Yoghourt oil fermented by single bacteria and preparation method thereof

A technology of sour cream and bacteria fermentation, which is applied to bacteria, lactobacillus, dairy products and other directions used in food preparation, and can solve the problems of lack of probiotic function and weak acid-producing ability of sour cream.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

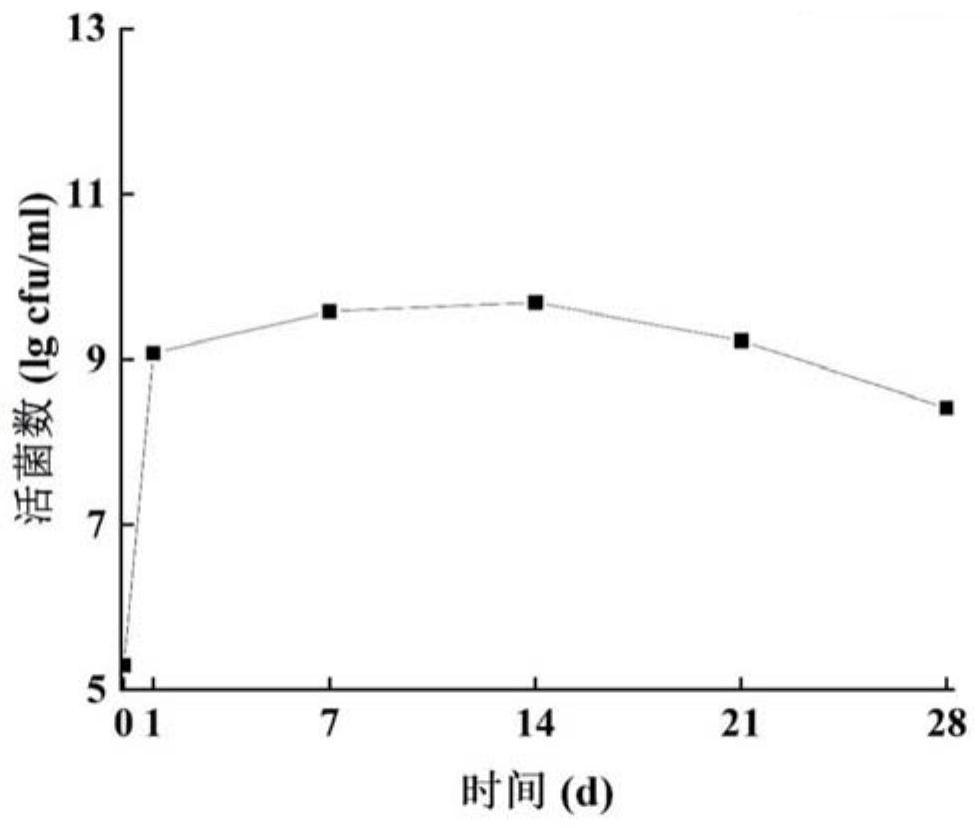

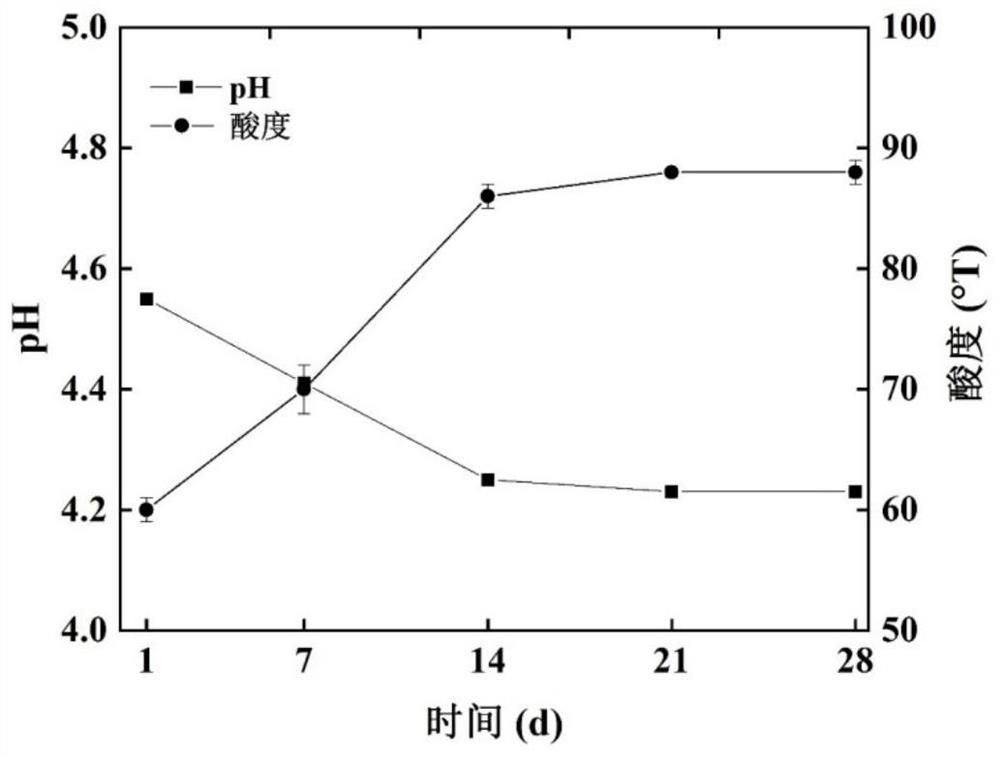

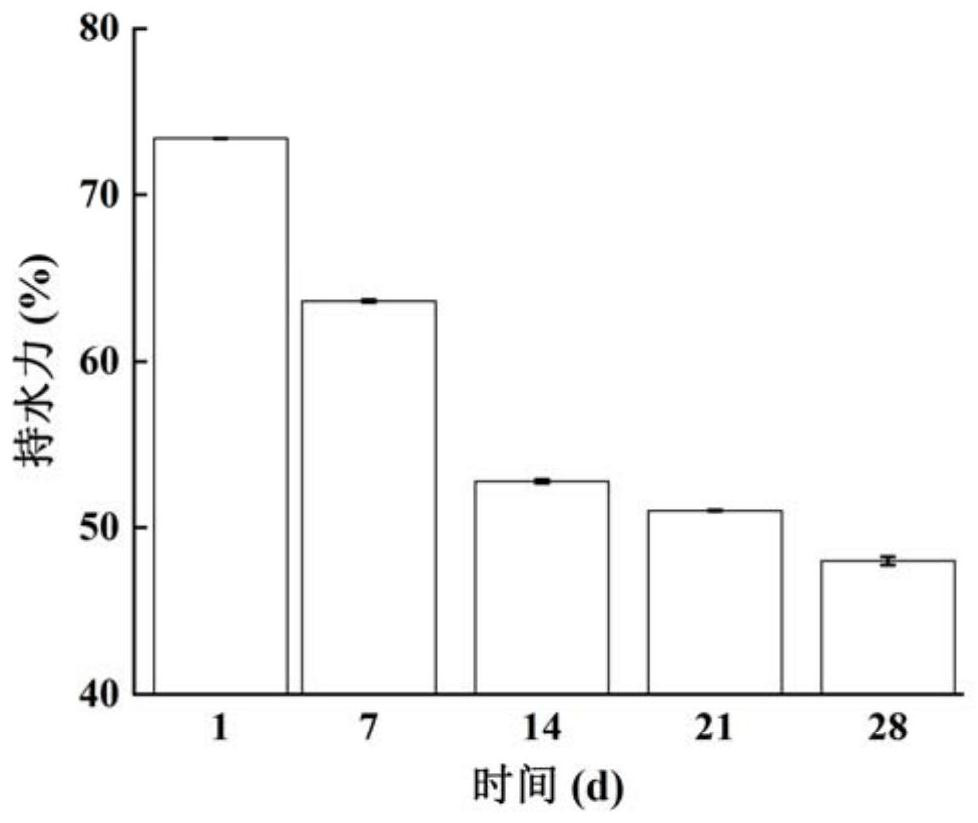

[0030] In the present invention, strain activation and cream preparation are carried out first, followed by fermentation of sour cream, and finally the determination of the number of viable cells and various indexes is completed.

[0031] The relevant medium and reagent formulations and test methods in the following examples are as follows.

[0032] 1. Experimental grease

[0033] Anjia Butter, the oil content is 82.9wt%, the specification is salt-free, and the manufacturer is New Zealand Fonterra Group.

[0034] 2. Experimental medium

[0035] MRS medium: glucose 20.0g, peptone 10.0g, anhydrous sodium acetate 5.0g, ammonium citrate 2.0g, dipotassium hydrogen phosphate 2.0g, magnesium sulfate heptahydrate 0.2g, manganese sulfate 0.05g, Tween-80 1.0ml , beef extract 10.0g, yeast extract 5.0g, water 1.0L, agar 15.0g.

[0036] 3. Main measurement methods

[0037] 1) Determination of the number of viable bacteria

[0038] Refer to GB 4789.35-2016 to determine the number of la...

Embodiment 1

[0059] 1. Strain activation

[0060] Lactobacillus delbrueckii grx601 was inoculated into MRS medium, the culture temperature was 37°C, and the fermentation was cultured for 48h.

[0061] 2. Preparation of sour cream

[0062] (1) Preparation of cream: 5% skimmed milk powder, 18% butter, 0.02% carrageenan, 1.1% sodium caseinate, 0.1% Tween 80, 0.15% soybean lecithin, 0.1% polyglycerol fatty acid ester , make up to 100% with deionized water to make cream.

[0063] (2) Homogenization and sterilization: The prepared cream was homogenized twice under a pressure of 15 MPa, and then sterilized at 85° C. for 15 minutes.

[0064] (3) Inoculation and fermentation: the material obtained in step (2) is cooled to room temperature, fermented bacteria are added at 1%, and fermented at 25° C. for 30 hours; the fermentation bacteria is Lactobacillus delbrueckii grx601.

[0065] (4) Storage: put the material obtained in step (3) into a 4°C refrigerator for refrigeration.

[0066] 3. Determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com