Solid electrolyte, and electrode mixture, solid electrolyte layer, and solid-state battery using same

A solid electrolyte, solid state battery technology, applied in the field of electrode mixture, can solve problems such as hydrogen sulfide generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

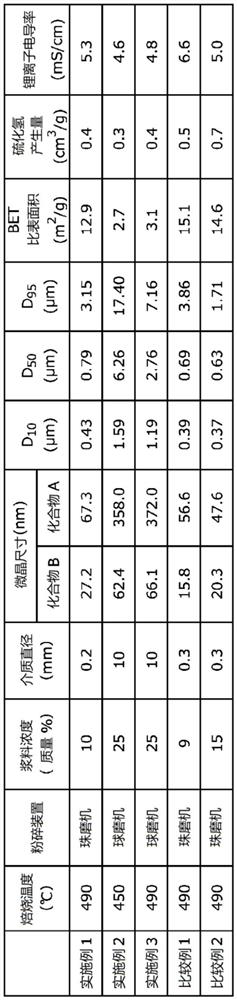

Embodiment 1

[0059] to form Li 5.4 PS 4.4 Cl 0.8 Br 0.8 way of weighing Li 2 S powder, P 2 S 5 Powder, LiCl powder and LiBr powder. These powders were pulverized and mixed using a ball mill to obtain mixed powders. The mixed powder is calcined to obtain a calcined product containing a lithium ion conductive sulfide. Firing was performed using a tubular electric furnace. During the calcination, hydrogen sulfide gas having a purity of 100% was circulated into the electric furnace at 1.0 L / min. The calcination temperature was set to 490°C, and the calcination took 4 hours. As a result of the XRD measurement, it was confirmed that the calcined product had a crystal phase of the arginite-type crystal structure and LiCl 0.5 Br 0.5 crystalline phase.

[0060] After the roasted product was roughly crushed with a mortar and pestle, it was crushed with a hammer crusher, and the crushed product was mixed with a solvent to prepare a slurry with a concentration of 10% by mass. This slurry ...

Embodiment 2

[0062] The calcination temperature, pulverizing apparatus, slurry concentration, and medium diameter in Example 1 were changed to the values shown in Table 1 below. Other than that, it carried out similarly to Example 1, and obtained the solid electrolyte.

Embodiment 3

[0064] The pulverizing apparatus, slurry concentration, and medium diameter in Example 1 were changed to the values shown in Table 1 below. Other than that, it carried out similarly to Example 1, and obtained the solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallite size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Crystallite size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com