Low negative pressure injection deep hole continuous sampling system and sampling method

A sampling system, low negative pressure technology, applied in the direction of earthwork drilling, wellbore/well components, gas discharge, etc., can solve the problem of large gas analysis loss, etc., and achieve the effect of saving operation time, convenient operation, and low flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

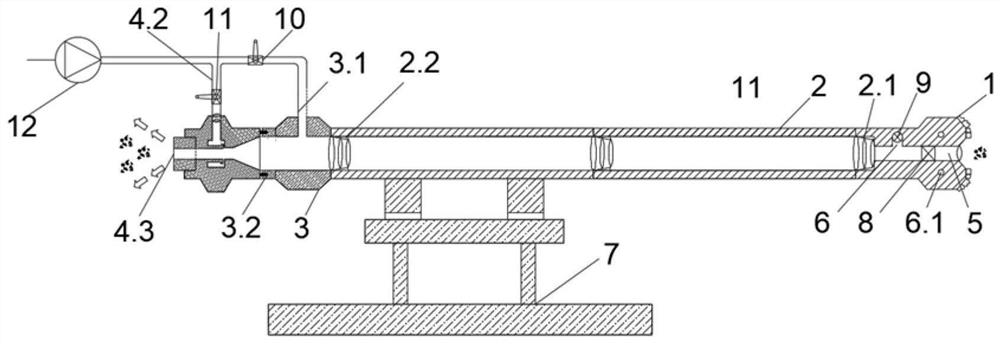

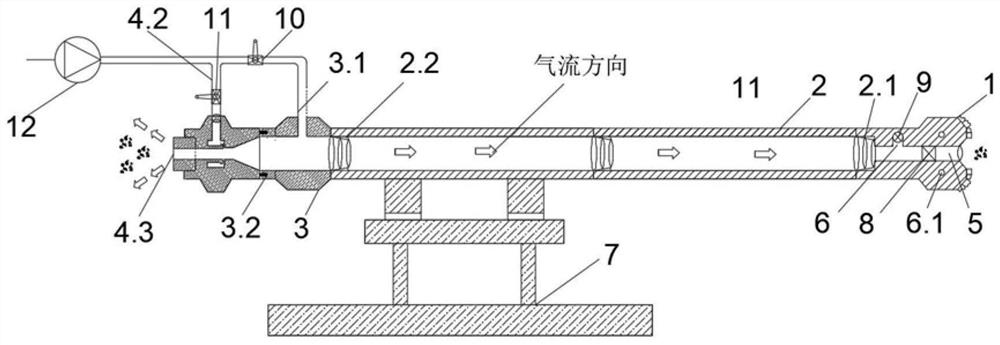

Method used

Image

Examples

Embodiment

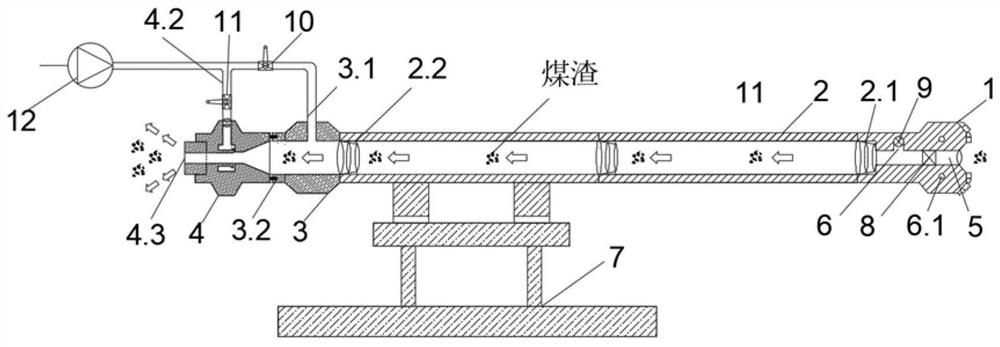

[0108] ①When the sampling drill bit 1 drills to the sampling point A, close the manual valve I10, open the manual valve II11, the air supply pump 12 provides compressed air flow, and the compressed air flows through the air supply pipeline 4.2 to the compressed air inlet 4.1 and then flows to the air amplifier 4 Negative pressure air flow is formed inside, compressed air volume Q 缩 is 100L / min, the diameter d of the exhaust slag discharge port of the air amplifier 4 is 4.3 出 0.1m, the air inlet of the air amplifier is 4.4 in diameter d 进 is 0.15m, the Q measured by the downhole field test 出 for Q 缩 20 times as 2×10 4 L / min, the n value is equal to 10, the airflow velocity v of the exhaust slag discharge port 4.3 出 4.24×10 3 m / s;

[0109] ②Under the action of the air amplifier 4, a negative pressure environment is formed in the drill pipe 2, and the negative pressure airflow flows into the sampling hole 5 of the sampling drill bit 1. Under the action of the negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com