Water retention material for preventing water and soil loss and preparation method thereof

A technology of water-retaining materials and degradable materials, which is applied in the field of water and soil conservation, can solve the problems of slow treatment process, large investment and labor, and achieve the effect of simple preparation process, fast speed and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

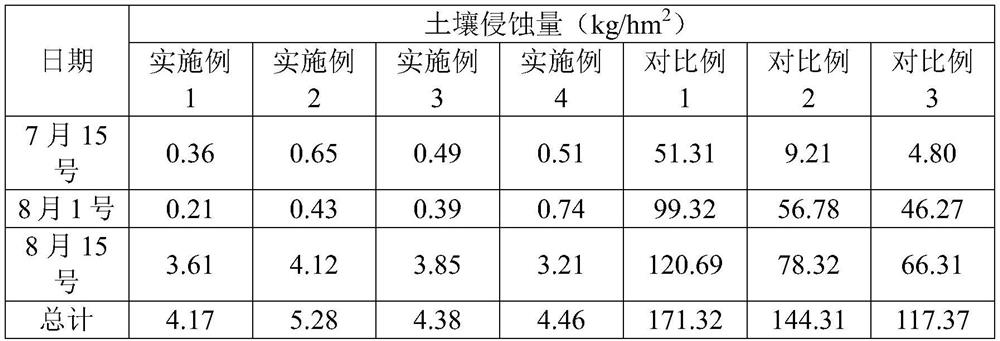

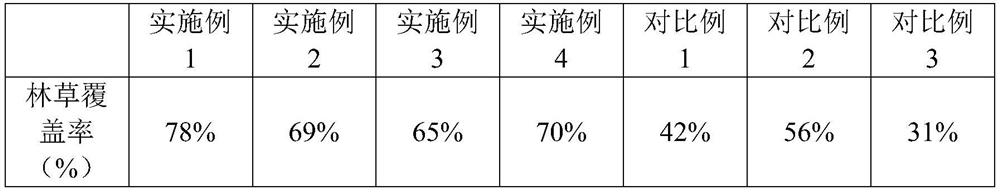

Examples

Embodiment 1

[0029] (1) Pulverize the straw fibers to a length of 4 mm, grind ceramics and quartz sand to a mesh number of 120, and weigh 18 parts of straw fibers, 12 parts of ceramics, 8 parts of fly ash, 5 parts of organic fertilizer, 12 parts of super absorbent resin, 6 parts of seeds (arbitrary proportions of Cinnamon chinensis seeds, Leymus chinensis seeds, Sandyweed seeds, Alkali grass seeds) and 5 parts of quartz sand, mixed evenly in an inclined mixing granulator Granulation to prepare composite inorganic spheres with a particle size of 0.8 cm;

[0030] (2) Take a degradable PLA mesh or a degradable PP mesh with a mesh aperture of 4 mm and a thickness of 0.3 mm, cut it into a square with a side length of 1 m, and apply a layer of thickness to the surface of the degradable PLA mesh or degradable PP mesh. The adhesive layer is guar gum, carrageenan or konjac gum with a thickness of 0.2 mm. Immediately after painting, the composite inorganic spheres prepared in step (1) are evenly spr...

Embodiment 2

[0032] (1) pulverize the straw fibers to a length of 5 mm, grind ceramics and quartz sand to a mesh number of 150, and weigh 20 parts of straw fibers, 18 parts of ceramics, 10 parts of fly ash, 6 parts of organic fertilizer, 12 parts of super absorbent resin, 5 parts of seeds (arbitrary proportions of C. chinensis seeds, Leymus chinensis seeds, and 3 parts of quartz sand), mixed evenly and granulated in an inclined mixing granulator to prepare a Composite inorganic spheres with a particle size of 0.5cm;

[0033] (2) Take a degradable PLA mesh or a degradable PP mesh with a mesh aperture of 3 mm and a thickness of 1 mm, cut it into a square with a side length of 1 m, and apply a layer of thickness to the surface of the degradable PLA mesh or degradable PP mesh. 0.2mm adhesive layer of guar gum, carrageenan or konjac gum, immediately after brushing, evenly spread the composite inorganic spheres prepared in step (1) on the surface of the adhesive layer, so that the dosage of comp...

Embodiment 3

[0035] (1) pulverize the straw fibers to a length of 5 mm, grind ceramics and quartz sand to a mesh number of 100, and weigh 15 parts of straw fibers, 5 parts of ceramics, 5 parts of fly ash, 3 parts of organic fertilizer, 12 parts of super absorbent resin, 8 parts of seeds (arbitrary proportions of C. chinensis seeds and Leymus chinensis seeds) and 7 parts of quartz sand were mixed evenly and granulated in an inclined mixing granulator to prepare a compound with a particle size of 1 cm. inorganic spheres;

[0036](2) Take a degradable PLA mesh or a degradable PP mesh with a mesh aperture of 5 mm and a thickness of 0.15 mm, cut it into a square with a side length of 1 m, and apply a layer of thickness to the surface of the degradable PLA mesh or degradable PP mesh. The adhesive layer is guar gum, carrageenan or konjac gum with a thickness of 0.2 mm. Immediately after painting, the composite inorganic spheres prepared in step (1) are evenly spread on the surface of the adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com