Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery comprising same

A non-aqueous electrolyte, lithium secondary battery technology, applied in non-aqueous electrolyte batteries, secondary batteries, electrolytes, etc., can solve the problems of high-temperature storage characteristics degradation of secondary batteries, inability to be effectively charged, etc., to improve high-temperature storage. Characteristics and capacity characteristics, reduction of battery swelling, effect of suppressing gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] (Preparation of non-aqueous electrolyte solution)

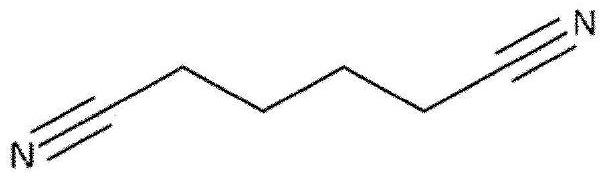

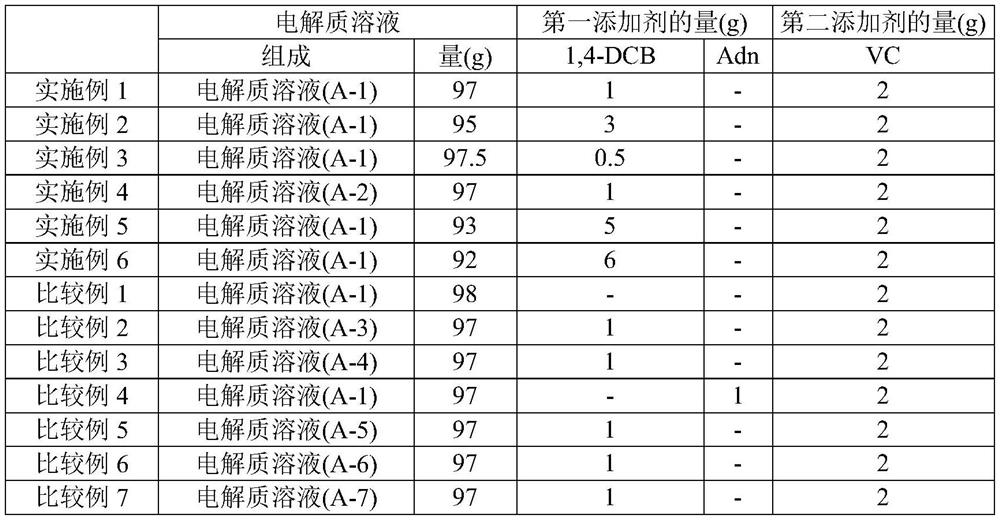

[0128] Ethylene carbonate and ethyl propionate are mixed in a volume ratio of 1:9 and then LiPF is dissolved 6 Make LiPF 6 the concentration is 1.6 M, from which an electrolyte solution (A-1) is prepared. 1 g of 1,4-dicyanobutene and 2 g of vinylene carbonate were added as additives to 97 g of electrolyte solution (A-1) to prepare a non-aqueous electrolyte solution (B-1).

[0129] (Preparation of electrode assembly)

[0130] The positive electrode active material (LiCoO 2), conductive agents (carbon black) and adhesives (polyvinylidene fluoride; PVDF) was added as a solvent in n-methyl-2-pyrrolidinone (NMP) as a solvent in a 94:3:3 weight ratio to prepare a cathode slurry. A film of approximately 20 μm thick aluminum (Al) that is used as a cathode collector is coated with a cathode slurry, dried, and then rolled to prepare the positive electrode.

[0131] The negative electrode active material (graphite), conductive agent ...

Embodiment 2

[0136] 3g of 1,4-dicyanobutene and 2g of vinylene carbonate were added to 95g of electrolyte solution (A-1) to prepare a non-aqueous electrolyte solution of the present invention (B-2).

[0137] Subsequently, a pouch type lithium secondary battery is prepared in the same manner as Example 1, the difference is that a non-aqueous electrolyte solution (B-2) is injected instead of a non-aqueous electrolyte solution of Example 1 (B-1).

Embodiment 3

[0139] 0.5g of 1,4-dicyanobutene and 2g of vinylene carbonate were added to 97.5g of electrolyte solution (A-1) to prepare a non-aqueous electrolyte solution of the present invention (B-3).

[0140]Subsequently, a pouch type lithium secondary battery is prepared in the same manner as Example 1, the difference is that a non-aqueous electrolyte solution (B-3) is injected instead of a non-aqueous electrolyte solution (B-1) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com