Method for treating low-boiling-point volatile organic contaminated soil through carbon dioxide

A volatile organic, polluted soil technology, applied in the restoration of polluted soil, air quality improvement, etc., to achieve the effect of reducing treatment costs, simple equipment, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

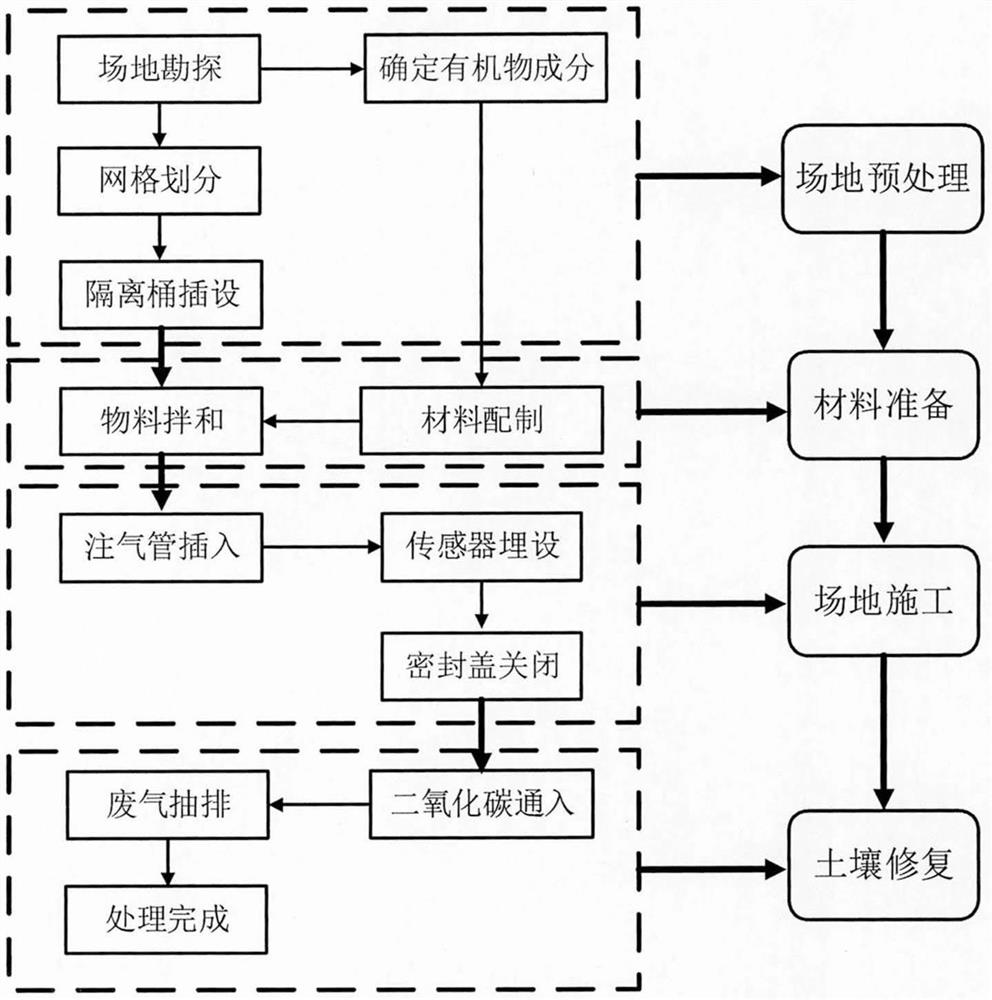

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

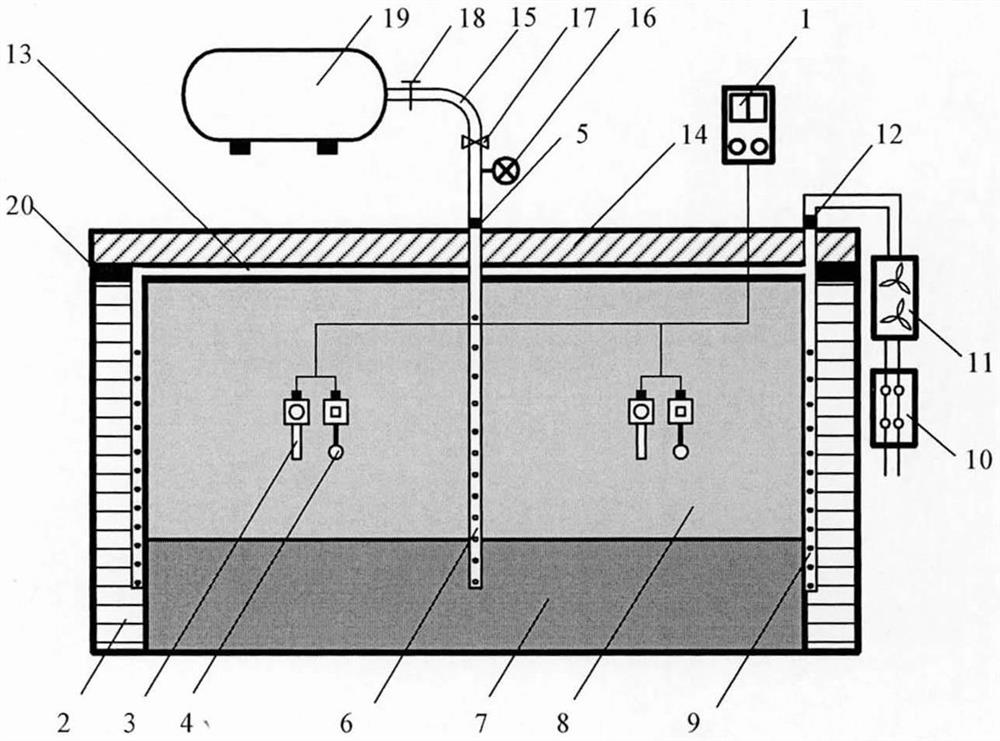

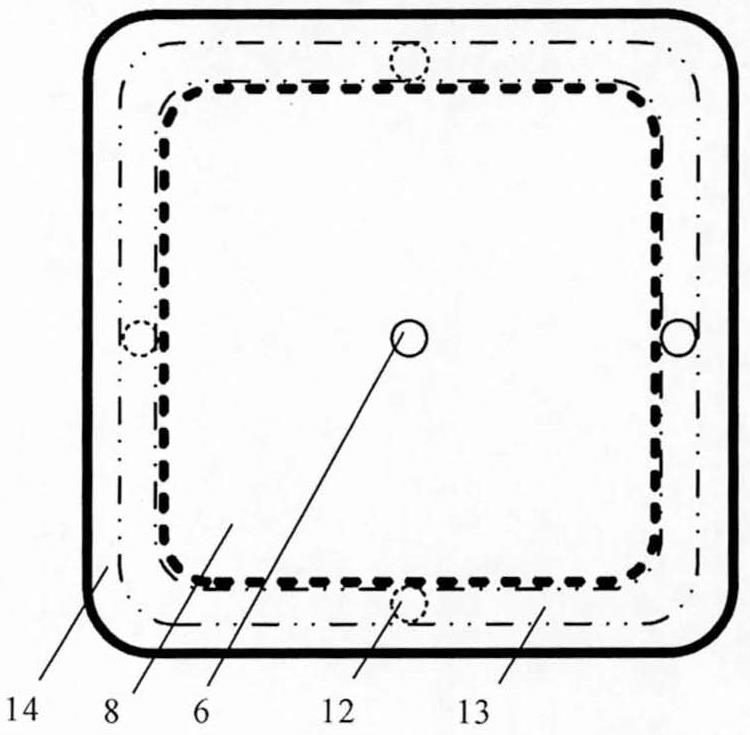

Embodiment 1

[0057] The site to be treated is the leftover site of the gas station, with a site area of 1500m2 2 , the average water content is 30%, the depth to be treated is 1m, the volatile organic compounds in the soil are mainly benzene, accounting for 70% of the total volatile organic compounds in the soil, the concentration is 60mg / kg, and the boiling point is 80.1 ℃; the site is divided into a side length of 1m The thickness of the inserted isolation barrel is 5mm, and the insertion depth is 1.3m; the configuration amount of the mixed material is 20% of the total amount of soil in the grid, and the mixed material accounts for 80 parts of active magnesium oxide and 20 parts of quicklime. The stirring time with the soil to be treated is 3 minutes; the insertion depth of the gas injection pipe is 1.1m; the sensor is buried at a depth of 0.3m below the surface, and 2 temperature sensors and 2 concentration sensors are set; after aeration, the ventilation time is 1 hour, and ventilatio...

Embodiment 2

[0059] The site to be treated is the site left over from the rubber factory, with a site area of 6000m2 2 , the average moisture content is 50%, the depth to be treated is 2m, the volatile organic compounds in the soil are mainly dichloroethane, accounting for 60% of the total volatile organic compounds in the soil, the concentration is 120 mg / kg, and the boiling point is 83.7 ℃; the site is divided into A square grid with a side length of 2m, the thickness of the inserted isolation barrel is 10mm, and the depth of insertion is 2.5m; the amount of mixed material is 30% of the total soil in the grid, and the mixed material accounts for 50 parts of active magnesium oxide and 50 parts of quicklime , the mixing time of the mixed material and the soil to be treated is 5 minutes; the insertion depth is 2.3m; the sensor is buried at a depth of 1.3m below the surface, and 4 temperature sensors and 4 concentration sensors are set; after aeration, the ventilation time is 6 hours, Vent...

Embodiment 3

[0061] The site to be treated is the leftover site of the acetylene plant, with a site area of 4000m2 2, the average moisture content is 40%, the depth to be treated is 1.5m, the volatile organic compounds in the soil are mainly 1,2-dichloroethylene, accounting for 75% of the total volatile organic compounds in the soil, the concentration is 700 mg / kg, and the boiling point is 47.67 ℃ ; The site is divided into a square grid with a side length of 1.5m, the thickness of the inserted isolation barrel is 7mm, and the depth of insertion is 1.9m; the amount of mixed material is 22% of the total soil in the grid, and the active magnesium oxide in the mixed material accounts for 20 parts , Quicklime accounts for 80 parts, and the mixing time between the mixed material and the soil to be treated is 5 minutes; the insertion depth of the gas injection pipe is 1.7m; each group of sensors is buried at a depth of 0.75m below the surface, with 3 temperature sensors and 3 concentration se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com