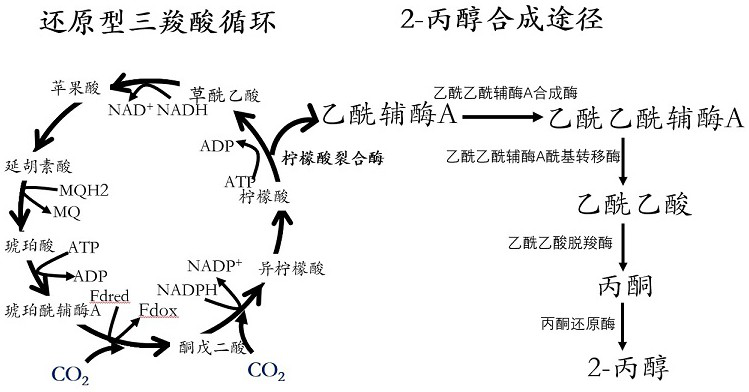

Utilize electrical energy to fix co 2 And engineering bacteria for synthesizing isopropanol and construction method

A construction method and technology for engineering bacteria, which are applied in the field of designing and constructing engineering bacteria for high-efficiency utilization of electrical energy to fix CO2 and synthesizing isopropanol, can solve the problems of high hygroscopicity, low energy density of ethanol, and corrosiveness, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The invention also provides the realization of CO by using the microbial electrosynthesis method 2 A method for synthesizing isopropanol, comprising:

[0068] The first step will carry the plasmid pRK-Geo2i-ISOPROPANOL-ISODH

[0069] of G.sulfurreducens ACL was cultured in medium to exponential growth phase (OD 600nm =0.4);

[0070] In the second step, the exponentially growing bacteria were inoculated into the cathode of the H-type microbial fuel cell with an inoculum of 10%, and the mixed gas was continuously fed into the anode to provide a carbon source for the bacterial cells.

Embodiment 1G

[0074] Example 1 G.sulfurreducens ACL chassis strain construction

[0075] Construction of pUC19-aclBA plasmid

[0076] Escherichia coli containing pUC19 plasmid E. coli Beta 10 was cultured to the mid-exponential growth period, 5 mL of bacterial solution was taken, centrifuged at 6000 × g for 5 minutes to collect the bacterial cells, the medium was discarded, and plasmid DNA was extracted according to the kit instructions. Primers PUC19-F and PUC19-R were designed according to the sequence of the foreign gene insertion site, and the plasmid fragment was amplified by DNA polymerase Q5.

[0077] According to the codon-optimized isocitrate lyase sequence and the chloramphenicol gene sequence, primers ACL-F and ACL-R and Cat-F and Cat-R were designed according to the overlap between the Gibson DNA fragments, and the synthesized gene fragments were Templates were amplified by DNA polymerase Q5 to the relevant fragments, respectively.

[0078] Will G.sulfurreducens PCA (pu...

Embodiment 2

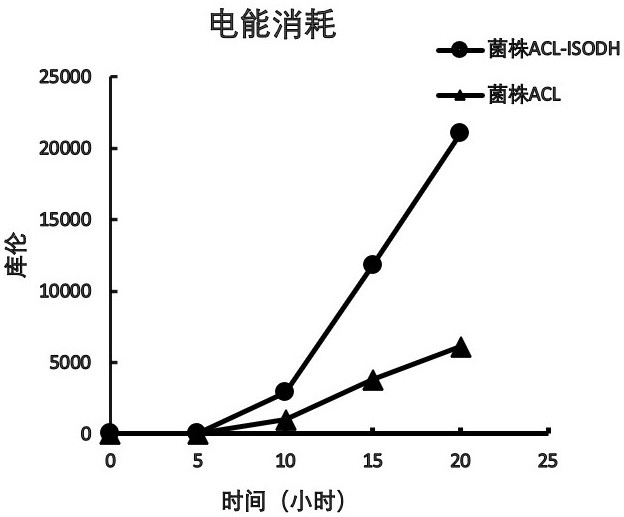

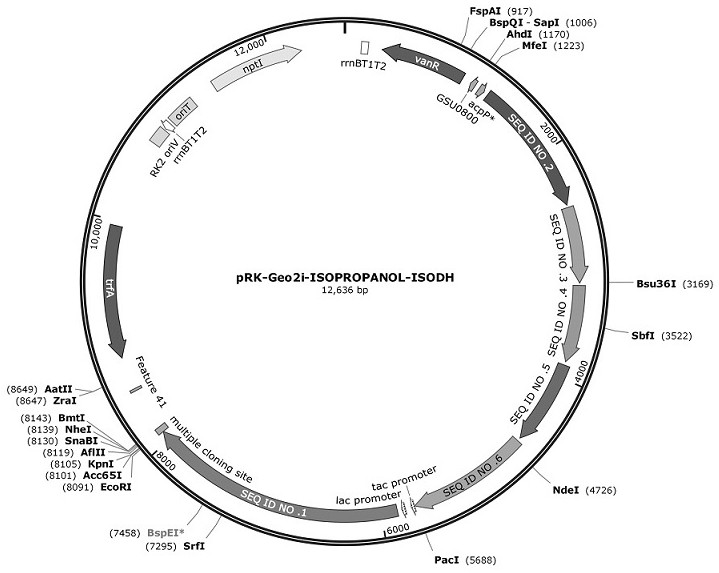

[0100] Example 2 Strain G.sulfurreducens Construction of ACL-ISODH

[0101] Construction of pRK-Geo5-ISODH plasmid

[0102] Will G.sulfurreducens The ACL original bacteria were cultured to the mid-exponential growth stage, 5 mL of bacterial liquid was taken, centrifuged at 6000 × g for 5 minutes to collect the bacterial cells, the medium was discarded, and the whole genome DNA was extracted according to the kit instructions. E. coli containing the pRK-Geo2 plasmid E. coli λS17-1 was cultured to the mid-exponential growth stage, 5 mL of bacterial liquid was taken, centrifuged at 6000 × g for 5 minutes to collect the bacterial cells, the medium was discarded, and plasmid DNA was extracted according to the kit instructions. by G.sulfurreducens ACL whole genome DNA was used as template, primers ISODH-F and ISODH-R were designed according to the sequence of isocitrate dehydrogenase, and the gene fragment was amplified by DNA polymerase Q5; Dot sequence design primers pR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com