Self-adhesive waterproof roll cementing material and waterproof roll prepared from same

A technology of self-adhesive waterproof membrane and waterproof membrane, which is applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., can solve the problems of poor flame retardancy of self-adhesive membranes, reduce temperature sensitivity, improve High temperature stability and aging resistance, effect of reducing thermal volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

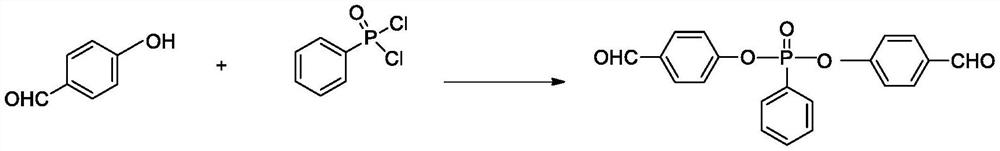

Method used

Image

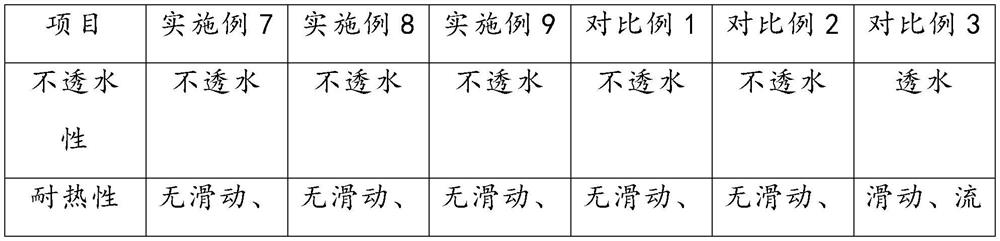

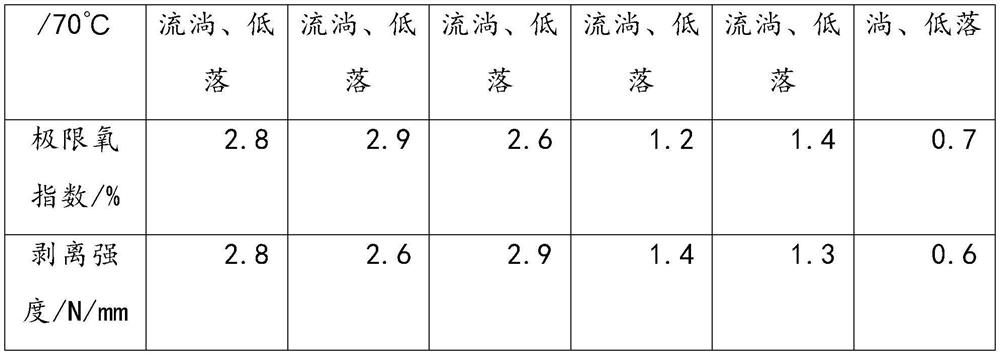

Examples

Embodiment 1

[0029] Organically modified nano palygorskite comprises the following steps:

[0030] A1. Mix 10 mL of HCl solution with a concentration of 0.1 mol / L and 3 g of palygorskite, stir vigorously in a 60°C water bath, and then stand, suction filtration to obtain a solid, wash the solid to neutrality, and vacuum dry at 110°C. to obtain pretreated palygorskite;

[0031] A2. Add 3 g of pretreated palygorskite into 280 mL of xylene, ultrasonically disperse for 0.5 h, add 3 mL of γ-aminopropyltriethoxysilane, heat up to 80 °C, stir at constant temperature for 10 h, and then filter, wash and After vacuum drying at 60°C, the organically modified nano-palygorskite was obtained.

Embodiment 2

[0033] Organically modified nano palygorskite comprises the following steps:

[0034] A1. Mix 15 mL of HCl solution with a concentration of 0.1 mol / L and 3.5 g of palygorskite, stir vigorously in a water bath at 60 °C, and then let stand, suction filtration to obtain a solid, wash the solid to neutrality, and vacuum dry at 110 °C , to obtain pretreated palygorskite;

[0035] A2. Add 4g of pretreated palygorskite into 300mL of xylene, ultrasonically disperse for 0.5h, add 4mL of γ-aminopropyltriethoxysilane, heat up to 80°C, stir at constant temperature for 10h, and then filter, wash and After vacuum drying at 60°C, the organically modified nano-palygorskite was obtained.

Embodiment 3

[0037] Organically modified nano palygorskite comprises the following steps:

[0038] A1. Mix 20 mL of HCl solution with a concentration of 0.1 mol / L and 4 g of palygorskite, stir vigorously in a water bath at 60 °C, then let stand, and filter the solid to obtain a solid. Wash the solid to neutrality, and vacuum dry at 110 °C. to obtain pretreated palygorskite;

[0039] A2. Add 5g of pretreated palygorskite into 320mL of xylene, ultrasonically disperse for 0.5h, add 5mL of γ-aminopropyltriethoxysilane, heat up to 80°C, stir at constant temperature for 10h, and then filter, wash and After vacuum drying at 60°C, the organically modified nano-palygorskite was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com