Method for improving near-infrared fluorescence intensity of bismuth-doped quartz glass

A quartz glass, fluorescence intensity technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of weak fluorescence intensity, uneven fluorescence peak shape, low luminous efficiency, etc., to increase the number and increase the communication wavelength. range, the effect of promoting near-infrared luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

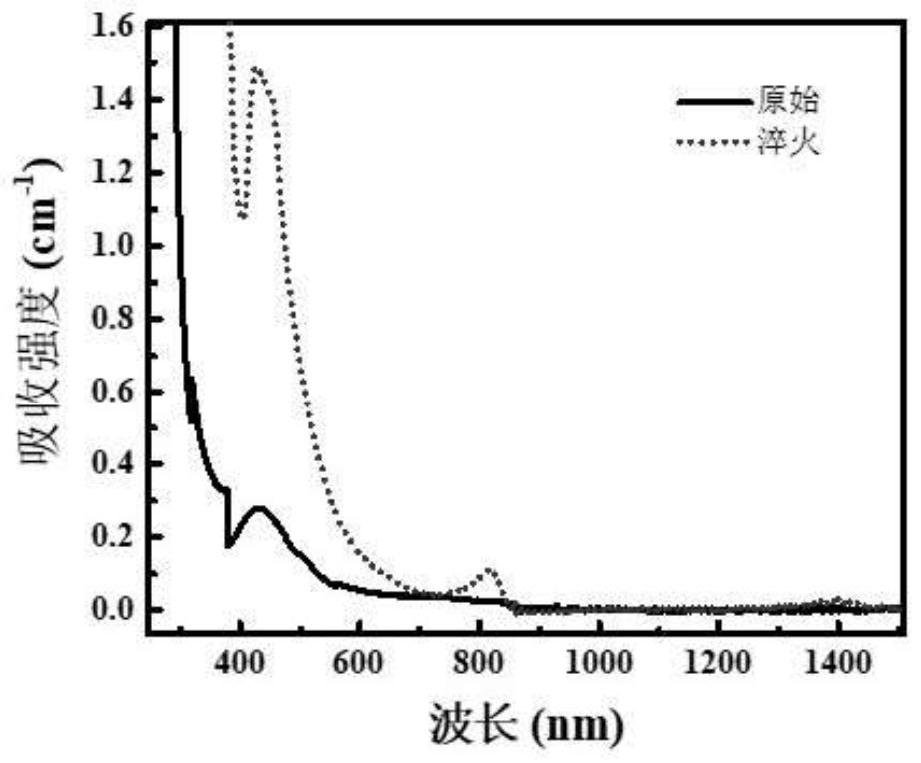

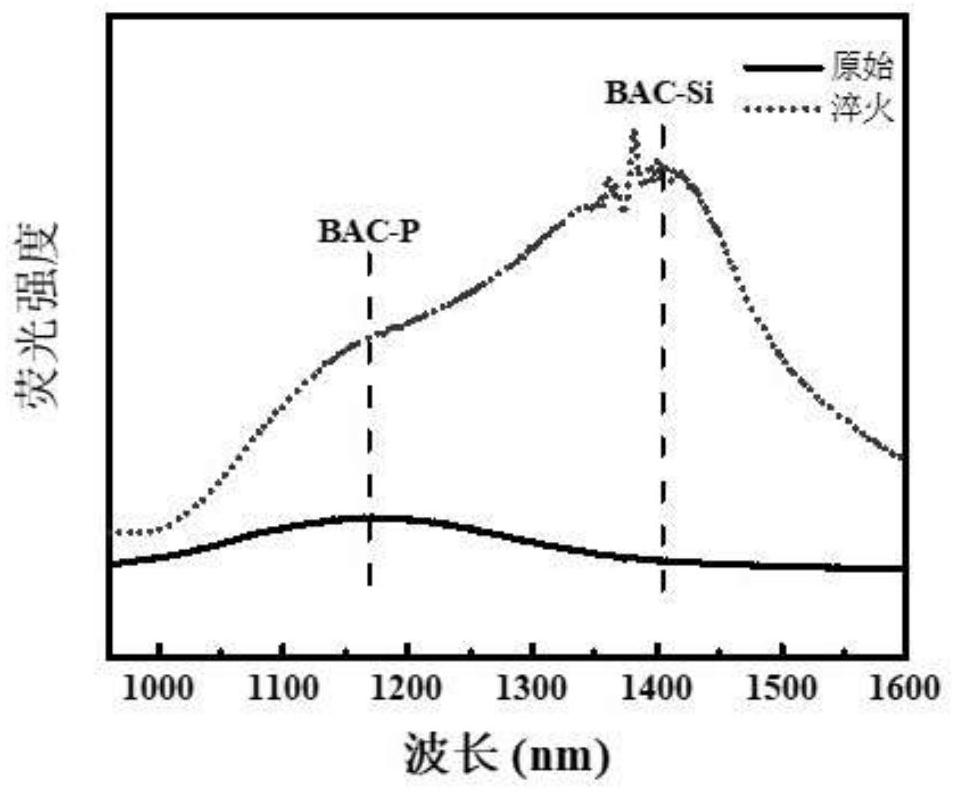

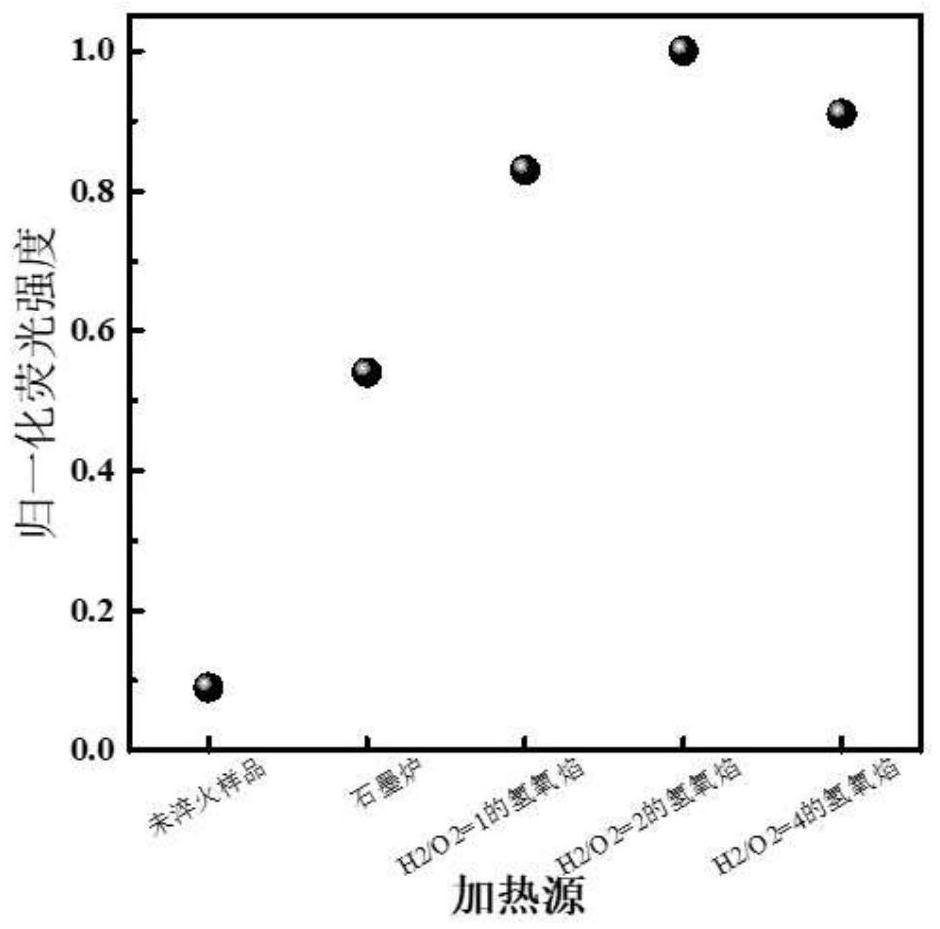

[0028] Example 1: (see figure 1 , figure 2 , image 3 and table 1)

[0029] The composition (molar percentage) of the Bi / P co-doped quartz glass in this embodiment is: 0.1Bi 2 O 3 -10P 2 O 5 -89.9SiO 2 .

[0030] The quenching process of Bi / P co-doped quartz glass includes:

[0031] (1) Clean the glass surface with acetone or alcohol first to avoid the introduction of impurities during high temperature heat treatment;

[0032] (2) The bismuth-doped quartz glass is welded on the end face of one side of the pure quartz glass tube. via H 2 / O 2 The oxyhydrogen flame of =1 is heated to the molten state of 1600-1800 ℃;

[0033] (3) The bismuth-doped quartz glass in the molten state is rapidly placed in deionized water at 25°C and completely soaked, and then rapidly quenched;

[0034] (4) The quenched sample is taken out, processed into a predetermined size, polished on both sides, and then cleaned and dried.

[0035] Test results such as figure 1 and figure 2 show...

Embodiment 2

[0036] Example 2: (see figure 1 , figure 2 , image 3 and table 1)

[0037] The composition (molar percentage) of the Bi / P co-doped quartz glass in this embodiment is: 0.1Bi 2 O 3 -10P 2 O 5 -89.9SiO 2 .

[0038] The quenching process of Bi / P co-doped quartz glass includes:

[0039] (1) Clean the glass surface with acetone or alcohol first to avoid the introduction of impurities during high temperature heat treatment;

[0040] (2) The bismuth-doped quartz glass is welded on the end face of one side of the pure quartz glass tube. It is heated to a molten state of 1600-1800 ℃ by a graphite furnace;

[0041] (3) The bismuth-doped quartz glass in the molten state is rapidly placed in deionized water at 25°C and completely soaked, and then rapidly quenched;

[0042] (4) Take out the quenched sample, process it into a predetermined size, polish both sides, and then clean and dry

Embodiment 3

[0043] Example 3: (see figure 1 , figure 2 , image 3 and table 1)

[0044] The composition (molar percentage) of the Bi / P co-doped quartz glass in this embodiment is: 0.1Bi 2 O 3 -10P 2 O- 5 89.9SiO 2 .

[0045] The quenching process of Bi / P co-doped quartz glass includes:

[0046] (1) Clean the glass surface with acetone or alcohol first to avoid the introduction of impurities during high temperature heat treatment;

[0047] (2) The bismuth-doped quartz glass is welded on the end face of one side of the pure quartz glass tube. via H 2 / O 2 The oxyhydrogen flame of =2 is heated to the molten state of 1600-1800 ℃;

[0048] (3) The bismuth-doped quartz glass in the molten state is rapidly placed in deionized water at 25°C and completely soaked, and then rapidly quenched;

[0049] (4) Take out the quenched sample, process it into a predetermined size, polish both sides, and then clean and dry

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com