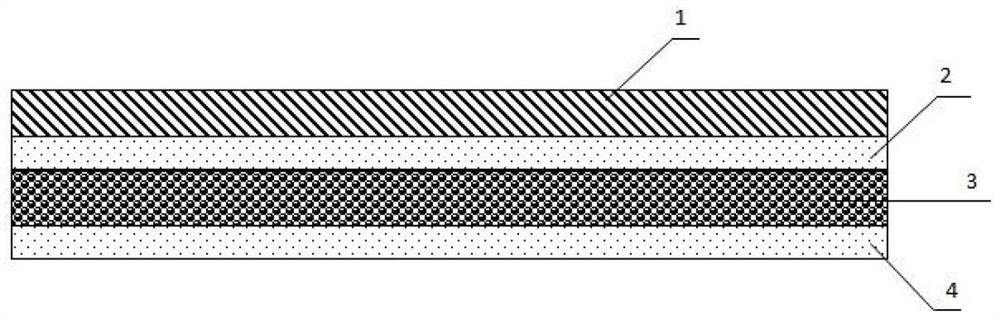

pe foam tape

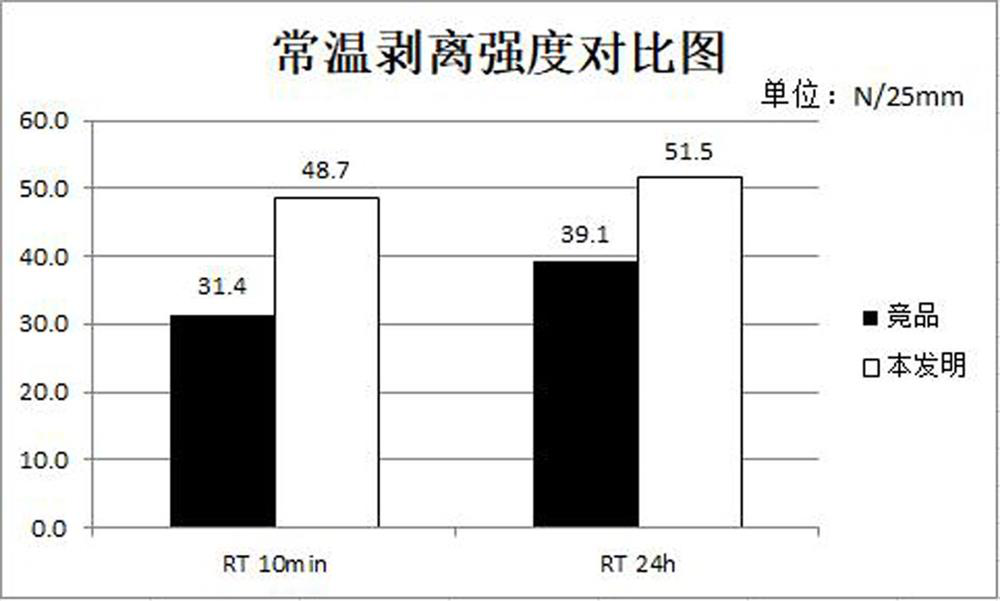

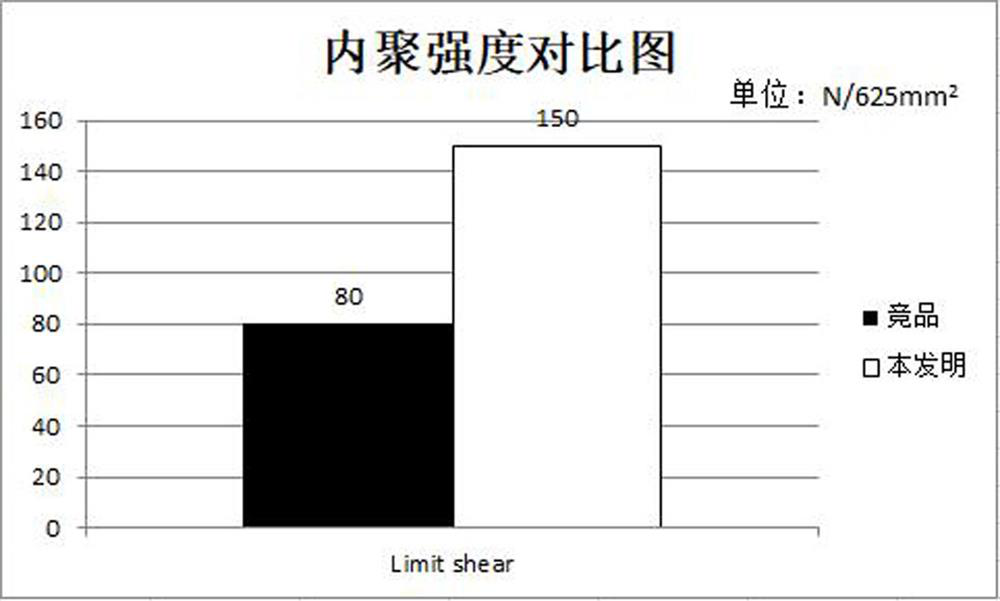

A technology of foam and tape, applied in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of low pass rate of tape reliability test, decline in overall product performance, and unreliable reliability. Guarantee and other issues to achieve the effect of ensuring application stability, increasing the difficulty of disassembly, and improving peel strength and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the adhesive is as follows: firstly, weigh the acrylate polymer solution in the glue mixing bucket, and turn on the stirrer; then weigh the tackifying resin solution and add it into the agitating glue bucket until it is evenly stirred, and finally add the crosslinking agent, Continue stirring for 30 to 50 minutes. The glue obtained after adding the cross-linking agent must be used within two hours after the stirring.

[0050] Wherein, the acrylate polymer solution is prepared by free radical polymerization in the reactor by the following components, and its composition ratio is as follows by mass percentage:

[0051] Acrylic acid (AA) 0.5~2wt%

[0052] Methyl acrylate (MA) 0.5~2wt%

[0053] 2-Hydroxyethyl acrylate (HEA) 1~2wt%

[0054] Butyl acrylate (BA) 2~10wt%

[0055] Isooctyl Acrylate (2-EHA) 30~40wt%

[0056] Azobisisobutyronitrile (AIBN) 0.05~0.2wt%

[0057] Ethyl acetate 45~60wt%.

[0058] Acrylic acid (AA) and 2-hydroxyethyl acryla...

Embodiment 1

[0085] The adhesive of the present invention includes a glue solution and a cross-linking agent, and the amount of the cross-linking agent is 1.86 wt % of the mass of the glue solution; the glue solution is a combination of an acrylate polymer solution and a tackifying resin solution , wherein the acrylate polymer solution accounts for 60wt%, and the tackifying resin solution accounts for 40wt%.

[0086] The preparation method of the adhesive is as follows: firstly, according to the formula, weigh the acrylate polymer solution in the glue mixing bucket, and turn on the stirrer; then according to the formula, weigh the tackifying resin solution and add it into the mixing glue bucket until it is evenly stirred, and finally add it. Cross-linking agent, continue to stir for 40 minutes, and the glue obtained after adding the cross-linking agent must be used within two hours after stirring.

[0087] The components and mass percentages of the acrylate polymer solution are:

[0088] ...

Embodiment 2

[0108] The performance test results of the adhesive formula and the adhesive tape are shown in Table 1, and the preparation method is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com