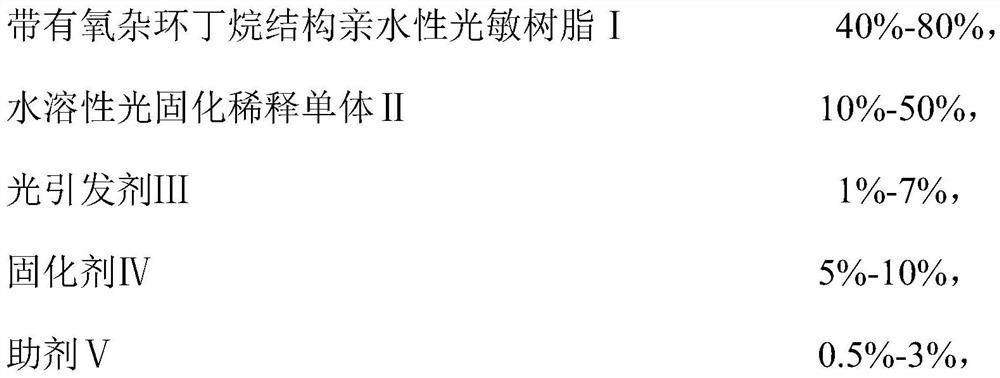

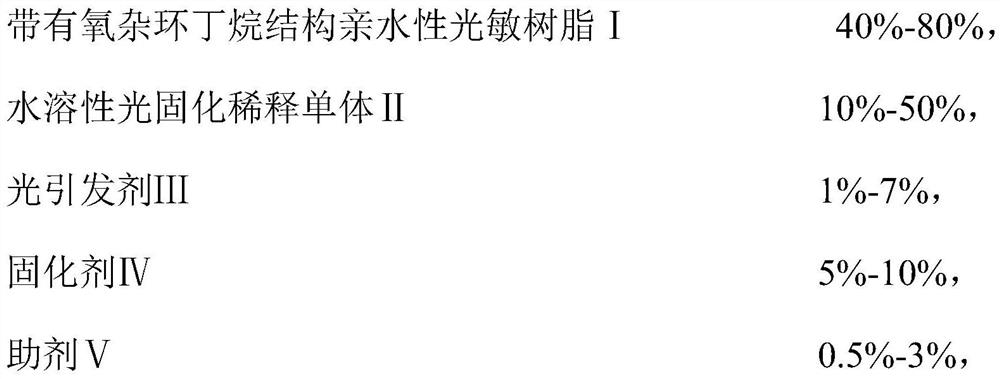

Washable 3D printing dual-curing photosensitive resin composition and preparation method thereof

A technology of resin composition and photosensitive resin, which is applied in the direction of additive processing, etc., can solve the problems of irritating odor, inconvenient operation, and failure to achieve mechanical properties, so as to increase the degree of secondary thermal curing crosslinking, improve Effect of secondary curing and improvement of washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

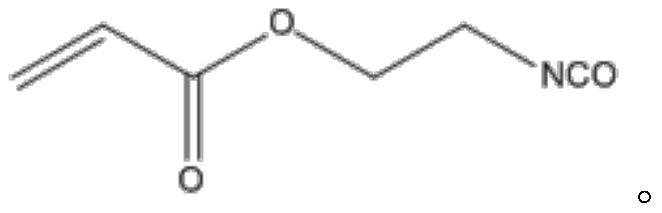

[0086] Preparation of curing agent IV-1.

[0087] 141g AOI-VM and 210.37g HMDA were added to the reaction flask equipped with a stirring device, a temperature control device and a condensing device, and the inert protective gas nitrogen was introduced, and the reaction was carried out at 60 °C for 2 hours. The measured NCO content of the prepolymer was 0.011%, the reaction was stopped to obtain curing agent IV-1.

Embodiment 2

[0089] Preparation of curing agent IV-2.

[0090] Add 141g AOI-VM and 210.37g HMDA to the reaction flask equipped with stirring device, temperature control device and condensation device, pass inert protective gas nitrogen, react at 80°C for 1.5h, and measure the NCO content of the prepolymer was 0.013%, the reaction was stopped, and curing agent IV-2 was obtained.

Embodiment 3

[0092] Preparation of curing agent IV-3.

[0093] 141g AOI-VM and 210.37g HMDA were added to the reaction flask equipped with a stirring device, a temperature control device and a condensing device, and the inert protective gas nitrogen was introduced, and the reaction was carried out at 90 °C for 1 h. The measured NCO content of the prepolymer was 0.017%, the reaction was stopped to obtain curing agent IV-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com