Surface performance regulator suitable for non-copper-plated welding wire and preparation method of surface performance regulator

A technology of surface properties and modifiers, which is applied in the direction of lubricating composition and petroleum industry, etc., can solve the problems of welding wire nozzle clogging the wire feeding pipe, etc., and achieve the effects of reducing the harm to the human body and the environment, reducing defects in the welding process, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

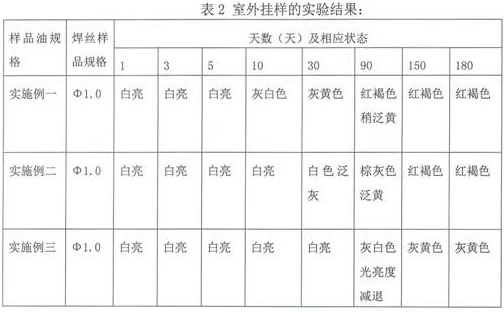

Examples

Embodiment 1

[0024] A kind of surface performance modifier suitable for non-copper-plated welding wire in the embodiment one is made up of the following raw materials by mass percentage: dodecane as solvent oil is 74%, and calcium petroleum sulfonate as rust inhibitor is 10%. %, 0.5% of benzotriazole, 8% of cottonseed oil as lubricant, 5% of polyisobutylene, 1% of microcrystalline wax as film-forming agent, 0.3% of T264 as antioxidant, as The sulfurized isobutylene of the extreme pressure antiwear agent is 0.5%, and the T151 of the dispersant is 0.7%.

[0025] A method for preparing a surface property modifier suitable for a non-copper-plated welding wire in Embodiment 1 is achieved through the following steps:

[0026] A, take by weighing calcium petroleum sulfonate, benzotriazole, cottonseed oil, polyisobutylene, dodecane, microcrystalline wax, T264, sulfurized isobutylene, T151 according to the raw material composition mass percent of described surface performance modifier;

[0027] B,...

Embodiment 2

[0032] A kind of surface property modifier that is applicable to non-copper-plated welding wire in embodiment two is made up of the raw material of following mass percentage: the dodecane as solvent oil is 81%, and the magnesium petroleum sulfonate as rust inhibitor is 6%. %, 0.3% of benzotriazole, 2.3% of soybean oil as lubricant, 3% of tea tree oil, 4% of polyisobutylene, 1.5% of microcrystalline wax as film-forming agent, T264 as antioxidant It is 0.5%, the sulfurized isobutylene as an extreme pressure antiwear agent is 0.6%, and the T151 as a dispersant is 0.8%.

[0033] A preparation method of a surface property modifier suitable for non-copper-plated welding wire of the second embodiment is achieved through the following steps:

[0034] A, take by weighing magnesium petroleum sulfonate, benzotriazole, soybean oil, tea tree oil, polyisobutene, dodecane, microcrystalline wax, T264, sulfurized isobutene, T151 according to the raw material composition mass percentage of the ...

Embodiment 3

[0040] A kind of surface performance modifier suitable for non-copper-plated welding wire in embodiment three is made up of the following raw materials by mass percentage: dodecane as solvent oil is 77%, calcium petroleum sulfonate as rust inhibitor 3% , 4% of magnesium petroleum sulfonate, 0.2% of benzotriazole, 2% of palm oil, 2% of cottonseed oil, 1% of soybean oil, and 7% of polyisobutylene as lubricants, microcrystalline as film-forming agent The wax is 1.2%, the T264 as an antioxidant is 0.6%, the sulfurized isobutylene as an extreme pressure antiwear agent is 1%, and the T151 as a dispersant is 1%.

[0041] A preparation method of a surface property modifier suitable for a non-copper-plated welding wire of the third embodiment is achieved through the following steps:

[0042] A, take by weighing calcium petroleum sulfonate, magnesium petroleum sulfonate, benzotriazole, palm oil, cottonseed oil, soybean oil, polyisobutylene, dodecane, microcrystalline Wax, T264, Sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com