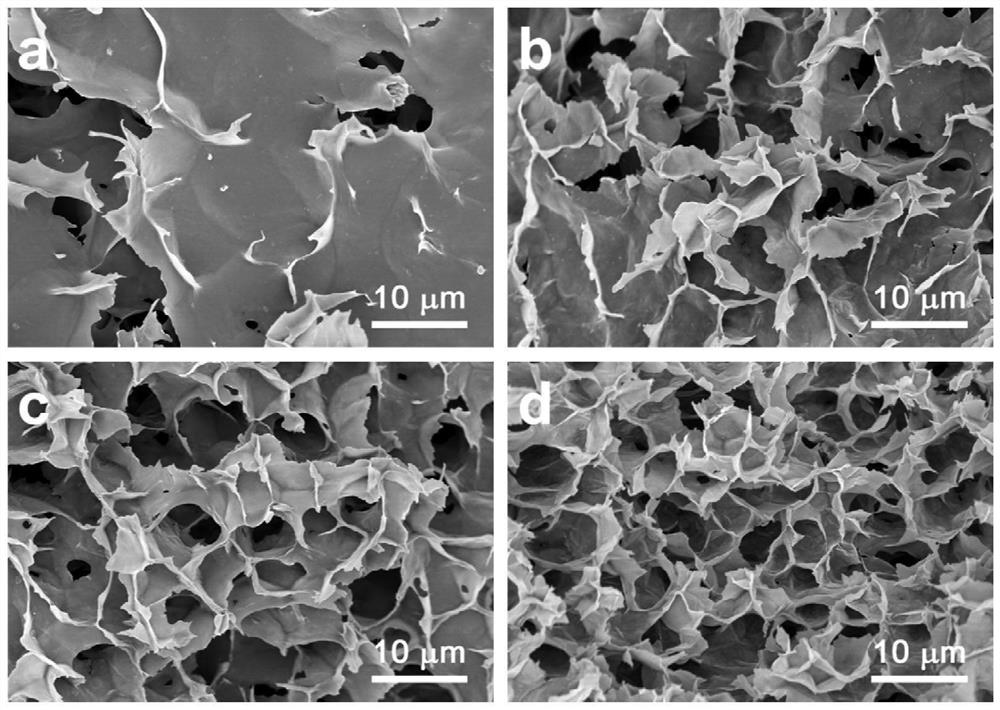

[0048] (1) 4g lithium fluoride was added to 80mL of 9M hydrochloric acid, dissolved for 30min, then 4g of MAX phase ceramic material was added to the mixed solution, etched at 35°C for 24h to obtain the MXene phase, and then washed to neutrality, The supernatant was collected by ultrasonic for 15min and then centrifuged for 30min to obtain MXene dispersion. Finally, freeze-dried MXene and PEDOT:PSS were obtained by freeze-drying MXene dispersion and commercial PH1000 aqueous solution;

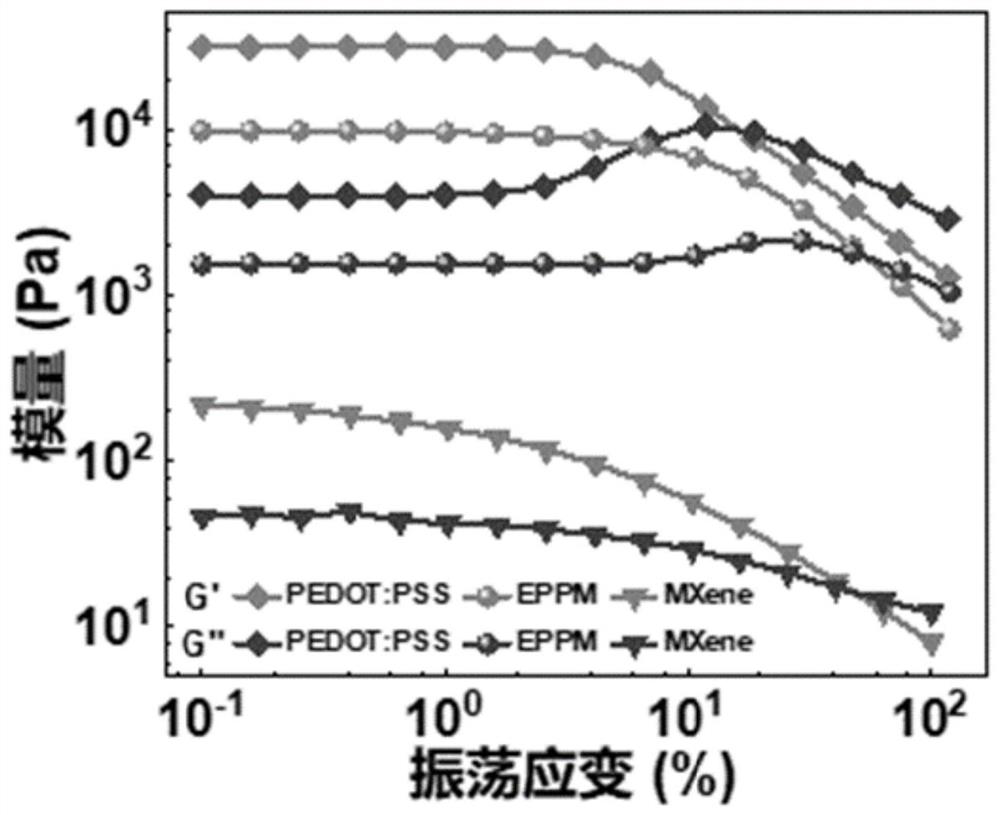

[0049] (2) Stir and mix 2.4 mL of water and 0.6 mL of ethylene glycol to obtain 3 mL of mixed solvent (volume ratio is 4:1), weigh 0.18 g of MXene and add it to the mixed solvent, and ultrasonically disperse it for 60 minutes. 0.18g of PEDOT:PSS was added to the mixed solution, stirred for 120min and mixed evenly to obtain a total concentration of 120mg mL -1 of printable inks (1:1 mass ratio of PEDOT:PSS and MXene);

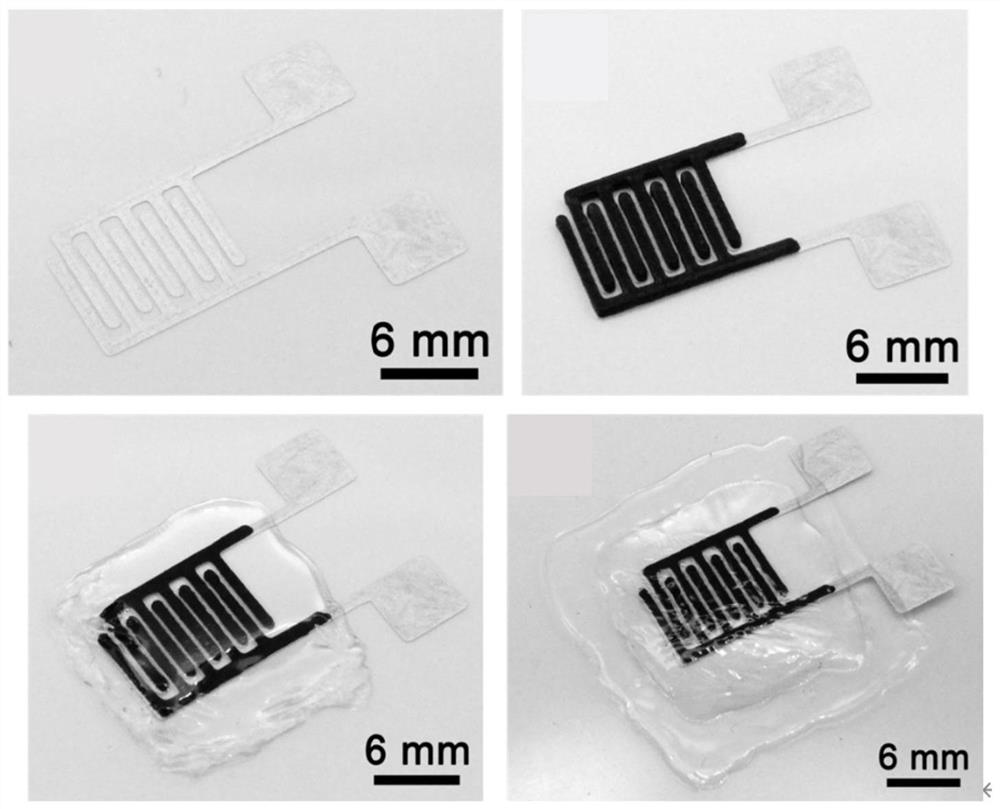

[0050] (3) Select a...

Embodiment 2

[0054] The mass ratio of PEDOT:PSS to MXene in Example 1 was changed to 3:1 (to keep the total concentration unchanged), and the rest were the same as in Example 1, and the final obtained micro-supercapacitor was recorded as EPPM-2.

Embodiment 3

[0056] The mass ratio of PEDOT:PSS to MXene in Example 1 was changed to 5:1 (to keep the total concentration unchanged), and the rest were the same as in Example 1, and the final obtained micro supercapacitor was recorded as EPPM-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com