Chemical scale removing method for evaporator

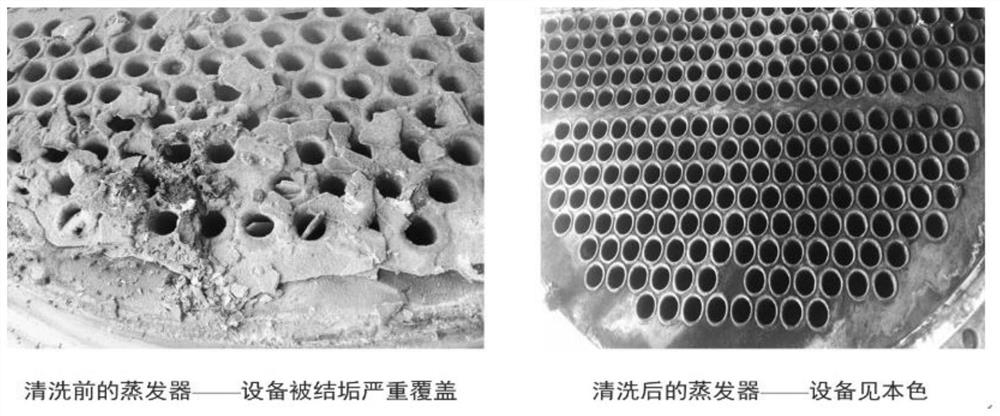

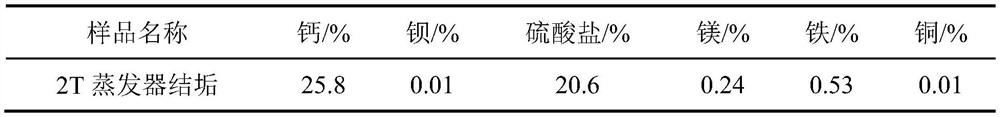

An evaporator and chemical technology, which is applied in the field of chemical descaling of evaporators, can solve the problems of insufficient cleaning, time-consuming and labor-intensive, and scaling of three-effect evaporators, so as to avoid heat dissipation problems, reduce descaling time, and shorten cleaning time. The effect of the fouling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

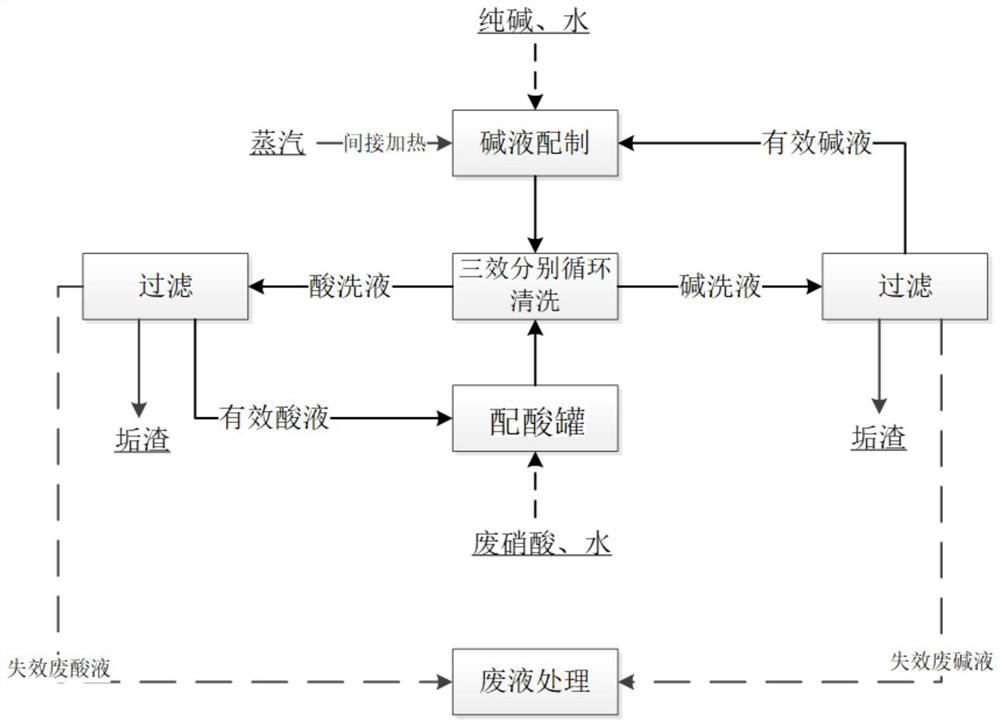

[0057] The evaporator cleaning process can be summarized as the following steps:

[0058] (1) prepare the sodium carbonate solution of 20wt% concentration in proportion in the dispensing tank, and heat the lye to 60 ℃ by steam; prepare the nitric acid solution of 10wt% concentration at normal temperature (25 ℃) in the acid dispensing tank;

[0059](2) The sodium carbonate solution is pumped into the first-effect, second-effect, and third-effect separators respectively through three feed pumps, and circulating cleaning is carried out separately in the three evaporation systems, and the cleaning temperature is controlled at 65 ° C, and the cleaning The sodium carbonate solution used during cleaning accounts for 55% of the volume of the cleaning container;

[0060] (3) After 30min of circulation, the sodium carbonate solution in the triple-effect evaporator is simultaneously discharged into the lye filter tank for filtration through the discharge pipe, and the filtrate is returne...

Embodiment 2

[0065] The evaporator cleaning process can be summarized as the following steps:

[0066] (1) the sodium carbonate solution of 15wt% concentration is prepared in proportion in the dispensing tank, and the lye is heated to 60 ℃ by steam; the nitric acid solution of 3wt% concentration is prepared at normal temperature (25 ℃) in the acid dispensing tank;

[0067] (2) The sodium carbonate solution is pumped into the first-effect, second-effect, and third-effect separators respectively through three feed pumps, and circulating cleaning is carried out separately in the three evaporation systems, and the cleaning temperature is controlled at 70 ° C, and the cleaning The sodium carbonate solution used during cleaning accounts for 60% of the volume of the cleaning container;

[0068] (3) After 30min of circulation, the sodium carbonate solution in the triple-effect evaporator is simultaneously discharged into the lye filter tank for filtration through the discharge pipe, and the filtra...

Embodiment 3

[0073] The evaporator cleaning process can be summarized as the following steps:

[0074] (1) prepare the sodium carbonate solution of 25wt% concentration in proportion in the dispensing tank, and heat the lye to 70 ℃ by steam; prepare the nitric acid solution of 6wt% concentration at normal temperature (25 ℃) in the acid dispensing tank;

[0075] (2) The sodium carbonate solution is pumped into the first-effect, second-effect, and third-effect separators respectively through three feed pumps, and circulating cleaning is carried out separately in the three evaporation systems, and the cleaning temperature is controlled at 75 ° C, and the cleaning The sodium carbonate solution used during cleaning accounts for 65% of the volume of the cleaning container;

[0076] (3) After 30min of circulation, the sodium carbonate solution in the triple-effect evaporator is simultaneously discharged into the lye filter tank for filtration through the discharge pipe, and the filtrate is returne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com