Cu/Cr-based catalyst, preparation method thereof and application of Cu/Cr-based catalyst in preparation of 1, 2-pentanediol

A catalyst, propylene glycol technology, applied in the preparation of hydroxyl compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of dependence on imports, low catalytic activity, high cost, etc., and achieve low prices , efficient conversion, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

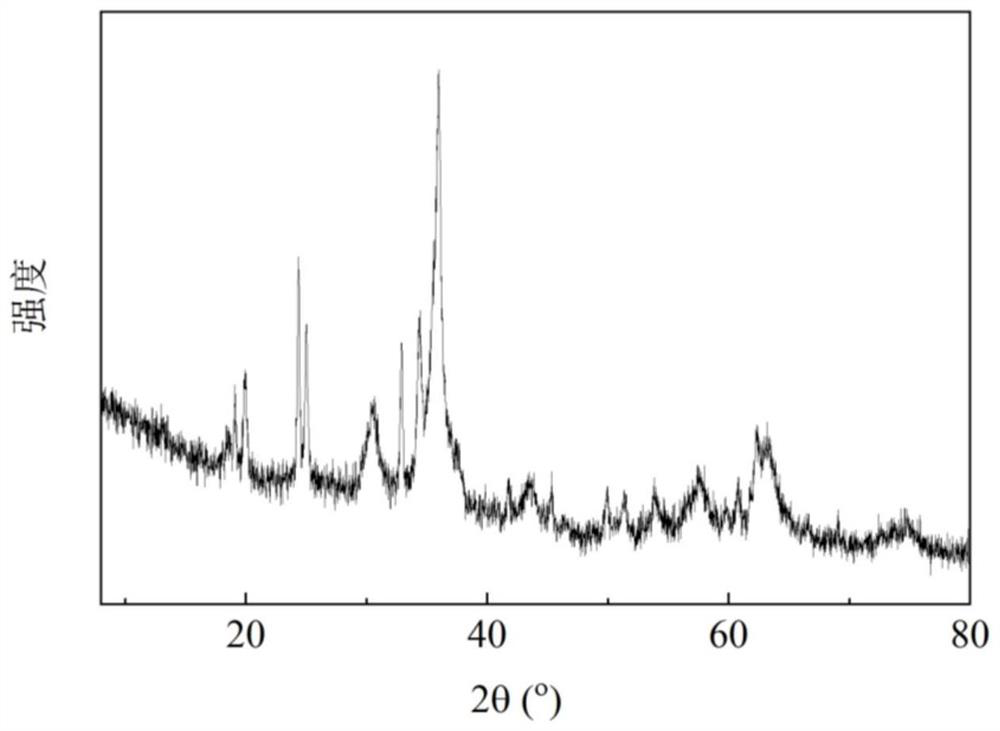

[0043] Catalyst preparation: 1) Mix copper nitrate, aluminum nitrate, and zinc nitrate into 200mL mixed solution (referred to as solution I), and the molar concentrations are 0.4mol / L, 0.2mol / L, and 0.3mol / L respectively; 2) prepare Concentration is 1.0mol / L ammonium chromate solution 150mL, add a certain volume of concentrated ammonia water, make n(NH 3 ) / n(Cr)=2 (referred to as solution II); 3) titrate solution II into solution I, and stir while titrating; 4) after titration, stir at room temperature for 1 h; 5) Suction filter and wash the obtained mixture until the filtrate becomes neutral, and dry the precipitate at 110°C for 12h; 6) Rise the dried solid to 100°C at 3°C / min in a muffle furnace After keeping at ℃ for 1h; continue to raise the temperature to 200℃ and keep for 1h; raise the temperature to 300℃ and keep for 1h; then raise the temperature to 400℃ and keep for 1h and then lower to room temperature to obtain catalyst 1, figure 1 It is the XRD pattern of catalyst...

Embodiment 2

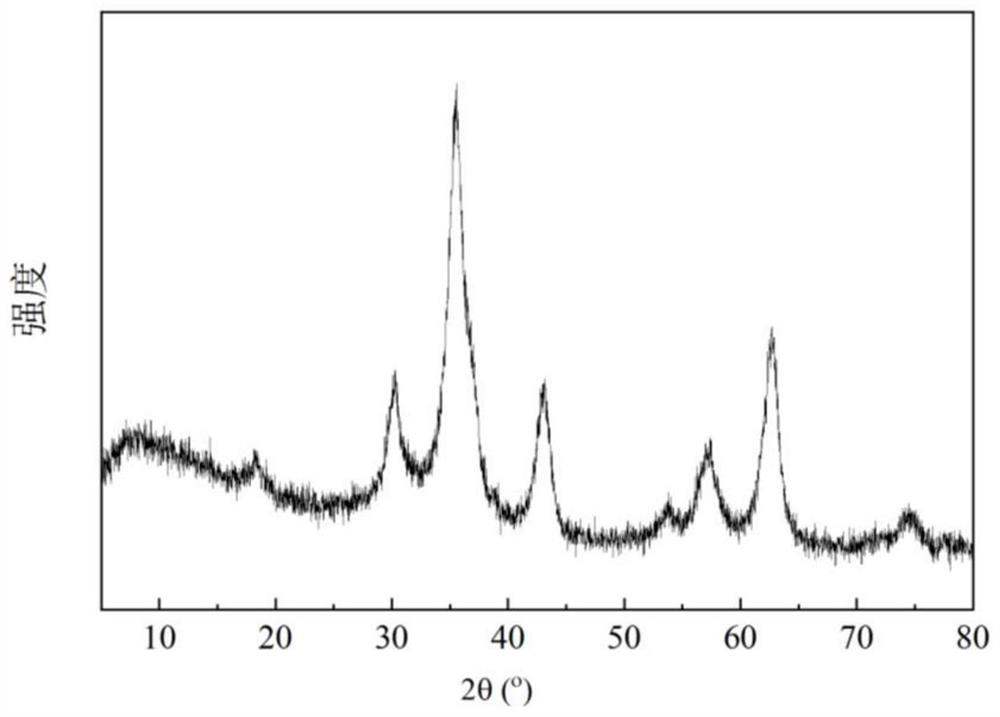

[0046] Catalyst preparation: 1) Mix copper nitrate and magnesium nitrate into 400mL mixed solution (referred to as solution I), and the molar concentrations are 0.4mol / L, 0.2mol / L, 0.1mol / L respectively; 2) The prepared concentration is 1.3 mol / L ammonium chromate solution 160mL, add a certain volume of concentrated ammonia water to make n(NH 3 ) / n(Cr)=1.8 (referred to as solution II); 3) titrate solution II into solution I, and stir while titrating; 4) after titration, stir at room temperature for 2 h; 5) Suction filter and wash the obtained mixture until the filtrate becomes neutral, and dry the precipitate at 110°C for 24h; 6) Rise the dried solid to 120°C at 2°C / min in a muffle furnace After keeping at ℃ for 1h; continue to raise the temperature to 210℃ and keep for 1h; raise the temperature to 320℃ and keep for 1h; then raise the temperature to 450℃ and keep for 3h and then cool down to room temperature to obtain catalyst 2, figure 2 It is the XRD pattern of catalyst 2....

Embodiment 3

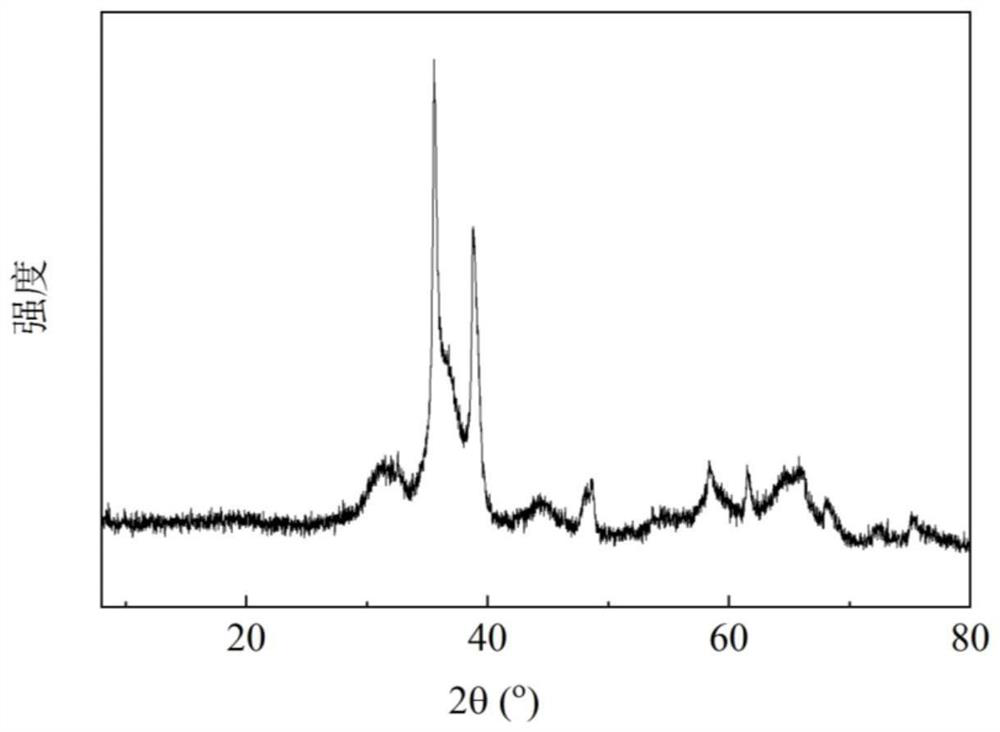

[0049] Catalyst preparation: 1) Mix copper nitrate, aluminum nitrate, and calcium nitrate into 400mL mixed solution (referred to as solution I), and the molar concentrations are 0.4mol / L, 0.2mol / L, and 0.1mol / L respectively; 2) Prepare Concentration is 1.3mol / L ammonium chromate solution 160mL, add a certain volume of concentrated ammonia water, make n(NH 3 ) / n(Cr)=1.8 (referred to as solution II); 3) titrate solution II into solution I, and stir while titrating; 4) after titration, stir at room temperature for 2 h; 5) Suction filter and wash the obtained mixture until the filtrate becomes neutral, and dry the precipitate at 110°C for 24h; 6) Rise the dried solid to 110°C at 3°C / min in a muffle furnace After keeping ℃ for 1 hour; continue to raise the temperature to 230 ℃ and keep it for 1 hour; raise the temperature to 320 ℃ and keep it for 1 hour;

[0050] Reaction evaluation: Add 20mmol 1,2-propanediol into the batch autoclave, add 15mL of ethanol, add 0.25g catalyst 3 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com