Stretchable organic electrochemical transistor and preparation method thereof

A transistor and chemical technology, applied in the field of stretchable organic electrochemical transistors and its preparation, can solve problems such as unsatisfactory output current and gate voltage drop, and achieve the goal of improving interface contact, increasing capacitance, and realizing low-voltage operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

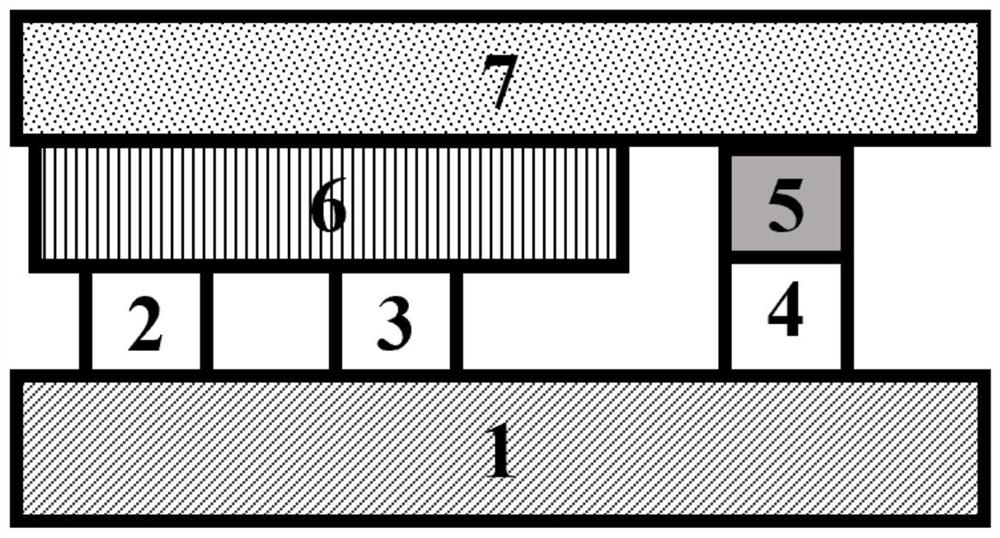

Method used

Image

Examples

Embodiment 1

[0040] Example 1 (control group):

[0041] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0042] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0043] 3. Spray the electrode (80-150nm) of carbon paste on the PU substrate;

[0044] 4. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0045]5. Spin-coat the prepared PVA solution on a microscope slide (3000rpm, 60s), and dry the spin-coated slide (110°C, 2min) to obtain a PVA sacrificial layer;

[0046] 6. Spin-coat the prepared P3HT mixed solution (P3HT:SEBS=2:1) onto the PVA sacrificial...

Embodiment 2

[0052] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0053] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0054] 3. Spray the electrode of carbon paste (80-150nm) on the PU substrate;

[0055] 4. A layer of PEDOT:PSS electrode modification layer is dripped on the gate electrode sprayed with carbon paste, and the device on which the PEDOT:PSS gate electrode modification layer is dripped is dried (30°C, 30min);

[0056] 5. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0057] 6. Spin-coat the prepared PVA solution on a microscope slide...

Embodiment 3

[0064] 1. Clean the transparent glass substrate with a surface roughness of less than 1nm, and dry it in an incubator for more than 6 hours after cleaning;

[0065] 2. Coat a layer of detergent on the glass substrate, pour the PU on the glass substrate coated with detergent, vibrate slightly, spread the solution, and place it in a vacuum drying oven to dry (30°C, 12h), carefully peel off the flexible substrate from the glass substrate with a blade after drying;

[0066] 3. Spray the electrode of carbon paste (80-150nm) on the PU substrate;

[0067] 4. A layer of PEDOT:PSS electrode modification layer is dripped on the gate electrode sprayed with carbon paste, and the device on which the PEDOT:PSS gate electrode modification layer is dripped is dried (30°C, 30min), and the above step 4 is repeated. once;

[0068] 5. Clean the microscope slides with surface roughness less than 1nm, and dry them in an incubator for more than 6 hours after cleaning;

[0069] 6. Spin-coat the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com