Multi-cavity microsphere based on electronic injection method and preparation method of multi-cavity microsphere

A multi-chamber and microsphere technology, which is used in the preparation of microspheres, microcapsule preparations, medical preparations with inactive ingredients, etc. Due to the limited capacity of the centrifuge tube, the effect of strengthening the protection and confinement effect, improving the protection and confinement effect, and the preparation device is simple and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A multi-chamber microsphere based on electrospray method, which can form microspheres with core-shell structure in one step. Its preparation method comprises the following steps:

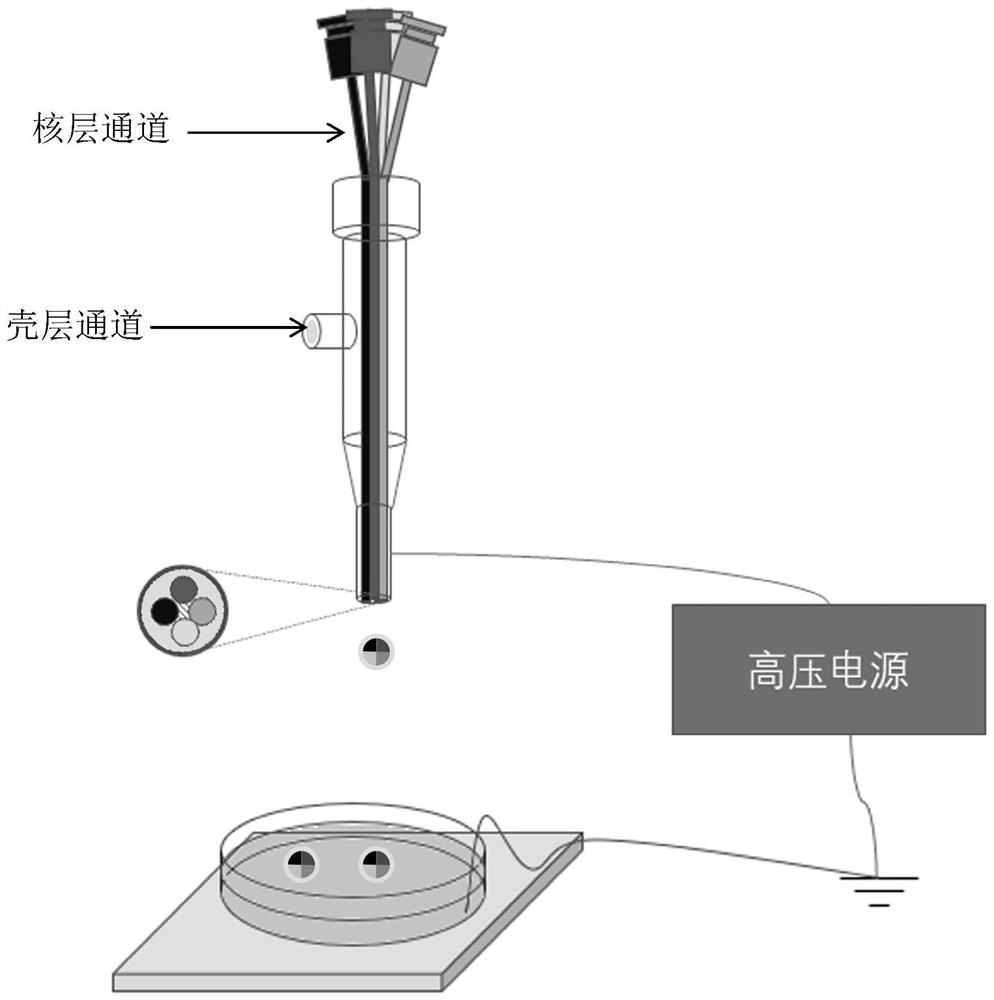

[0031] (1) Making coaxial needles: Two 30G metal flat needles are arranged in parallel in the same direction and fixed with quick-drying glue. The above-mentioned fixed coaxial needle is passed through the T-shaped tee, the penetration port is closed with a rubber cap, and a 19G needle is externally connected to the penetration port, which communicates with the side hole of the tee to form a shell channel. Keep all needle tips flush. The coaxial needle includes a core layer channel and a shell layer channel, and the entrance of the shell layer channel is located on the side of the coaxial needle and is perpendicular to the core layer channel; the core layer channel includes two channels, and each channel is distributed in parallel.

[0032] (2) Dissolve sodium alginate in deionized water at...

Embodiment 2

[0036] A multi-chamber microsphere based on electrospray method, which can form a three-chamber microsphere with a core-shell structure in one step. Its preparation method comprises the following steps:

[0037] (1) Making coaxial needles: Three 30G metal flat needles are used in close parallel arrangement in the same direction, the cross-section is triangular, and the quick-drying glue is fixed. The above-mentioned fixed coaxial needle is passed through the T-shaped tee, the penetration port is closed with a rubber cap, and a 19G needle is externally connected to the penetration port, which communicates with the side hole of the tee to form a shell channel. Keep all needle tips flush. The coaxial needle includes a core layer channel and a shell layer channel, and the entrance of the shell layer channel is located on the side of the coaxial needle and is perpendicular to the core layer channel; the core layer channel includes three channels, and each channel is distributed in...

Embodiment 3

[0042] An electrospray-based multi-chamber microsphere, which can form four-chamber microspheres with a core-shell structure (such as figure 1 shown). Its preparation method comprises the following steps:

[0043] (1) Making coaxial needles: Four 30G metal flat needles are arranged in parallel in the same direction and fixed with quick-drying glue. The above coaxial needle is passed through the T-shaped tee, the penetration port is closed with a rubber cap, and an 18G needle is externally connected to the penetration port, which communicates with the side hole of the tee to form a shell channel. Keep all needle tips flush. The coaxial needle includes a core layer channel and a shell layer channel, and the entrance of the shell layer channel is located on the side of the coaxial needle and is perpendicular to the core layer channel; the core layer channel includes 4 channels, and each channel is distributed in parallel.

[0044] (2) Dissolve sodium alginate in deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com