Lithium ion battery

A lithium-ion battery and lithium salt technology, applied in the field of lithium-ion batteries, can solve problems such as poor high-temperature performance and gas swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

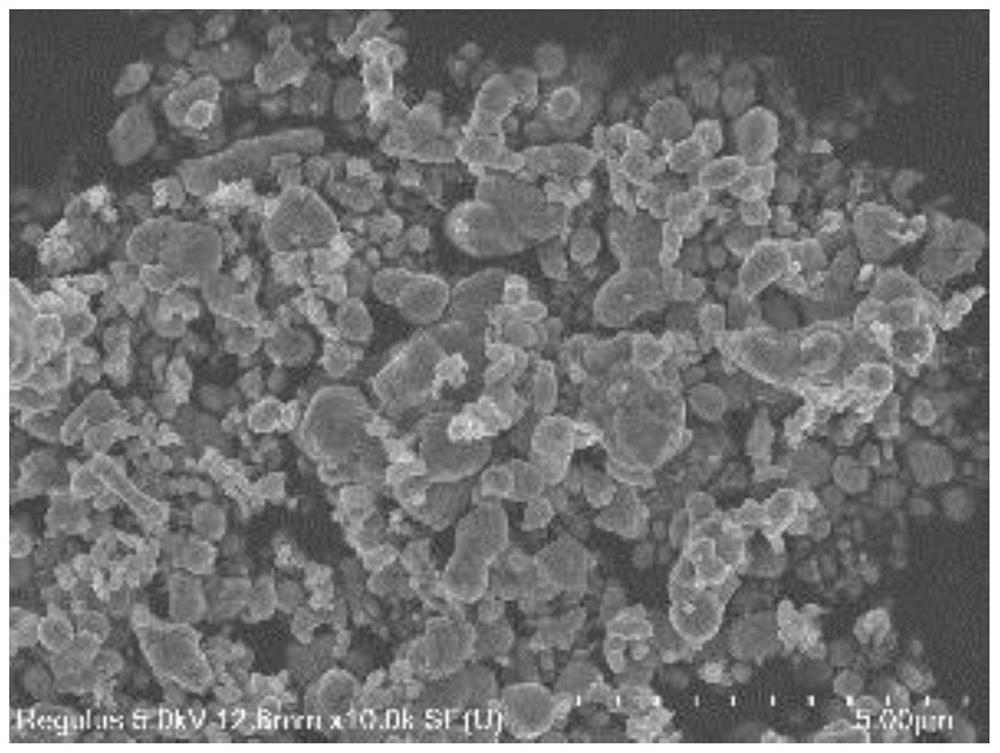

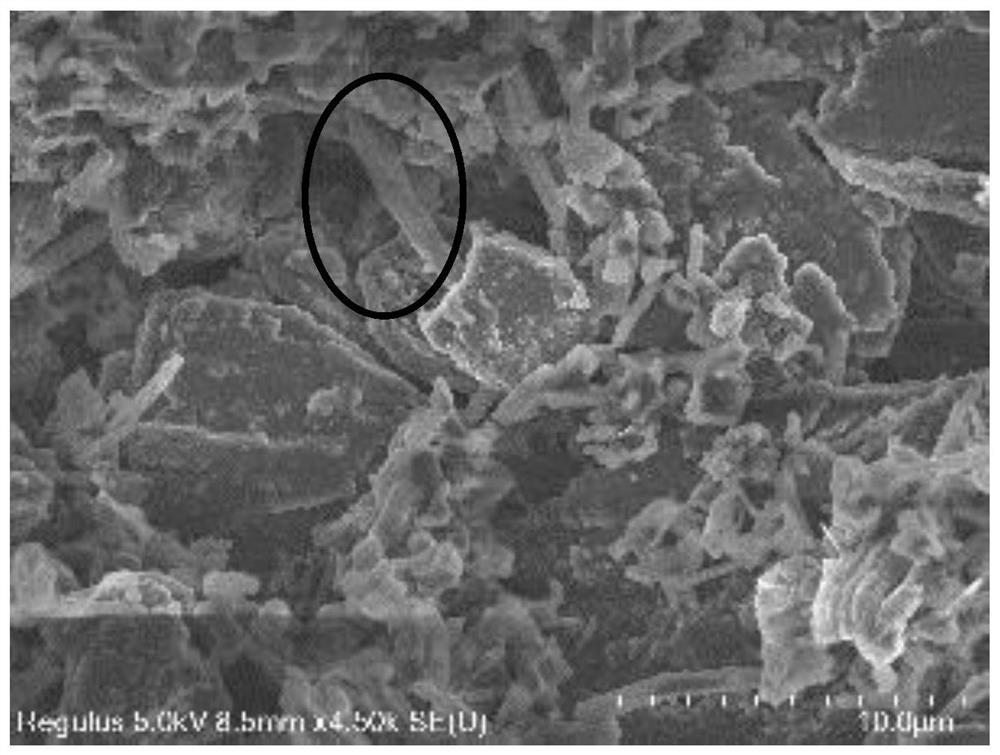

Image

Examples

Embodiment 1

[0093] 1) Preparation of electrolyte

[0094] Ethylene carbonate (EC) and ethyl methyl carbonate (EMC) were mixed in a weight ratio of EC:EMC=3:7, and then lithium hexafluorophosphate (LiPF) was added to the resulting mixture. 6 ) to the molar concentration of 1mol / L, then add compound 1 of 0.001% by weight of the total electrolyte weight (note: compound 1 here is the compound 1 in the specification, the same below) and the VC of 2% by weight of the total electrolyte weight;

[0095] 2) Preparation of positive electrode sheet

[0096] The cathode active material LiFePO 4 , Conductive agent conductive carbon black Super-P and binder polyvinylidene fluoride (PVDF) are uniformly mixed in a weight ratio of 93:4:3, and then they are dispersed in N-methyl-2-pyrrolidone (NMP) , to obtain the positive electrode slurry; the positive electrode slurry is evenly coated on both sides of the aluminum foil, dried, calendered (compacted density is shown in Table 1) and vacuum dried, and the...

Embodiment 2-18 and comparative example 1-8

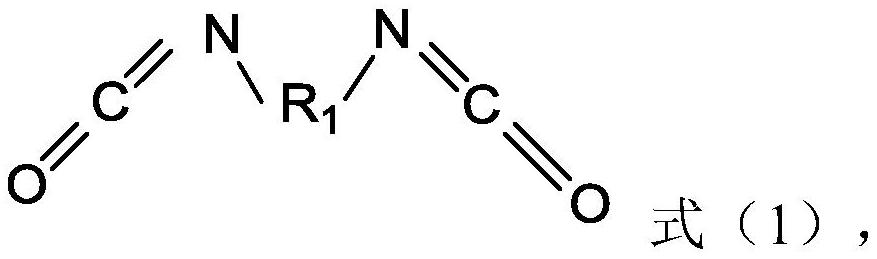

[0104] Follow the method of Example 1, except that the compaction density of the positive and negative electrode materials of the lithium ion battery, the type and addition amount of the compound represented by formula (1) added to the electrolyte, the addition amount of VC, and other additives The type and the amount of added are different, and the specific content is shown in Table 1.

[0105] Table 1

[0106]

[0107] Note: / means no corresponding substance added, LiPO 2 F 2 It is lithium difluorophosphate, DTD is vinyl sulfate, and MMDS is methylene methane disulfonate.

[0108] The relevant properties of the lithium ion batteries prepared in Examples 1-18 and Comparative Examples 1-8 are shown in Table 2.

[0109] Table 2

[0110]

[0111] It can be seen from the results of the above Examples 1-9 and Comparative Example 1 that the positive electrode active material LiFePO of the present invention is used 4 , within the range of the compaction density of the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com